KBF + KMF (E6) 07/2017

page 80/155

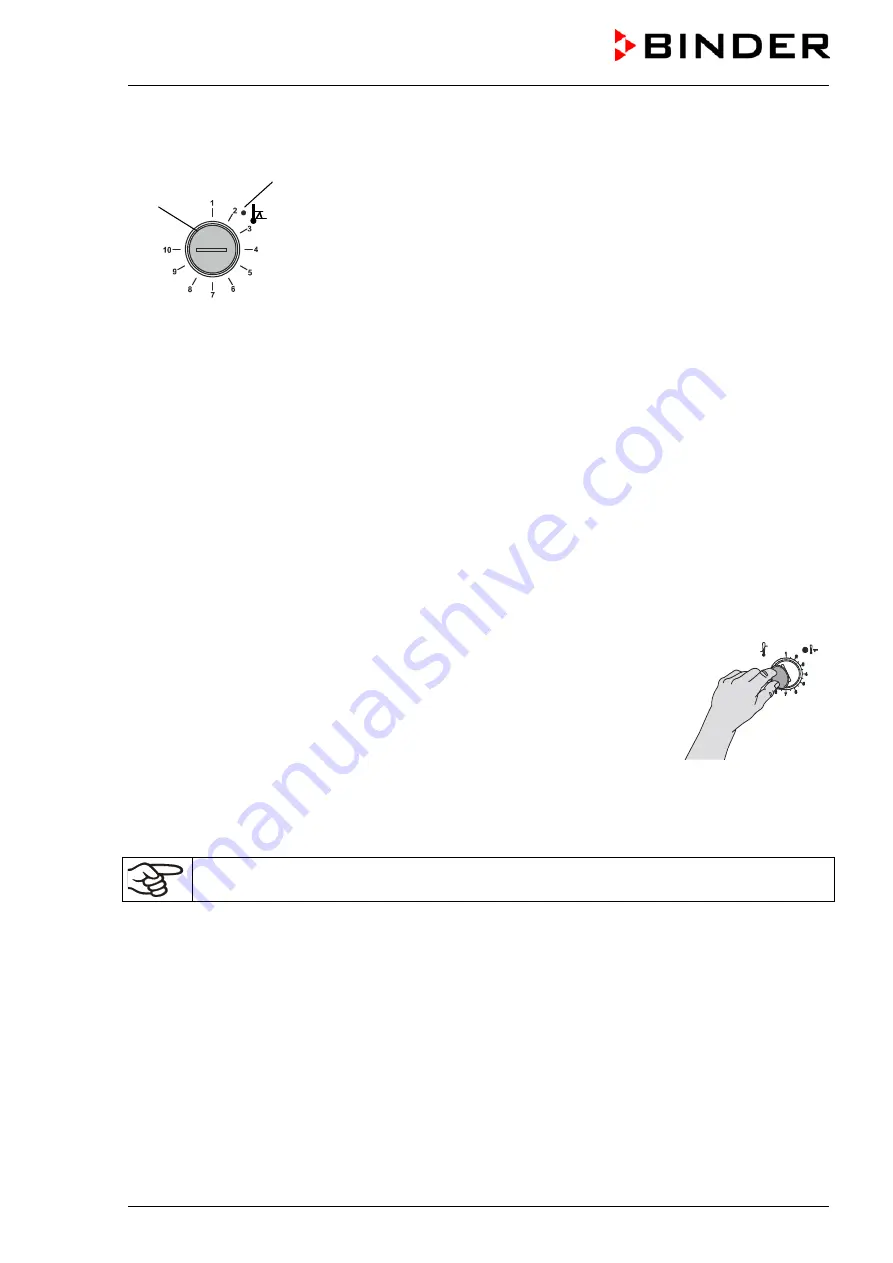

12.3.2 Temperature safety device class 3.2

The safety device class 3.2 is equivalently set to a minimum temperature the

chamber will not fall below. This protection against prohibited low tempera-

tures can, for example, serve to protect sensitive cultures from cooling down

too much.

If the control knob (9) is turned to its minimum (position 1), the safety device

class 3.2 has no effect. If it is set to a temperature somewhat lower than that

selected by means of the controller, it functions as a protective device for the

material under treatment.

If the temperature safety device class 3.2 has assumed regulation, identifiable by the red alarm lamp (9a)

lighting up, the message “Temp. safety device” on the controller display, and the buzzer sounds, please

proceed as follows:

•

Reset the buzzer with the “RESET” key on the controller.

•

Disconnect the chamber from the power supply.

•

Have an expert examine and rectify the cause of the fault.

•

Start up the chamber again

Setting:

To check the response temperature of the safety device class 3.2, put the chamber into operation and set

the desired set point at the temperature controller.

The sections of the scale from 1 to 10 correspond to the temperature range from -40 °C /

-40 °F

to +160

°C /

320 °F

and serves as a setting aid.

•

Turn the control knob (9) of the safety device by means of a coin to position 1

(thermostat without effect).

•

When the set point is reached, reset the safety device to its trip point (turn it

clockwise).

•

The trip point is identifiable by the red alarm lamp (9a), the message “Temp.

safety device” on the controller display, and the buzzer sounds. Reset the

buzzer with the “RESET” key on the controller.

•

The optimum setting for the safety device is obtained by turning the control

knob counter-clockwise by approximately two scale divisions, which shuts off

the red alarm lamp (9a).

Figure

18: Setting

safety device class 3.2

Check the setting regularly and adjust it following changes of set-point or charge.

Function check:

Check the temperature safety device class 3.2 at appropriate intervals for its functionality. It is recom-

mended that the authorized operating personnel should perform such a check, e.g., before starting a

longer work procedure.

(9a)

(9)

Summary of Contents for KBF 115

Page 137: ...KBF KMF E6 07 2017 page 137 155 23 8 Dimensions size 115 ...

Page 138: ...KBF KMF E6 07 2017 page 138 155 23 9 Dimensions size 240 ...

Page 139: ...KBF KMF E6 07 2017 page 139 155 23 10 Dimensions size 720 ...

Page 140: ...KBF KMF E6 07 2017 page 140 155 23 11 Dimensions size 1020 ...

Page 142: ...KBF KMF E6 07 2017 page 142 155 ...

Page 143: ...KBF KMF E6 07 2017 page 143 155 ...

Page 144: ...KBF KMF E6 07 2017 page 144 155 24 2 EU Declaration of Conformity for KMF ...

Page 145: ...KBF KMF E6 07 2017 page 145 155 ...

Page 146: ...KBF KMF E6 07 2017 page 146 155 ...

Page 148: ...KBF KMF E6 07 2017 page 148 155 ...

Page 149: ...KBF KMF E6 07 2017 page 149 155 25 Product registration ...