EN

77-2625-R13.1 (8/2014)

3 / 12

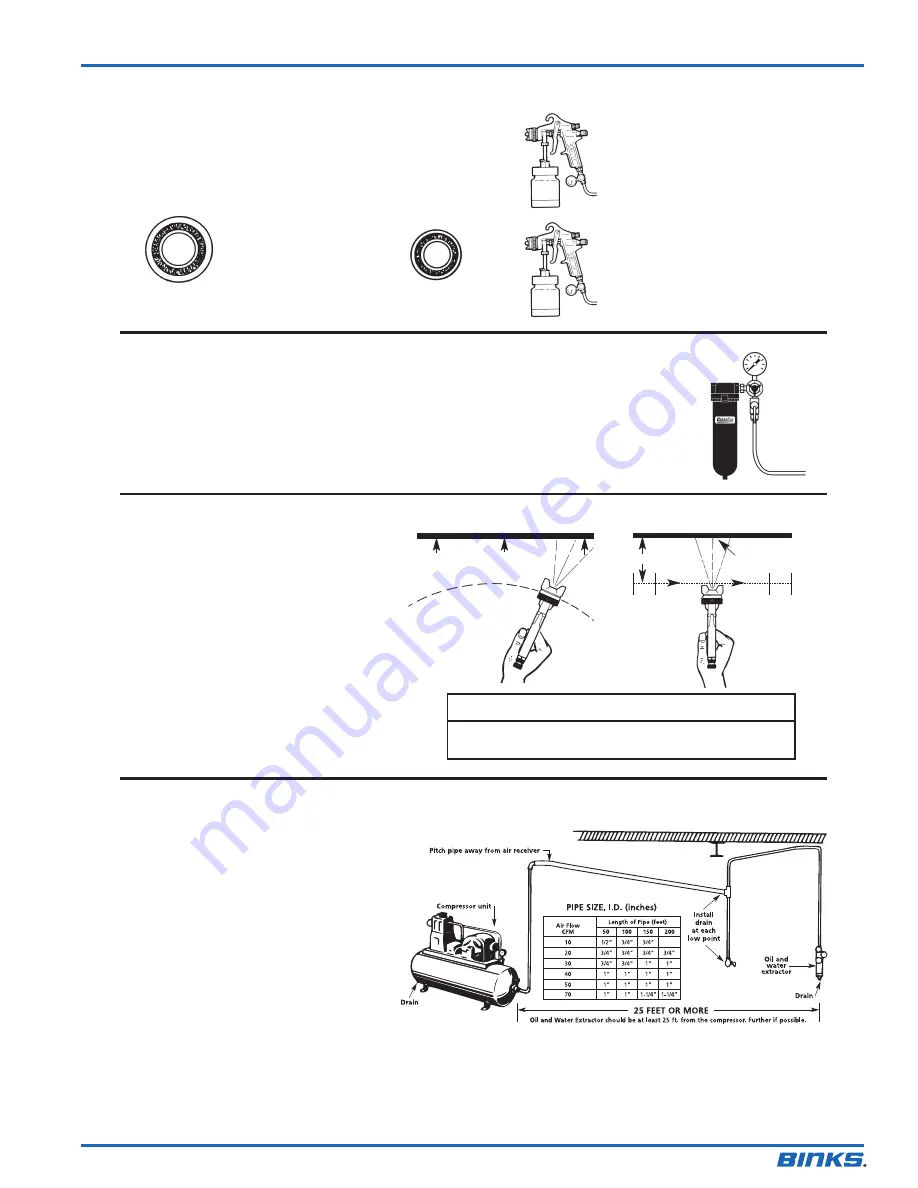

The first requirement for a good resultant finish is

the proper handling of the gun. The gun should be

held perpendicular to the surface being covered and

moved parallel with it. The stroke should be started

before the trigger is pulled and the trigger should

be released before the stroke is ended. This gives

accurate control of the gun and material.

The distance between gun and surface should be 6

to 12 inches depending on material and atomizing

pressure. The material deposited should always be

even and wet. Lap each stroke over the preceding

stroke to obtain a uniform finish.

NOTE

To reduce overspray and obtain maximum efficiency, always

spray with the lowest possible atomizing air pressure.

Coating should be even

and wet when spraying

Coating will

be light at

this point

Coating will

be heavy

at this point

Start

stroke

Pull

trigger

Release

trigger

End of

stroke

RIGHT

WRONG

TRAVEL OF GUN

6 to 12 inches

AIR PRESSURE

GUN HANDLING

BINKS OIL AND WATER EXTRACTOR IS IMPORTANT

5/16”

1/4”

Only 34 PSI at gun inlet

25 feet of 1/4” I.D. hose causes a drop of

26 PSI between the air supply and the gun.

(NOT RECOMMENDED)

48 PSI at gun inlet

25 feet of 5/16” I.D. hose causes a drop of

12 PSI between the air supply and the gun.

For this reason Binks recommends the use

of 5/16” hose.

(RECOMMENDED)

With 60 psi applied at air supply

Atomizing pressure must be set properly to allow for the drop

in air pressure between the regulator and the spray gun.

Achieving a fine spray finish without the use of a

good oil and water extractor is virtually impossible.

A Binks regulator / extractor serves a double pur-

pose. It eliminates blistering and spotting by keep-

ing air free of oil and water, and it gives precise air

pressure control at the gun.

Binks recommends using Model HFRL-508 Oil and

Water Extractor / Regulator. See your local distributor

for other models.

Cross section view

showing comparison of inside

hose diameters (actual size).

60 lbs. regulated pressure

It is extremely poor practice to mount the oil and

water extractor on or even near the compressor unit.

The temperature of the air is greatly increased as it

passes through the compressor and this compressed

air must be cooled before the moisture in it will con-

dense. If the air from the compressor is still warm

when it passes through the oil and water extractor,

moisture will not be effectively removed, but will

remain in suspension. Then, when the air cools in

the hose beyond the extractor, the moisture will

condense into drops of water and cause trouble.

Air lines must be properly drained

Pitch all air lines back towards the compressor so

that condensed moisture will flow back into the air

receiver where it can be removed by opening a

drain. Every low point on an air line acts as a water

trap. Such points should be fitted with an easily

accessible drain. See diagram.

AIR SUPPLY