11

Your new Binks Century Gun will give you excellent performance

as long as it is handled properly. Read over these sections before

operating the gun.

CATALYZATION

The catalyst orifice should be sized to minimize catalyst pres-

sure. Over-catalyzation can show up as a split pattern, misting

of the resin, streaking of the catalyst in the resin, or detection

of catalyst fumes. A wide range of catalyst injectors is avail-

able to accommodate your specific needs. Refer to the

Catalyst

Injector Selection Chart

for the various orifice sizes.

Catalyst fumes should be minimal. The Binks Century guns

utilize external advanced catalyzation technology, “EXACT”

which mixes all of the catalyst exiting the catalyst injector into

the resin stream.

FLUID/AIR PRESSURE OF THE RESIN/GEL-COAT

To reduce overspray and obtain maximum efficiency of the

Century gun, the fluid and air pressure should be reduced to

their lowest possible pressures that produce acceptable

atomization and finish.

Typically, for unfilled resins and unpigmented gel-coats, the fluid

pressure needed for proper atomization is approximately 200-700

psi. For filled resins and pigmented gel-coats, the fluid pressure

will be significantly higher, approximately 400-1500 psi.

Depending on your system, the fluid pressures you use will vary

higher or lower than these numbers, but they serve as a good

starting point.

Typically, the pressure setting at nozzle for the atomizing air

will be from 3 to 10 psi, although pressures up to 30 psi are

acceptable. The atomizing air is necessary for proper catalyza-

tion and therefore should not be reduced below 5 psi. Also,

depending upon the catalyst, it may be necessary to

increase/decrease the atomizing air in order to induce proper

catalyzation after determining the necessary air pressure for a

good spray pattern.

TIMING OF THE AIR, CATALYST AND

RESIN VALVES

The timing of the air, catalyst and resin valves is an important

factor in the operation of the Century gun.

The gun will appear to leak if the lag between engaging the

atomizing air and the fluid needles is unnecessarily long.

While releasing the trigger, the resin and catalyst shut off first

and the atomizing air has not shut off yet. The atomizing air

will then siphon out any remaining material in the spray tip

and/or catalyst injector. This is why it is necessary to adjust the

nuts on the resin and catalyst needles so that there exists only a

very short interval between the actuation of the atomizing air

and the fluid needles.

(continued)

