77-2019-R4.2 (8/2017)

4 / 8

EN

www.carlisleft.com

Approx. Air Consumption SCFM

with Specific Dynamic Air

Presure (PSI) at air cap

GUN MOUNTING

A hexagon screw (13) will secure the spray gun to the 54-380 gun

mounting rod. For special mountings, a 1/2" dia. rod will fir the hole

in the top of the gun body.

HOSE LENGTH

Install minimum hose length from valve to gun to minimize time

required for “off–on” response of gun.

CONNECTIONS

The air connection and fluid connection are both 1/4 NPS. The air con-

nection is stamped “a”.

AIR SUPPLY

Since the gun has its own control, atomizing air may be taken directly

from the main line. However, if regulated air is used, 50 PSI minimum

is required to actuate gun fluid valve piston. When rapid “off–on” oper-

ation is required, use a 3-way valve which exhausts to atmosphere, in

place of a 2-way valve.

SPRAY PATTERN

The width of spray pattern is controlled by the control assembly (26).

Vertical or horizontal position of the spray is obtained by rotating the

air nozzle.

ATOMIZATION

Air volume to the nozzle is controlled by the control assembly (26)

located adjacent to the air inlet connection.

FLUID CONTROL

The rate of fluid flow is controlled by a combination of the selection

of the correct nozzle orifice size and adjustment of fluid pressure. The

maximum fluid flow rate is approximately 8 fluid ounces per minute.

Fine adjustment of the fluid flow can be obtained by controlling the

travel of the needle valve. Clockwise rotation of the screw (24) decreases

the needle travel and counterclockwise rotation increases the travel.

The locknut (15) is used to lock the screw (24) after adjustment.

FAULTY SPRAY

Caused by improper cleaning, or dried fluid on nozzle tip or in the air

nozzle. Soak these parts in solvent to soften the dried fluid and remove

with a brush or cloth.

If either air nozzle or fluid nozzle is damaged, the part must be replaced

before a perfect spray can be obtained.

SPITTING

To eliminate spitting and dripping, turn on atomizing air before turning

on fluid.

NEEDLE ADJUSTMENT

The correct setting is to allow approximately 1/16" piston travel before

contacting NEEDLE. Adjustment is made by loosening the screw (17)

on rear of needle and rotating the spring guide (20) either forward to

reduce or back to increase clearance.

AIR LEAKAGE INTO AIR CYLINDER VENT

Remove piston (19) and inspect for dirt or damage to large o-ring (5).

Clean piston and cylinder. Replace o-ring if necessary. Lubricate with

white petroleum jelly.

AIR LEAKAGE AT FLUID NEEDLE

Remove piston (19) and inspect for dirt or damage to small o-ring (6).

Replace if necessary.

FLUID LEAKAGE AT PACKING GLAND

Tighten screw (10) and slightly “back-off” screw to set packing. If leakage

continues, replace packing.

CLEANING THE GUN

Under no circumstances should the complete gun be immersed in thin-

ners or solvents.

