EN

77-2625-R13.1 (8/2014)

8 / 12

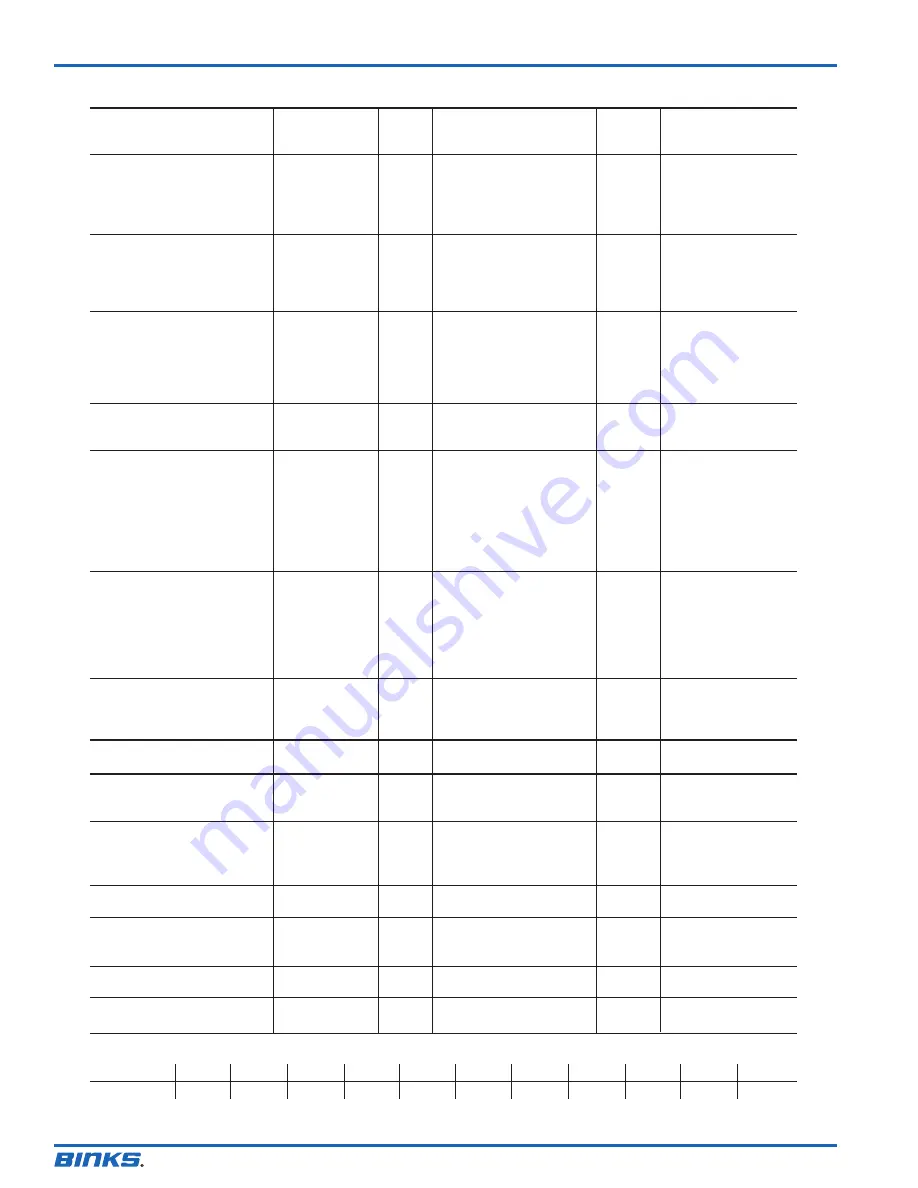

Nozzle No.

