BINKS MODEL 550 AUTOMATIC AIRLESS SPRAY GUN

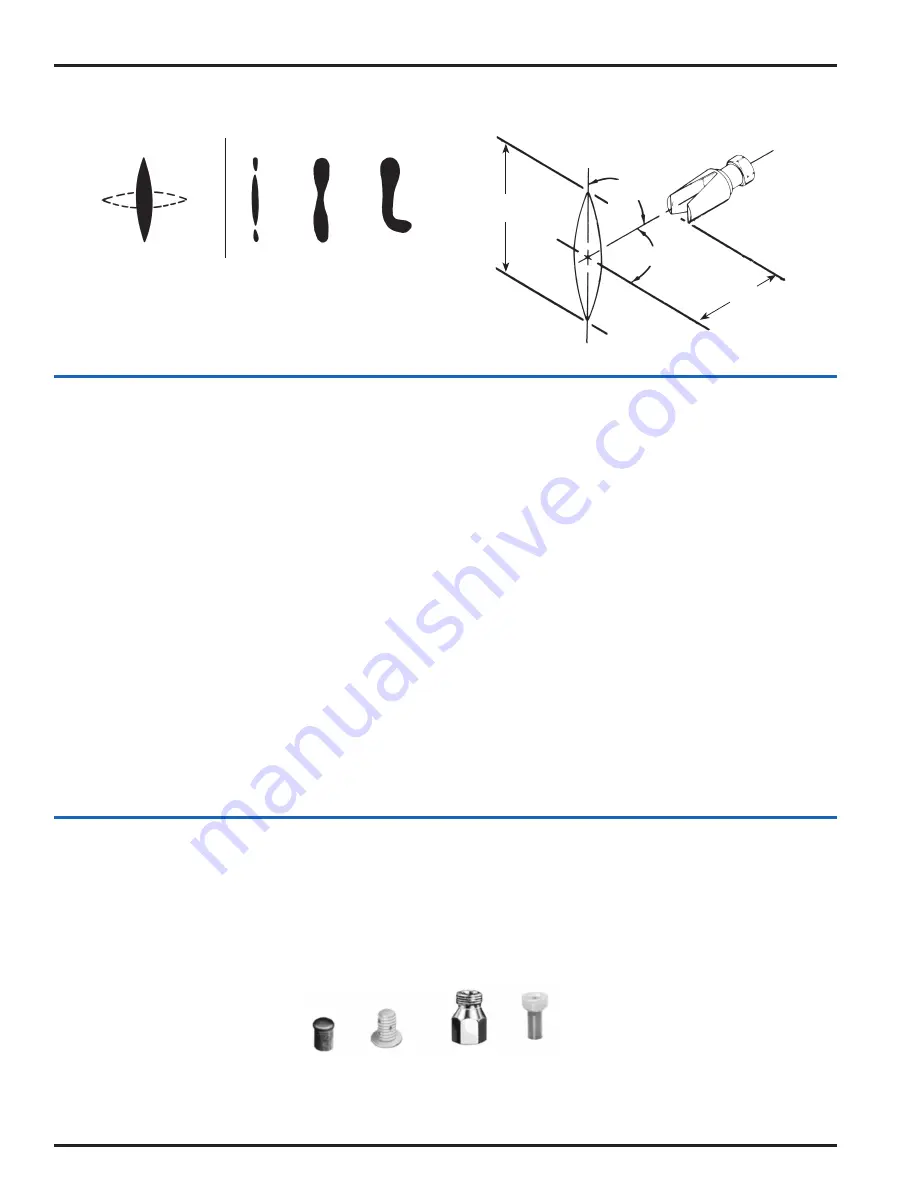

INCORRECT PATTERNS

CENTER LINE

OF

GUN

“TAILS”

“HOURGLASS”

“DISTORTION”

90˚

90˚

MAXIMUM

FAN WIDTH

8"

to

14"

MAINTENANCE INSTRUCTIONS

(See High Pressure Warning Statement on Page 1)

TO CLEAN NOZZLE TIP:

1. BEFORE proceeding with any maintenance,

read safety procedure, paragraph 3, in High

Pressure Warning, page 1.

2. Remove tip guard assembly (4), nozzle tip, and

gasket (3).

3. Submerge nozzle tip in solvent to remove dried

material.

4. Blow air through nozzle tip to clean.

5. Airless spray nozzle tips are made of tungsten

carbide and are very brittle. Do not drop. To

clean a nozzle tip, use solvent, toothpick or

sharpened match. Never use a metal probe.

TO REPLACE WIRE ASSEMBLY:

1. BEFORE proceeding with any maintenance,

read safety procedure, paragraph 3, in High

Pressure Warning, page 1.

2. For convenience, you may wish to remove spray

gun from gun mount.

3. Carefully remove the cap (10). The spring (13)

is under tension and will come out when cap

(10) is removed.

4. Remove nut (14) and lockwasher (15). The back

plate (12), diaphragm (11) and washer (17)

may be removed at this time.

5. Loosen the wire assembly nut (6) from the stem

(20).

6. Loosen and remove the bearing screw assembly

(19) and the stem (20) from spray gun. The

packing (18) should also be inspected at this

time. If worn, replace.

7. Loosen and remove the gland nut (21). The

wire assembly (6) may now be pulled rearward

from the spray gun.

8. If worn, replace the gland set (22).

9. The material body assembly (7) may be

removed for cleaning by loosening set screws

(1). Note the pin in gun body assembly (8).

10. Reassemble in reverse order.

DIFFUSER ASSEMBLIES

Reduces fluid velocity to minimize tip wear and to

aid fluid filtration. Order 54-2229 Nylon Gasket

with either set-up, described below.

54-1639 thimble and 54-1797 (100 mesh) screen.

54-2378 Nut for use with 54-1835 (.005) 125 mesh

or 54-1836 (.009) 60 mesh edge type filter.

54-1797

54-1639

54-2378

54-1835

54-1836

CORRECT PATTERN

EN

77-2120-R16 (9/2018)

4 / 8

www.carlisleft.com