B41-818836conductiveacetal-rev0416

Model 41-818836 Conductive Acetal Ball Valve Pump Page 17

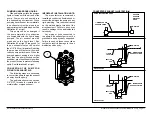

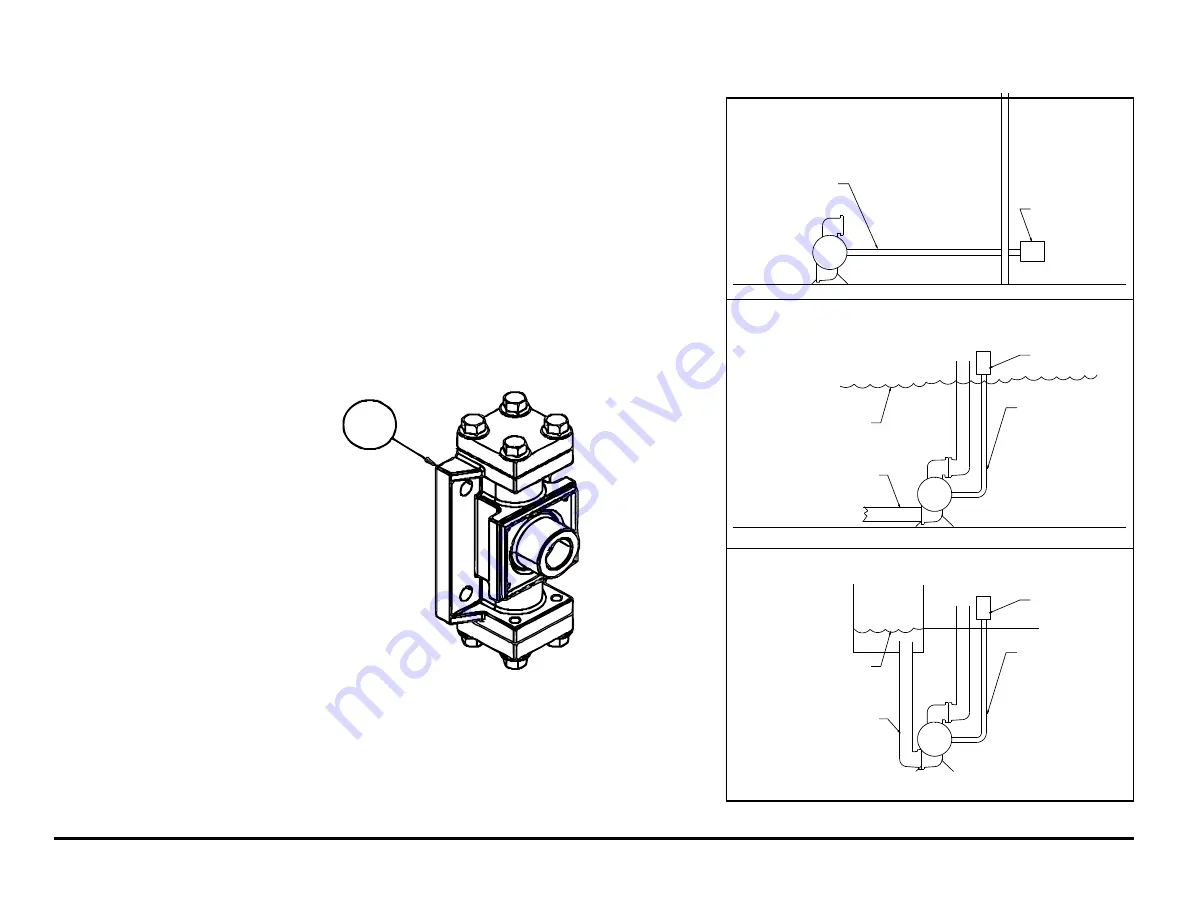

SAFE AIR

EXHAUST

DISPOSAL

AREA

PUMP INSTALLATION AREA

1" DIAMETER AIR

EXHAUST PIPING

1" DIAMETER AIR

EXHAUST PIPING

MUFFLER

LIQUID

LEVEL

SUCTION

LINE

LIQUID

LEVEL

SUCTION

LINE

MUFFLER

MUFFLER

1" DIAMETER AIR

EXHAUST PIPING

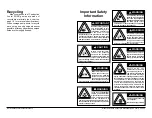

PUMPING HAZARDOUS LIQUIDS

When a diaphragm fails, the pumped

liquid or fumes enter the air end of the

pump. Fumes are exhausted into

the surrounding environment. When

pumping hazardous or toxic materials,

the exhaust air must be piped to an

appropriate area for safe disposal. See

illustration #1 at right.

This pump can be submerged if

the pump materials of construction

are compatible with the liquid being

pumped. The air exhaust must be

piped above the liquid level. See

illustration #2 at right. Piping used for

the air exhaust must not be smaller

than 1/2" (2.54 cm) diameter. Reducing

the pipe size will restrict air flow and

reduce pump performance. When the

pumped product source is at a higher

level than the pump (flooded suction

condition), pipe the exhaust higher than

the product source to prevent siphoning

spills. See illustration #3 at right.

CONVERTING THE PUMP FOR

PIPING THE EXHAUST AIR

The following steps are necessary

to convert the pump to pipe the exhaust

air away from the pump.

The air distribution valve body has

3/8" NPT threads for installation of

metal muffler or piped exhaust.

IMPORTANT INSTALLATION NOTE:

The manufacturer recommends

installing a conductive flexible hose or

connection between the pump and any

rigid plumbing. This reduces stresses

on the molded plastic threads of the

air exhaust port. Failure to do so may

result in damage to the air distribution

valve body.

Any piping or hose connected to

the pump’s air exhaust port must be

groundable and physically supported.

Failure to support these connections

could also result in damage to the air

distribution valve body.

CONVERTED EXHAUST ILLUSTRATION

Illustration #1

Illustration #2

Illustration #3

1