EN

77-2625-R13.1 (8/2014)

4 / 12

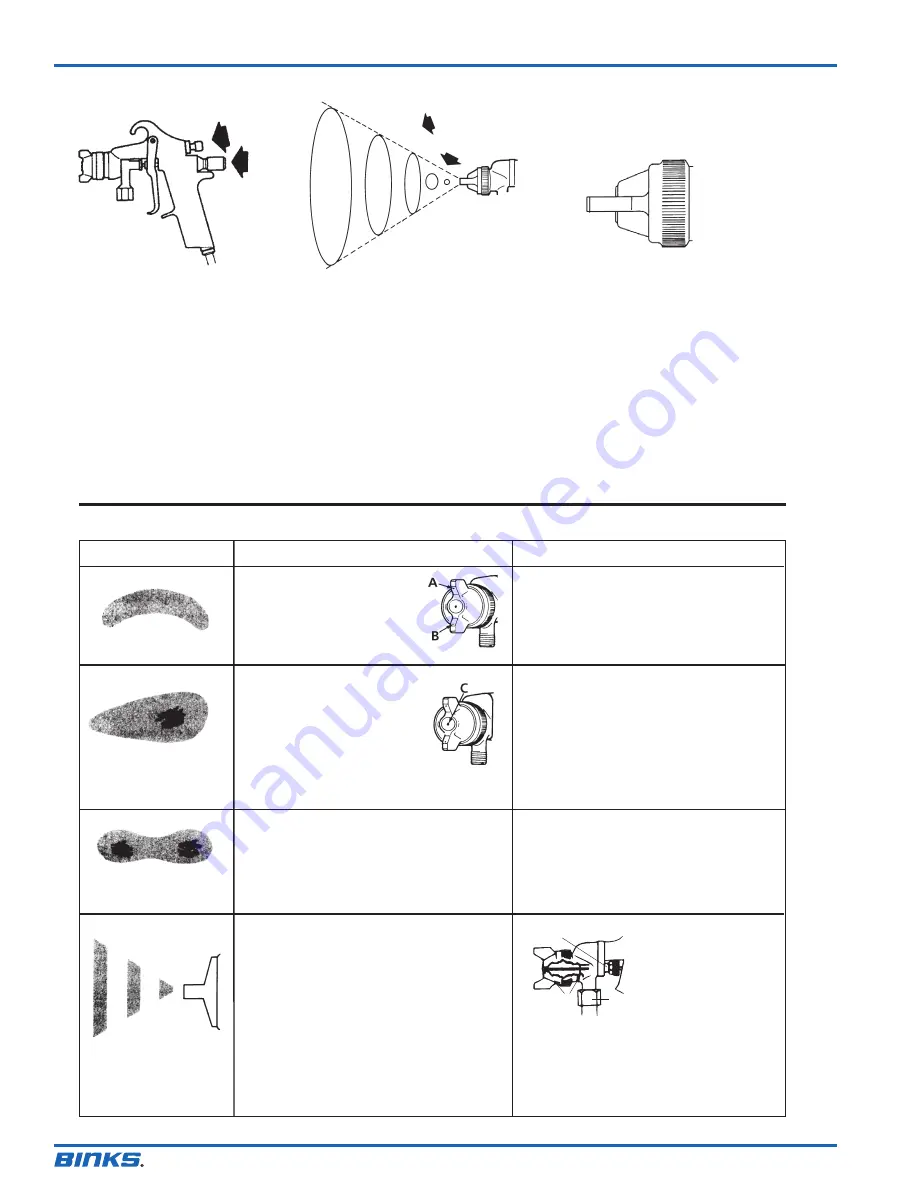

In normal operation, the wings on

the nozzle are horizontal as illus-

trated here. This provides

a vertical fan shaped pattern which

gives maxi-

mum coverage

as the gun is

moved back

and forth par-

allel to the

surface being

finished.

Spray width adjustment: Turn clock-

wise for round, counterclockwise for fan.

Fluid control screw: Turn clockwise to

decrease flow, counterclockwise to

increase flow.

As width of spray is increased, more

material must be allowed to pass through

the gun to obtain the same coverage on

the increased area.

SIPHON SPRAYING

Set atomization pressure at approximate-

ly 50 PSI for lacquer and 60 PSI for

enamel. Test spray. If the spray is too

fine, reduce the air pressure or open fluid

control screw. If the spray is too coarse,

close the fluid control screw. Adjust the

pattern width and repeat adjustment of

spray if necessary.

PRESSURE SPRAYING

After selecting correct size fluid orifice,

set fluid pressure for desired flow. Open

atomization air and test spray. If spray is

too fine, reduce air pressure. If spray is

too coarse, raise air pressure. Adjust pat-

tern width and repeat adjustment of spray.

Keeping fluid control screw in open posi-

tion will reduce fluid needle wear.

The spray pattern of

the Binks gun is variable

from round to flat with

all patterns in between.

Spray width

adjustment

Fluid

control

screw

FAULTY PATTERNS AND HOW TO CORRECT THEM

PATTERN

CAUSE

CORRECTION

Dried material around the

outside of the fluid nozzle tip

at position “C” restricts the

passage of atomizing air at

one point through the center

opening of air nozzle and

results in pattern shown.

This pattern can also be caused

by a loose air nozzle.

Dried material in side-port

“A” restricts passage of air.

Greater flow of air from

cleaner side-port “B” forces

fan pattern in direction of

clogged side.

Dissolve material in side-ports with thinner,

then blow gun clean. Do not poke into

openings with metal instruments.

Remove air nozzle and wipe off fluid tip

using rag wet with thinner. Tighten air

nozzle.

A split spray or one that is heavy on each

end of a fan pattern and weak in the mid-

dle is usually caused by:

(1) Too high an atomization air pressure

(2) Attempting to get too wide a spray pat-

tern with thin material.

Reducing air pressure will correct cause (1).

To correct cause (2), open material control

to full position by turning to left. At the

same time, turn spray width adjustment to

right. This will reduce width of spray, but

will correct split spray pattern.

(1) Dried out packing around material nee-

dle valve permits air to get into fluid

passageway. This results in spitting.

(2) Dirt between fluid nozzle seat and

body or loosely installed fluid nozzle

will make gun spit.

(3) A loose or defective swivel nut on

siphon cup or material hose can cause

spitting.

To correct cause (1) back

up knurled nut (E), place

two drops of machine oil

on packing, replace nut

and tighten with fingers

only. In aggravated cases,

replace packing.

To correct cause (2), remove fluid nozzle (F),

clean back of nozzle and nozzle seat in gun

body using rag wet with thinner, replace

nozzle and draw up tightly against body.

To correct cause (3), tighten or replace

swivel nut.

E

F

G