Part No. 890034 Form No. F101000A

Page 8 of 12

MAINTENANCE

CHIPPER BLADE REMOVAL AND SHARPENING-TKD ONLY

Depending on the type and amount of wood being chipped, the

chipper blade will eventually get dull, losing it’s cutting ability.

Evidence of a dull blade is a noticeably reduced chipping ability or a

rough cut on end of branch.

Note:

The chipper blade gap is factory set and should be checked

each time impeller is removed from engine crankshaft and reset if

required. If reassembly requires a different quantity of shim washers,

Billy Goat

®

shim washer must be used.

Chipper blades are normal replaceable wear items.

DANGER

Chipper blade is sharp.

Replace any damaged blade.

10.

Using a 3/16" Allen wrench and 1/2" open end wrench, remove

chipper blade from impeller.

11

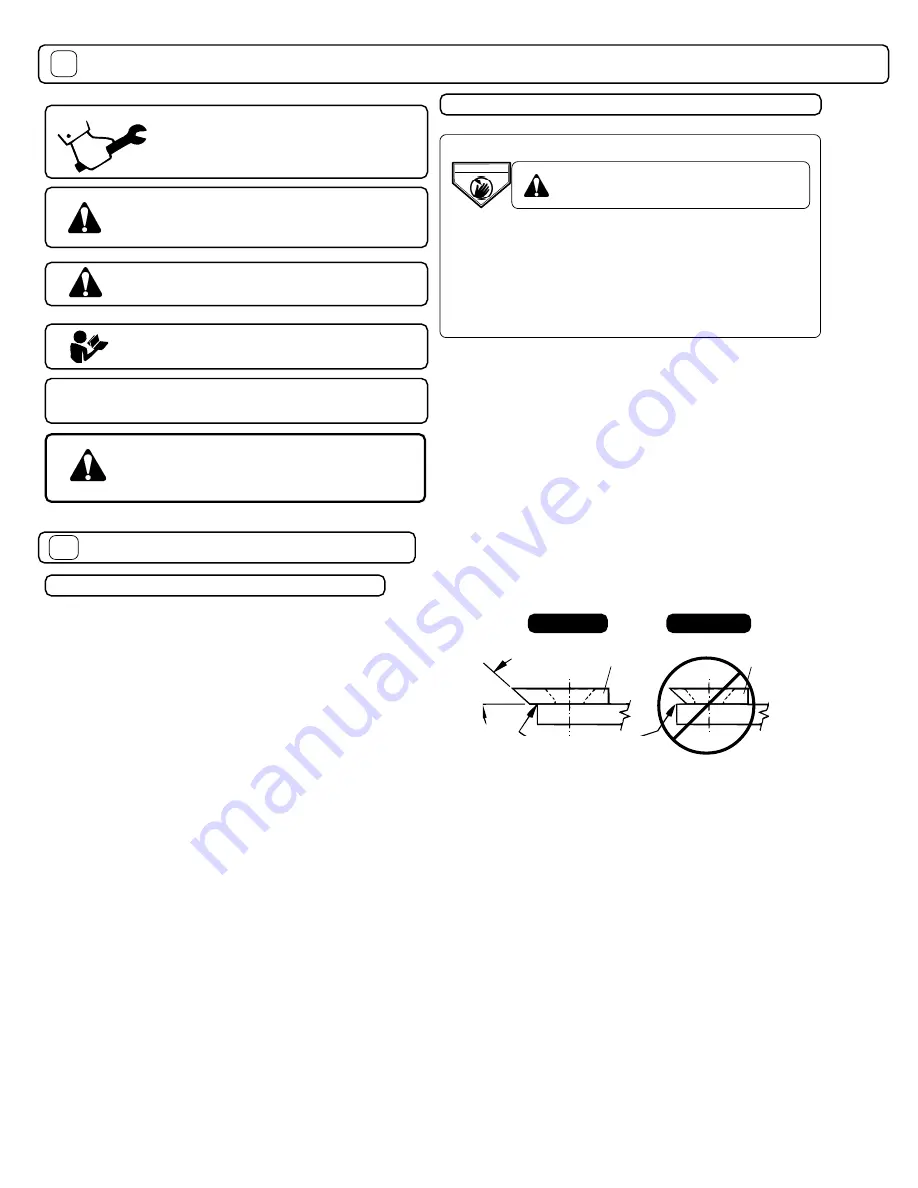

. Sharpen blade by lightly grinding the cutting edge of the blade

at

40 degrees

(see fig. 5). It is not necessary to remove all nicks

from the cutting edge.

