OPERATION

Fig. 21

2. Select the proper drill bit based on the hole size desired.

For large holes, drill a pilot hole first, using a smaller diameter

bit.

3. Select and set the recommended spindle speed. Refer to

“Changing Speeds” in the Adjustments section of this manual.

4. Set table assembly to desired height. Refer to “Adjusting

Table” Height in the Adjustments section.

5. If desired, set feed shaft at desired spindle depth. Refer to

“Adjusting Depth Gauge” in the Adjustments section.

6. Make sure the work table is free of all loose objects and

the bit is not in contact with the workpiece.

7. Plug electrical cord into power supply and turn switch ON.

Make sure spindle rotates freely.

8. Slowly lower drill bit into workpiece. Do not force the bit;

let the drill press do the work.

9. Once the hole is completed, allow the spindle to return to

its normal position. This will automatically raise the chuck

and bit.

If a large hole is needed, it’s a good idea to drill a smaller pilot

hole before drilling the final one. Your hole will be more

accurately positioned, rounder, and the bits will last longer.

If the hole is deeper than it is wide, back off occasionally to

clear the chips.

When drilling metal, lubricate the bit with oil to improve drilling

action and increase bit life.

As you increase the drill size, you may need to reduce the

spindle speed.

If drilling a through hole, make sure that the bit will not drill into

the table after moving through the workpiece.

DRILLING TIPS

Clamp

Scrap wood

Workpiece

18

Summary of Contents for 10-INCH

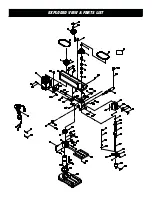

Page 23: ...EXPLODED VIEW PARTS LIST...