59ASS

59BSS

59CSS

63SS

63ASS

63BSS

63CSS

65SS

66SS

67SS

68SS

Orifice Size

.171

.218

.281

.028

.040

.046

.052

.059

.070

.086

.110

NOZZLE and NEEDLE SELECTION CHARTS

VERY THIN

63ss x 63P

PE

4.5

7.5

10.0

5

663

14-16 secs. Zahn 2 Cup

63Bss x 63PB

PE

9.0

14.3

20.0

14

663A

Wash primers, dyes,

66ss x 66SD

SE

7.9

12.1

—

10.5

665

stains, solvents,

66ss x 66SK

SE

11.0

15.2

19.5

13

665

water, inks

63Bss x 200

PI

3.1

5.2

6.4

12

663A

THIN

63Ass x 63P

PE

5.1

8.37

12.2

11

663A

16-20 secs. Zahn 2 Cup

63Bss x 63PE

PE

9.5

15.0

20.0

13

663A

Sealer, lacquers, primers,

66ss x 66SK

SE

11.0

15.2

19.5

13

665

inks, lubricants,

63Bss x 200

PI

3.1

5.2

6.4

12

663A

zinc chromates, acrylics

MEDIUM

63Bss x 63PB

PE

9.0

14.3

20.0

14

663A

19-30 secs. Zahn 2 Cup

63Css x 63PE

PE

9.5

15.0

20.0

13

663A

Synthetic enamels, varnishes, 66ss x 66SD

SE

7.9

12.1

—

11

665

shellacs, fillers, primers,

66ss x 66SK

SE

11.0

15.2

19.5

13

665

epoxies, urethanes, lubricants, 63Css x 200

PI

3.1

5.2

6.4

12

663A

wax emulsions, enamels

HEAVY

67ss x 67PB

PE

9.5

14.9

19.5

12

667

(Cream-like)

68ss x 68PB

PE

9.5

14.1

19.1

12

668

Over 28 secs. No. 4 Ford Cup

67ss x 206

PI

6.0

9.5

13.0

15

667

VERY HEAVY

68ss x 68PB

PE

9.5

14.1

19.1

12

668

Texture coatings,

68ss x 206

PI

6.2

9.8

13.2

15

668

Road marking paint

59Ass x 244

PI

7.8

11.5

15.2

12

659

59Ass x 245

PI

7.8

11.5

15.2

6

659

59Bss x 251

PI

7.8

11.5

15.2

12

659

59Bss x 252

PI

7.8

11.5

15.2

6

659

59Css x 262

PI

7.3

11.0

14.7

6

659

68ss x 206

PI

6.2

9.8

13.2

15

668

ADHESIVES

63Bss x 66SD-3

PE

7.9

12.1

16.2

4

663

Waterbase white vinyl glues

67ss x 67PB

PE

9.5

14.1

19.1

12

667

Solvent base, neoprenes

66ss x 66SD-3

PE

7.9

12.1

16.2

10

665

(contact cement)

66ss x 66SDJG

PE

10.4

—

—

8-9

665

66ss x 66R

PE/SE

—

4.2

—

RD

665

L6SS x 66SD-3

PE

9.5

14.2

19.0

10

665

L3BSS x 66SD-3

PE

9.5

14.2

19.0

10

663A

CERAMICS

67VT x 67PD

PE

10.0

15.0

20.0

15

667VT

Similar abrasive materials,

68VT x 68PB

PE

9.5

14.1

19.1

12

668VT

glazes, engobes,

porcelain enamel

BUFFING COMPOUNDS

64VT x 64PA

PE

12.1

15.0

21.0

13

664VT

67VT x 67PD

PE

10.0

15.0

20.0

15

667VT

CONCRETE CURING

66ss x 200

PI

3.1

5.2

6.4

15

665

COMPOUNDS

67ss x 206

PI

6.0

9.5

13.0

18

667

68ss x 206

PI

6.2

9.8

13.2

20

668

MULTICOLOR PAINTS

66ss x 200

PI

3.1

5.2

—

12

665

67ss x 206

PI

6.0

9.5

—

15

667

66ss x R3

PI

—

4.2

—

FAN

665

66ss x R8

PI

—

4.2

—

FAN

665

PTFE

63Ass x 63PB

PE

9.0

14.3

20.1

10

663A

66ss x 66SD

PE

7.9

12.1

—

7

665

HAMMERS

63ss X 63PB

PE

9.0

14.3

—

14

663A

66ss X 63PB

PE

9.0

14.3

—

14

665

66ss X 66SD

PE

7.9

12.1

—

7

665

WRINKLE ENAMELS

63Css x 63PB

PE

9.0

14.3

20.0

10

663A

66ss x 63PB

PE

9.0

14.3

20.0

10

665

ZINC RICH COATINGS

66ss x 67PD

PE

12.0

18.0

24.0

15

665N

67VT x 67PB

PE

9.5

14.1

19.1

12

667VT

Note: PE - Pressure External SP - Siphon External PI - Pressure Internal

TYPE OF FLUID

FLUID

NOZZLE

CFM AT

MAX

FLUID NEEDLE NOS.

TO BE SPRAYED

X AIR

TYPE

30

50

70

PATTERN

FOR SPRAY GUN

NOZZLES

PSI

PSI

PSI

AT 8"

MODEL 95