EN

77-2625-R13.1 (8/2014)

1 / 12

SERVICE MANUAL

BINKS MODEL 95

SPRAY GUN

6121-XXXX-X

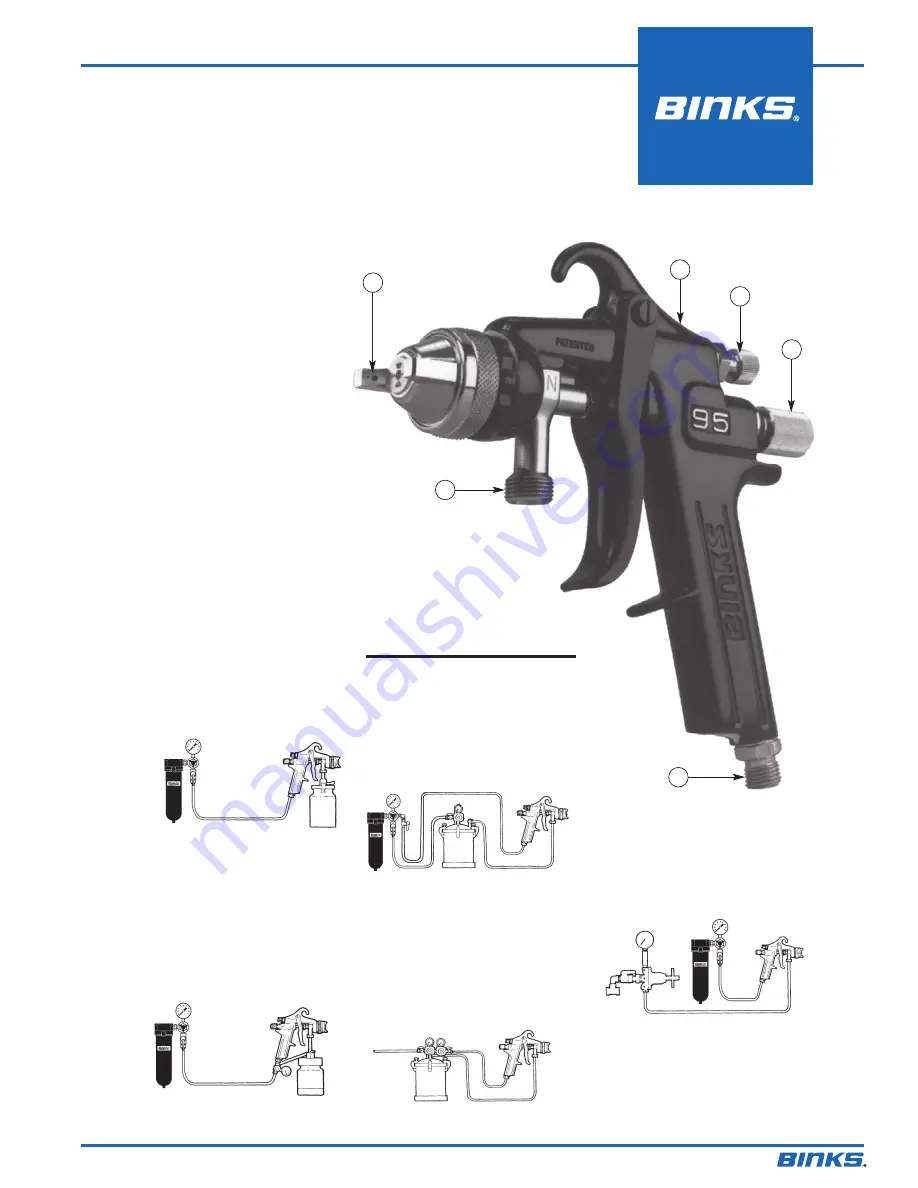

Model 95 Signature Series

Spray Gun

This handheld gun is the premier spray

gun in the Binks line. A combination

of the three best industrial spray guns,

Model 95 sets a new standard.

The Model 95 is a high production

gun with stainless steel fluid passages

which may be used with most coat-

ings. This new gun replaces Models

18, 62 and BBR spray guns, incorpo-

rating the best features of all three:

drop-forged anodized alumninum

body, stainless steel fluid passages,

adjustable floating needle valve, stain-

less steel or tungsten carbide fluid

nozzle, plated drop-forged brass self-

centering air nozzle, brass air valve

cartridge, adjustable spray pattern,

3/8" NPS(m) fluid inlet, 1/4" NPS(m)

air inlet. Weight 1 lb., 11 oz.

Illustration Key

1. Air Nozzle Assembly

2. Gun Body

3. Side Port Controls

4. Fluid Control Knob

5. Air Connection 1/4" NPS(m)

6. Fluid Connection 3/8" NPS(m)

1

3

2

4

5

6

PRESSURE FEED TANK HOOKUP

For medium production spraying (sin -

gle regulator).

Air pressure for atomi zation is regulated

at extractor, fluid pressure at tank regulator

(see figure 3).

PRESSURE FEED TANK HOOKUP

For portable painting operations

(double regulator).

Air pressure for atomization and fluid

supply is regulated by two individual air

regulators on tank (see figure 4).

TYPES OF INSTALLATION

SIPHON FEED CUP HOOKUP

Air pressure for atomization is regulated at

extractor. The amount of fluid is adjusted by

fluid control screw on gun, viscosity of paint,

and air pressure (see figure 1).

PRESSURE FEED CUP HOOKUP

For fine finishing with limited spraying.

Air pressure for atomization is regulated at

extractor; fluid pressure at cup regulator. For

heavy fluids and internal mix nozzle spray-

ing, fluid adjusted by control screw on gun.

Pressure cup also available less regulator

(see figure 2).

Extractor

Figure 1

Air

Siphon Cup

Extractor

Figure 5

Air

Fluid

Fluid

Regulator

Fluid

Figure 4

Air

Supply

Air Supply

Extractor

Air

Inlet

Figure 3

Air

Fluid

Outlet

Pressure

Tank

Pressure

Tank

Fluid

Oil & Water

Extractor

Cup

Regulator

Figure 2

Air

Fluid

Pressure Cup

PRESSURE FEED CIRCULATING

HOOKUP

For heavy production spraying.

Air pressure atomization regulated at

extractor. Fluid pressure regulated at fluid

regulator (see figure 5).