OPERATING INSTRUCTIONS

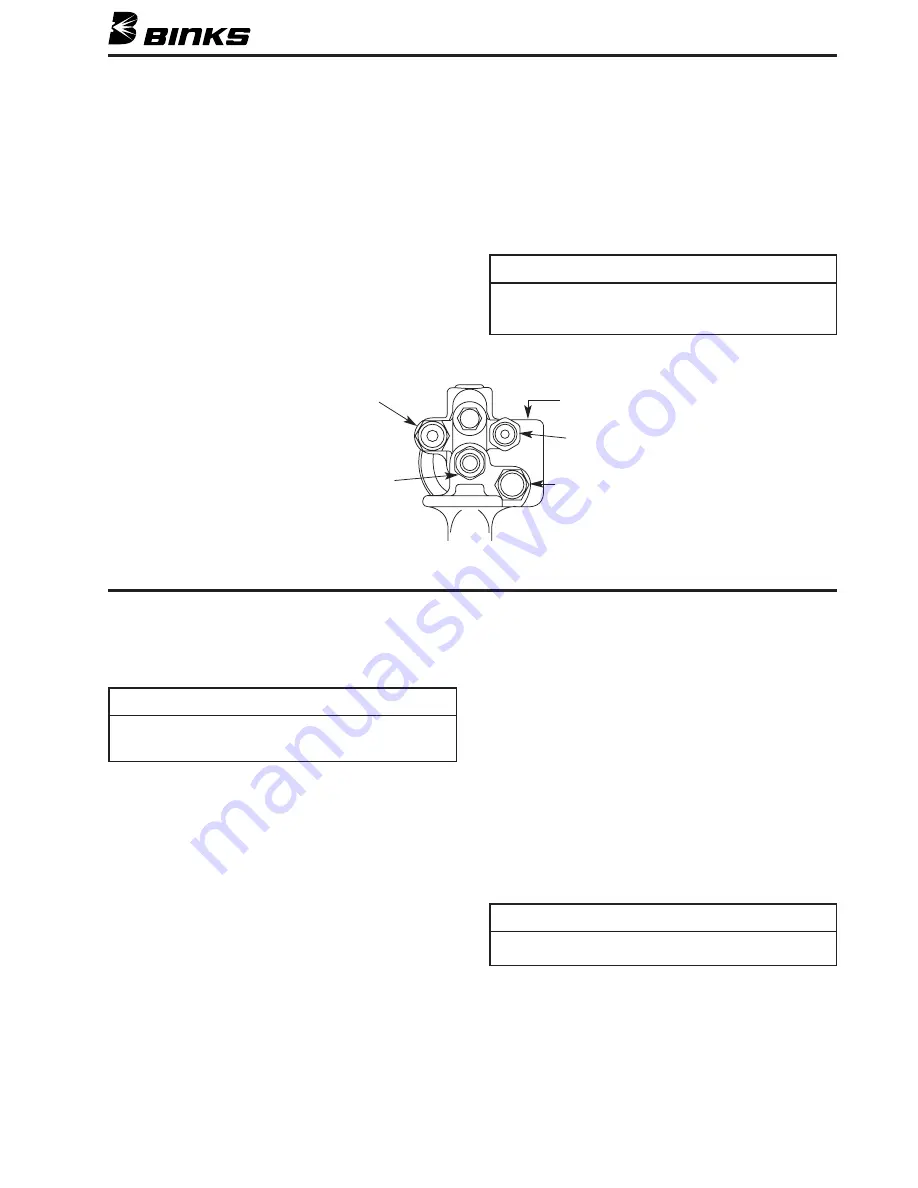

REAR VIEW OF GUN

NOTE: All inlets are 1/4" male.

(For 102-2400, 102-2455 and 102-2500)

Resin

Inlet

Air Assist

Inlet

Chopper Air

Outlet

Catalyst

Inlet

Chopper Air

Inlet

1. Connect air hose to air assist inlet (53) and tighten securely.

Set regulator to provide sufficient air at nozzle (3-10#).

2. Connect high pressure airless fluid hose from the resin

pump to the resin inlet assembly (48) and tighten securely.

Set pumping source to deliver resin from 500-1500 psi.

3. Connect the catalyst hose to the catalyst inlet/filter assem-

bly (42) and tighten securely.

4. If using chopper (102-2400 gun), connect the chopper air

hose to the chopper air inlet (52) and tighten securely.

5. Loosen the two nuts on the catalyst needle (24 & 25) and

move them forward so that the trigger actuates them simul-

taneous with engagement of the resin needle. Once fin-

ished, reposition them again so that they are engaged just

as the resin needle nut is engaged when triggering the gun.

6. Assemble the spray tip assembly and the air/catalyst cap

and tighten the air/catalyst cap retainer ring (1) securely.

7. Set fluid pressure to achieve low pressure airless pattern

with “fingers”.

8. Adjust atomizing air until the “fingers” have been removed

from the spray pattern and proper atomization has been

achieved. If atomizing air seems excessive (overspray)

increase fluid pressure and reduce air. (Check pattern).

(Excessive atomizing air can impair catalyzation.)

SET-UP INSTRUCTIONS

NOTE

Century guns are considered HVLP (high volume, low

pressure). Air required for atomization is in the 3-10#

range at nozzle.

NOTE

Whenever the gun is not in operation set the trigger lock by

rotating the trigger (62) as far forward as it will go and then

rotating the locking block (68) in its upward orientation.

NOTE

The sequence of operation is: atomizing air, catalyst and

resin simultaneously.