INSTALLATION, OPERATION & MAINTENANCE

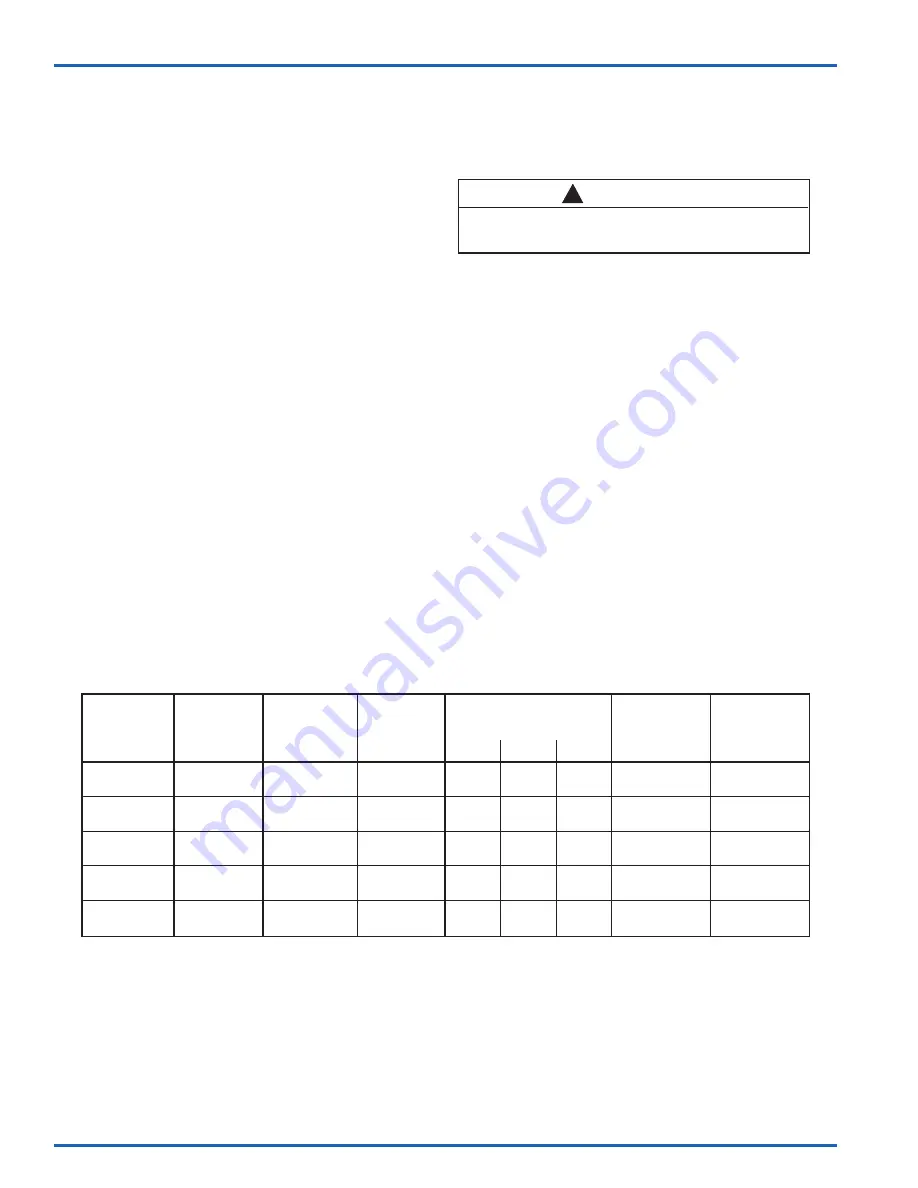

Binks MODEL 460 GUN FLUID NOZZLE, NEEDLE & AIR CAP SELECTION CHART

Type of

*Max. Spray

Spray

Pattern Size @

Fluid Nozzle

Orifice Size

Fluid Needle

Air Nozzle

30 PSI

50 PSI

70 PSI

Pattern

5" Distance

J920SS

.020"

940

J92P

ELLIPSE /

(PN 45-84)

(.5 mm)

(PN 47-454)

(PN 46-131)

6.4 8.5 10.5

STRAIGHT SIDES

6"

J930SS

.030"

940

J92P

ELLIPSE /

(PN 45-85)

(.75 mm)

(PN 47-454)

(PN 46-131)

6.4 8.5 10.5

STRAIGHT SIDES

7.5"

J940SS

.040"

940

J92P

ELLIPSE /

(PN 45-86)

(1.0 mm)

(PN 47-454)

(PN 46-131)

6.4 8.5 10.5

STRAIGHT SIDES

8"

J940SS .040"

940

J92R

(PN 45-86)

(1.0 mm)

(PN 47-454)

(PN 46-126)

4 6 8

ROUND

2"

K960SS

.060"

960

K92P

ELLIPSE /

(PN 45-87)

(1.5 mm)

(PN 47-455)

(PN 46-134)

7.2 10.6 14

STRAIGHT SIDES

9.5"

*Spray pattern for reference only. Pattern size will vary slightly with flow and viscosity of the materials.

CAUTION

Never use metal instruments to clean air or fluid nozzles.

These parts are carefully machined and any damage to them

will cause a faulty spray.

!