EN

77-1153-R25.1 (8/2014)

8 / 12

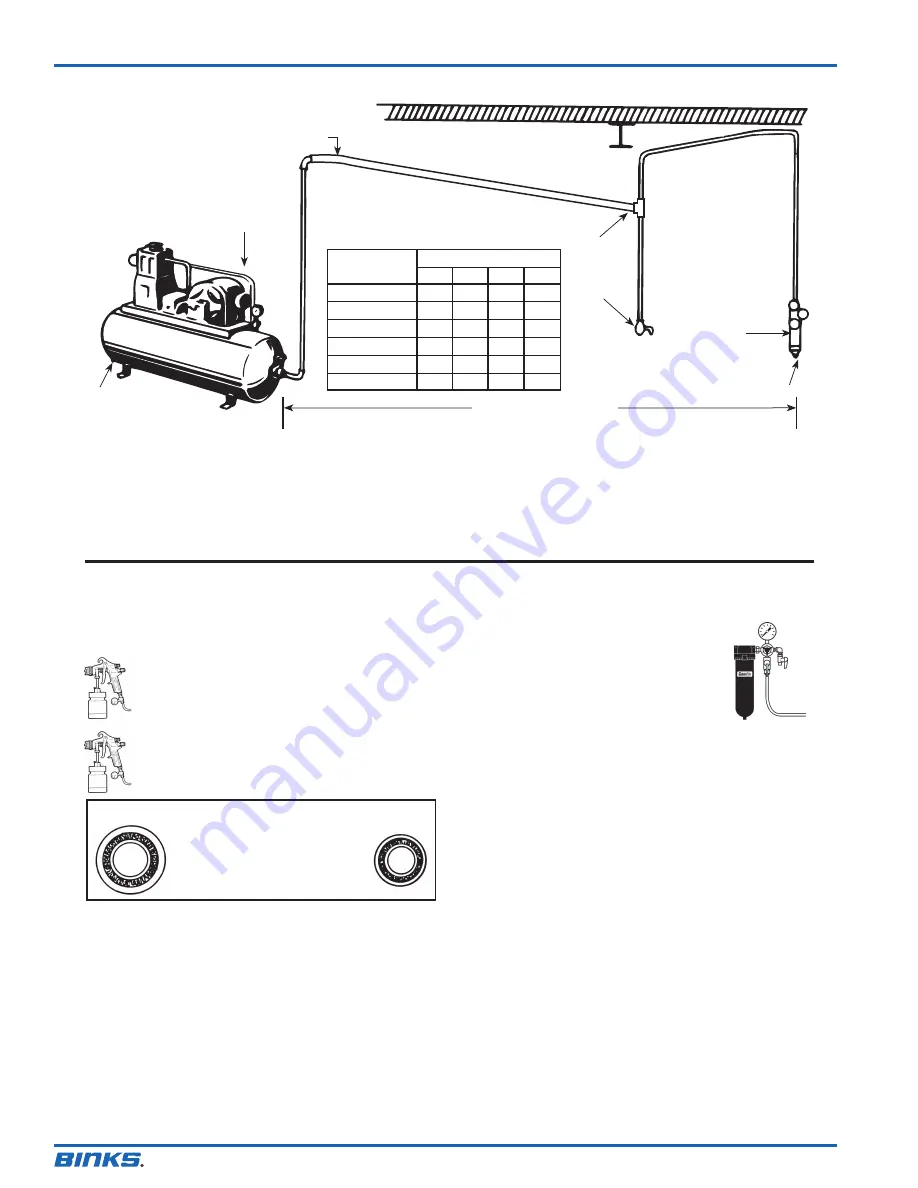

Length of Pipe (feet)

Air Flow

CFM

50 100 150 200

10

1/2” 3/4” 3/4”

20

3/4” 3/4” 3/4” 3/4”

30

3/4” 3/4” 1” 1”

40

1” 1” 1” 1”

50

1” 1” 1” 1”

70

1”

1” 1-1/4” 1-1/4”

AIR SUPPLY

The Clean Air™ filter should not be mounted on or

near the air compressor.

The temperature of air is greatly increased during compression. As the

air cools down to room temperature, in the air line, on its way to the

spray gun, the moisture contained in it condenses. Thus, for maximum

effectiveness, the oil and water extractor should be mounted at some

point in the air supply system where the temperature of the

compressed air in the line is likely to be lowest.

Air lines must be properly drained.

Pitch all air lines away from the compressor so that condensed moisture

can be drained off. Each low point in an air line acts as a water trap. Such

points should be fitted with an easily accessible drain. See diagram above.

PIPE SIZE, I.D. (inches)

Install

drain

at each

low point

Compressor unit

Drain

Pitch pipe away from air receiver

Oil and

water

extractor

Drain

25 FEET OR MORE

Oil and Water Extractor should be at least 25 ft. from the compressor. Further if possible.

Air pressure at the gun is important.

Atomizing pressure must be set to allow for the drop in air pressure

between the regulator and the spray gun.

A DeVilbiss Clean Air™ filter is important.

A Clean Air™ filter serves a double purpose. It

eliminates blistering and spotting by keeping air

free from oil and water... and its precision air

regulator makes possible perfect air pressure

control at the gun.

The best spray gun in the world will not operate

efficiently without a good compressor and a

Clean Air™ filter. Model HFRL-508 is recommended.

If you are attempting to get a fine finish without the use of a Clean Air™

filter you will not succeed.

Cross section view showing

comparison of inside hose

diameters (actual size).

60 lbs. regulated pressure

5/16”

1/4”

Only 44 PSI

25 feet of 1/4” I.D. hose causes a drop of 16 PSI

between the air supply and the gun.

Only 55 PSI

25 feet of 5/16” I.D. hose has a drop of only 5 PSI.

For this reason we recommend the use of 5/16” hose.

AIR PRESSURE