15

REPLACEMENT OF WORN PARTS (

continued

)

REPLACING THE RESIN NEEDLE PACKING

1. Remove the button head screw (65) that retains the guard

assembly (64) by using a 3/16" allen wrench; remove the

guard assembly.

2. Using two standard screwdrivers, remove the trigger stud

(60), the trigger screw (61), the trigger (62), and the chop-

per trigger assembly (54).

3. Using 3/8" wrench or socket, remove the head retainer (51).

4. Slide the gun head (9) as far forward as it will go with your

hands. Do not use excessive force.

5. Unscrew the resin packing nut (15) with a 3/8" wrench and

pull the resin needle assembly (11) straight back until it

comes out of the gun head. Be sure to pull the needle out

without bending it up or down or side to side as this will

cause the needle to bend, thus ruining the needle.

6. Clean the needle assembly so that you may be able to

clearly identify the packing (13).

7. The packing is the only non-metal piece of the needle

assembly and is white in color. Note its location and orien-

tation on the wire of the needle. Cut the worn packing away

with a sharp knife being sure not to scratch or deform any

nearby parts.

8. Carefully spread the new packing apart, about 3/64" at the

edge (this can be done easily with an X-acto type knife) and

press the packing onto the wire of the needle assembly in

the same location and orientation as noted in step 7. Gently

squeeze the packing closed with fingers.

9. Slide the packing forward and back with your fingers to

assure a proper fit onto the wire.

10. Reassemble in reverse order.

REPLACING THE RESIN NEEDLE ASSEMBLY

1. Repeat steps 1 thru 5 from section

“Replacing the Resin

Needle Packing”

above.

2. Replace worn needle assembly with new needle assembly.

3. Reassemble in reverse order.

REPLACING THE CATALYST NEEDLE ASSEMBLY

1. Repeat steps 1 and 2 from the section

“Replacing the

Catalyst Needle Packing”

above.

2. Replace worn needle assembly with new needle assembly.

3. Reassemble in reverse order.

REPAIRING THE AIR ASSIST VALVE ASSEMBLY

1. Repeat steps 1 and 2 from section

“Replacing the Resin

Needle Packing.”

2. Using a 9/16" wrench remove the air assist valve assembly

(33), seal (38), and spring (39).

3. Remove the nut (34) from the body (36); the packing (35)

can be replaced if necessary.

4. Remove and inspect the valve assembly (37) from the body

and replace if necessary.

5. Replace the spring if necessary. Replace the seal (38) and

reassemble in reverse order.

REPAIRING THE CHOPPER AIR VALVE ASSEMBLY

1. Repeat step 2 from section

“Replacing the Resin Needle

Packing”

.

2. Remove the chopper valve assembly (26), from the

handle (41).

3. Using a screwdriver, remove the screw (86) from the

chopper valve assembly (26).

4. Manually pull and remove the screw (28), with attached

components from the air valve body (84).

5. Remove and replace the o-ring, (29), from the stem (88).

6. Lubricate the o-ring and inside surface of the air valve body

(84) with petroleum jelly.

7. Re-assemble the chopper air valve in the reverse order.

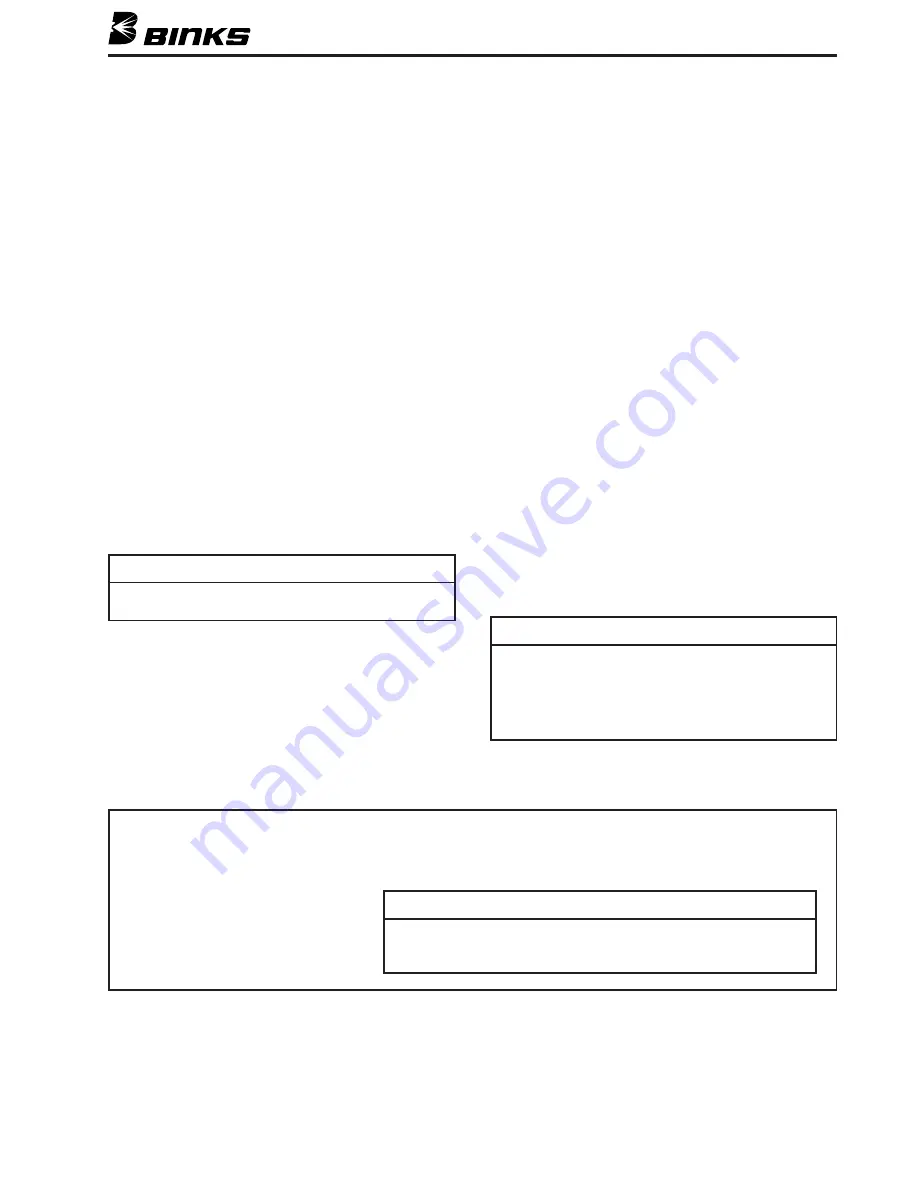

Assembly

Orifice

Gel/Resin

Number

Size

Tip Sizes

102-2513

.013

.013 - .018

102-2515

.015

.015 - .021

102-2518

.018

.015 - .021

102-2521

.021

.021 - .031

102-2526

.026

.026 - .043

102-2531

.031

.031 - .052

102-2536

.036

.043 - .072

NOTE

The cone face of the packing should point towards the

ball of the needle assembly.

NOTE

These are general recommendations. Due to variations in viscosities of

catalyst and resin (Gel-Coat), actual optimal sizing may differ. The intent

is to optimize mix by minimizing catalyst pressure.

NOTE

Periodic lubrication of the chopper air valve assembly is

necessary to ensure smooth operation.

The OLD style chopper air valve assembly (102-2618) is

no longer supported by Binks. Contact Binks to obtain the

NEW style chopper air valve assembly.

CATALYST INJECTOR SIZING CHART