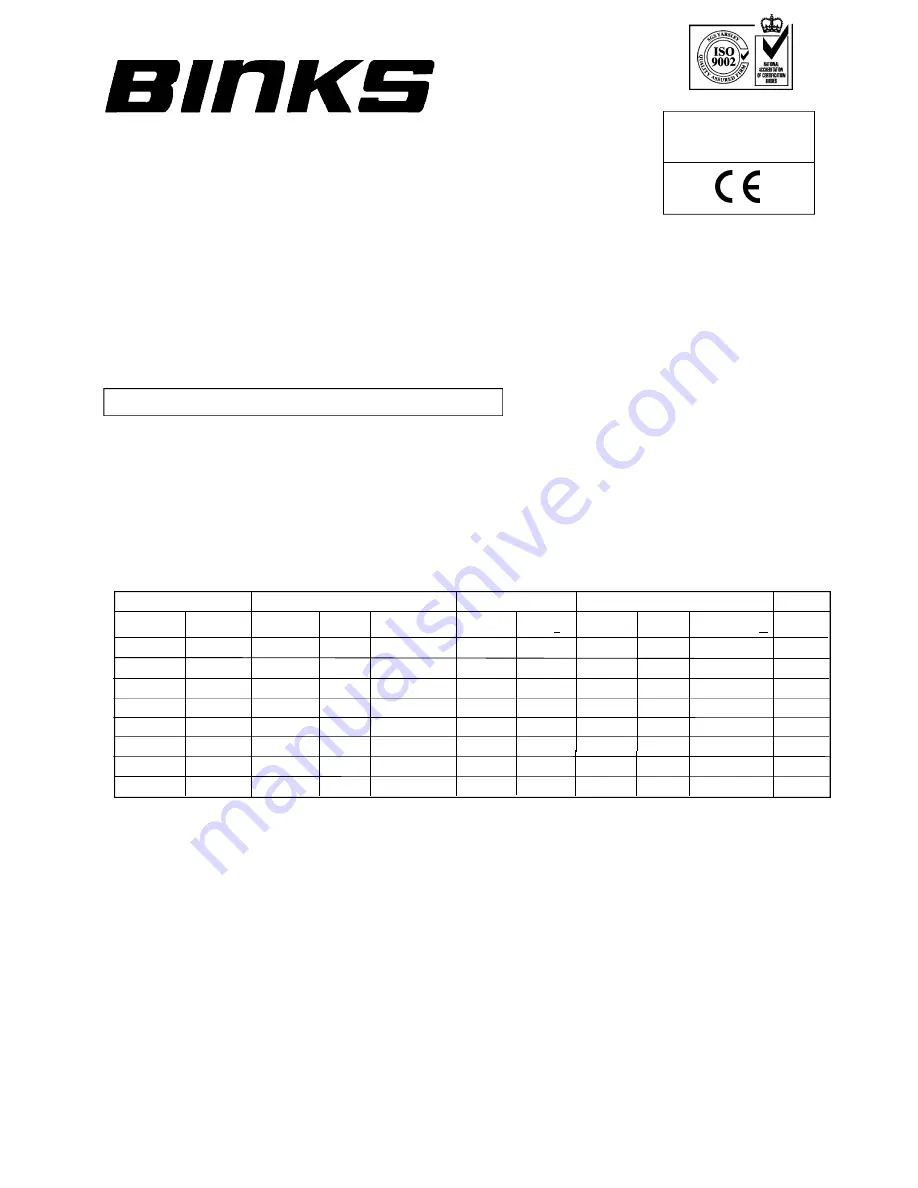

SPRAYGUN

MATERIAL NOZZLE

NEEDLE

AIR NOZZLE

GROUP

PART N

o

THREAD PART NO CODE BORE PART NO

MAT

L

PART NO CODE AIR CONS

N

100104

BSP

200316

71

0.071”,1.8mm 180123

ST ST

200885

66SD1

(16.2) [27.5]

1

100114

BSP

200338

446

0.046”,1.1mm 180100

NYLON

200850

63PB

(18.9) [32.1]

1

100124

BSP

200315

60

0.060”,1.5mm 180124

ST ST

200885

66SD1

(16.2) [27.5]

1

100125

BSP

200338

446

0.046”,1.1mm 180117

ST ST

200850

63PB

(18.9) [32.1]

1

100126

BSP

200315

60

0.060”,1.5mm 180124

ST ST

200886

66S2

(6.3) [10.7]

1

100135

BSP

200315

60

0.060”,1.5mm 180124

ST ST

200850

63PB

(18.9) [32.1]

1

100176

BSP

200328

2086V 0.086”,2.2mm 180111

ST ST/

200865

67SA

(18.2) [30.1]

4

100188

BSP

200316

71

0.071”,1.8mm 180123

ST ST

200885

66SD1

(16.2) [27.5]

1

Operation Manual:

MODEL 230 PRESSURE/SIPHON FEED

HAND GUN

Important:

Read and follow all instructions and SAFETY PRECAUTIONS

before using this equipment

This is a production hand spray gun suitable for use with most solvent based coating materials. The performance of this gun is

achieved by a range of air nozzles combined with large, smooth flowing air passages and an oversize air valve which gives a lower

pressure drop. The gun is designed to be used with a siphon cup or material feed hose.

IMPORTANT:

These guns are not designed for use with highly corrosive or highly abrasive coating material and if used with such

materials it must be expected that the need for thorough cleaning and/or the necessity for replacement parts will be increased. If there

is any doubt regarding the suitability of a specific material, advise what material is to be used and/or submit a sample for test.

DESCRIPTION

SB-E-A1-2-8

©BINKS 1999

Chart 1

Ordering Information :

TUNG CARB

GROUP 1

Normal range of finishing materials from thin spirits to heavy enamels.

GROUP 4

Vitreous enamel. N.B Air nozzle can only be used with mat. Nozzles of the same group. Suffix “V” denotes tungsten carbide

tipped.

Figure in ( ) brackets is air consumption in c.f.m 63 psi

Figure in [ ] brackets is air consumption in m

3

/ hr at 63 psi