CAUTION:

Be careful to avoid heat buildup

in the blade during sharpening. This will reduce it’s heat- treated

hardness properties and will reduce blade life. Evidence of too

much heat build-up is a change of color along sharpened edge.

12

. The same chipper blade can be sharpened several times.

However, blade replacement is required when blade no longer

overhangs the chip relief hole in impeller back plate or if increased

vibration occurs (see fig. 5).

13.

Chipper blade installation is in reverse order of removal.

40

o

Blade

Blade

INCORRECT

CORRECT

14

. To reinstall impeller, use a new impeller bolt and lockwasher

and use exactly the same crankshaft impeller shim washers as

were removed during disassembly (unless they were damaged).

Note:

your unit may or may not have required the use of shim

washers

.

15

. Tighten impeller bolt. Torque impeller bolt to 50 Ft. Lbs. (68 N.m)

(see item 51 on page 11).

16

. Slowly rotate impeller to insure proper chipper blade clearance.

Check to see that gap between chipper blade and anvil surface (on

lower side of housing top plate) measures between

0.040"(1.02mm) and 0.080"(2.03mm).

17.

If gap is less than 0.040"(0.51mm), add shim washer 890130

(0.060"{1.52mm} thick) and/or 890131 (0.020"{1.02mm} thick),

whichever is required. If gap is more than 0.080"(2.03mm), remove

one or more shim washers as needed to obtain correct gap (see fig.

6 & fig. 7). The chipper will function at up to a maximum of

0.125"(3.18mm) gap.

EDGE OF CHIP

RELIEF HOLE

Fig. 5

IMPELLER REMOVAL

and

CHIPPER ADJUSTMENT

1.

Wait for engine to cool and disconnect spark plug.

2

. Drain fuel and oil from the engine.

3.

Remove bag, quick release, and upper handle. Do not kink,

stretch, or break control cables, control housings, or end fittings while

removing handles.

4

. Remove housing top plate by removing bolts around outside of

housing.

5.

Leaving engine fastened to top plate, remove impeller bolt and

lock washer and slide impeller off crankshaft ( A puller may be

required).

6

. Retain shim washers used at end of crankshaft for use at impeller

reinstallation (see fig. 7). However, your unit may or may not have

required the use of shim washers.

7.

If impeller slides off freely, proceed to (step 11 or step 15).

(Do not drop impeller)

.

8.

If impeller does not slide off crankshaft, place two crowbars

between impeller and housing on opposite sides. Pry impeller away

from engine until it loosens.

Using a penetrating oil can help loosen a

stuck impeller.

9.

If the impeller cannot be loosened, obtain a 1” (25.4mm) longer

bolt of the same diameter and thread type as the impeller bolt. Invert

engine and impeller and support engine above ground to prevent

recoil damage. Thread longer bolt by hand into the crankshaft until

bolt bottoms. Using a suitable gear or wheel puller against the bolt

head and the impeller back-plate (near the blades), remove impeller

from shaft.

IMPELLER REMOVAL

Use only a qualified mechanic for

any adjustments, disassembly or

any kind of repair .

DISCONNECT SPARK PLUG WIRE

BEFORE SERVICING UNIT.

WARNING: TO AVOID PERSONAL INJURY, ALWAYS

TURN MACHINE OFF, MAKE SURE ALL MOVING

PARTS COME TO A COMPLETE STOP.

RECONNECT SPARK PLUG WIRE,

GUARDS, BAG, CAPS AND / OR

HOSE BEFORE STARTING ENGINE.

ENGINE: See engine manufacturer

operator's instructions.

DEBRIS BAG:

See page 6.

17.1

17

DANGER

DANGER

KEEP HANDS and FEET AWAY

KEEP HANDS and FEET AWAY