12

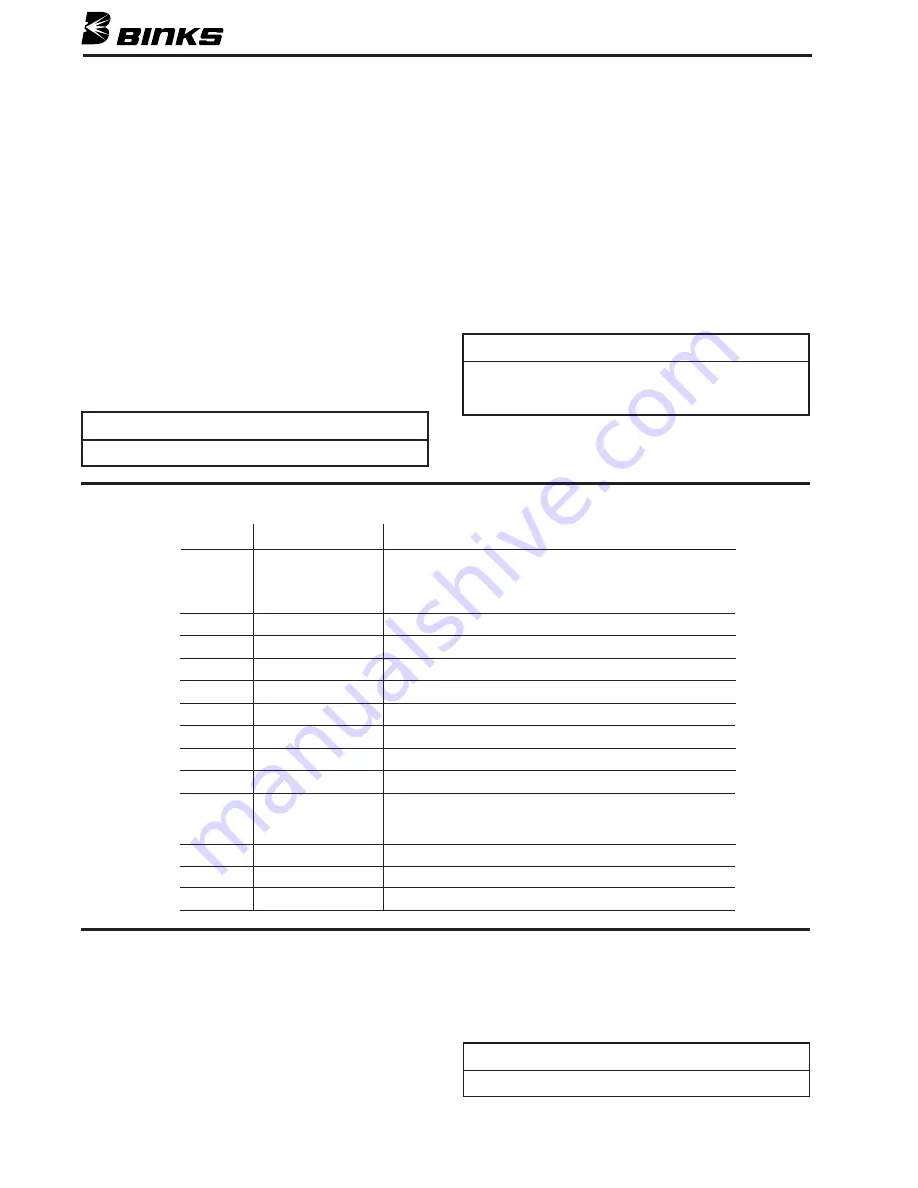

BINKS CENTURY GUN SUGGESTED SPARE PARTS

PART

QTY.

DESCRIPTION

NO.

PER PKG.

108-9XXYY

3

Tungsten Carbide Nozzle and 2 tip seals per nozzle.

(size determined by application) (See Tip Chart)

XX = Orifice size in thousandths

YY = Spray width at 12"

106-1170

See Description

Spare Parts Kits (2 sets of O-Rings, 1 set of Packings)

106-1171

1

Repair Kit, Fluid Valves/Seats

106-1172

1

Repair Kit, Air Valve

106-1173

15 sets

Kit, Nozzle O-Rings (20-4542, 20-6296)

106-1174

See Description

Soft Seat Kit (10 Resin, 5 Catalyst)

106-1175

5 sets

Catalyst Filter Repair Kit

106-1176

10

Tip Seal Kit (106-1176)

106-1177

10

Tip Seal Kit (102-2499)

102-25XX

1

Catalyst Injector

XX = orifice size in thousandths.

Actual size determined by application. (See injector chart)

102-2431

1

Air/Catalyst Cap

102-2432

1

Double Sided Air/Catalyst Cap Assembly

102-2494

1

Night Cap

However, it is very important that the atomizing air is turned

on first. Otherwise, initial catalyzation and spray pattern will

be poor upon triggering the gun.

VERIFICATION OF FLOW FOR

SUPER SLAVE AND UNISON

1. To set catalyst and resin ratio move bearing on catalyst

pump to desired percentage of catalyst labeled on slave

arm assembly.

2. With air assist air off, place air/catalyst cap on the gun.

CALIBRATION FOR PRESSURE TANK

1. With air assist air off, place air/catalyst cap and tip on the

gun and catch ratio.

2. Adjust tank pressure to vary ratio (see manufacturer’s

specifications). Once ratio is set, record air pressure to

both Tank and air motor, and ball level on flow meter. If

shop temperature does not vary, flow will remain constant.

CHOPPER TRIGGER OPERATION

(102-2400 GUN ONLY)

The Century gun is equipped with a special chopper trigger (54).

This device allows simple on/off capabilities plus the ability to

run/load the chopper without triggering the gun at all. To set the

chopper trigger to its “on” position rotate the on/off selector (56)

as far clockwise as it will go. To set the chopper trigger to its

“off” position simply rotate the on/off selector as far counter-

clockwise as it will go. To run the chopper without triggering the

gun and, with the gun in your right hand, set the on/off selector

to “on”, place your right index finger on the trigger pad of the

chopper trigger sub-assembly (55) and pull back on the chopper

trigger until the chopper air valve (26) is engaged.

OPERATING INSTRUCTIONS

(continued)

GENERAL MAINTENANCE

DAILY INSPECTION

1. Inspect the gun head o-rings (7 & 8) for cuts or tears and

replace if necessary.

2. Check the fluid needles (11 & 19) for signs of material

leakage. Tighten fluid packing nuts if leaks are present

until leakage stops. If leak does not stop replace the needle

packing or needle.

3. Inspect the tip seal (6) for wear or damage and replace

if necessary.

4. Inspect filters of system for build-up and clean if

necessary.

NOTE

With tip wear, resin flow will slowly increase.

NOTE

This can also be done by a left-handed operator, but it is

a little difficult to reach under the bridge of the handle to

actuate the chopper trigger.

NOTE

Do not soak o-rings in solvents (swelling will occur).