Page 9

Application Technique

When spraying try to keep the gun HAP 50 parallel to the target. Twisting your wrist or arcing will

make the coating irregular. The gun must be hold with the whole arm.

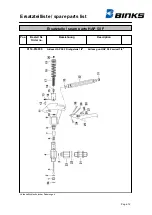

The BINKS Airless Spray Gun has been factory tested. The unit comes assembled except for the

selected tip which must be installed. We recommend, however, to perform the following steps:

1. Start the pump slowly without spray tip and circulate the fluid, so that air may escape off the

system.

2. Release the trigger, put in trigger guard, and install the spray tip.

3. Increase the pump pressure and check spray pattern for proper atomization.

Unnecessary high pressure will result in premature wear of parts !

4. Keep the gun approximately 20 to 36 cm from the target.

5. If the fluid pressure is too high or the tip is obstructed or damaged this will cause a heavy pattern

on top or bottom.

6. If the fluid pressure is too low, or the fluid has a higher viscosity, or you are using the wrong tip

this will cause stripes or a faulty pattern.

7. Airless guns are either at the "ON" or "OFF" position. Intermediate positions known at

conventional air atomizing guns are not possible.

8. With Airless spraying there will be a heavier material build up at the sides. Therefore, the overlap

can be kept small.

9. Due to the high fluid flow the spray courses have to be performed quicker than with air atomizing

guns.

Important:

Shut the gun at each change of direction. If the spray pressure is too low and/or the

tip is too large and/or the viscosity is too high this will cause stripes at the edges. In order to

avoid a pattern with stripes at the edges increase the pressure, use a smaller tip, or dilute

the material.

Cleaning and Maintenance Procedures

Always remove the spray tip before flushing the Airless system. At the same time let the pump run

at lowest possible pressure.

The gun should be thoroughly flushed through with an appropriate solvent after use. In order to

avoid sticking of the valve stem to the packing rinse again with turpentine substitute.

In order to avoid sticking of the valve needle perform the following: Pull back the trigger of the

completely relieved gun and lubricate the needle with a single drop of non-resinous, silicone-free oil

from time to time.

Clean the gun filter depending on the material used either with solvent or water and a hard brush.

Never use a steel brush.