5

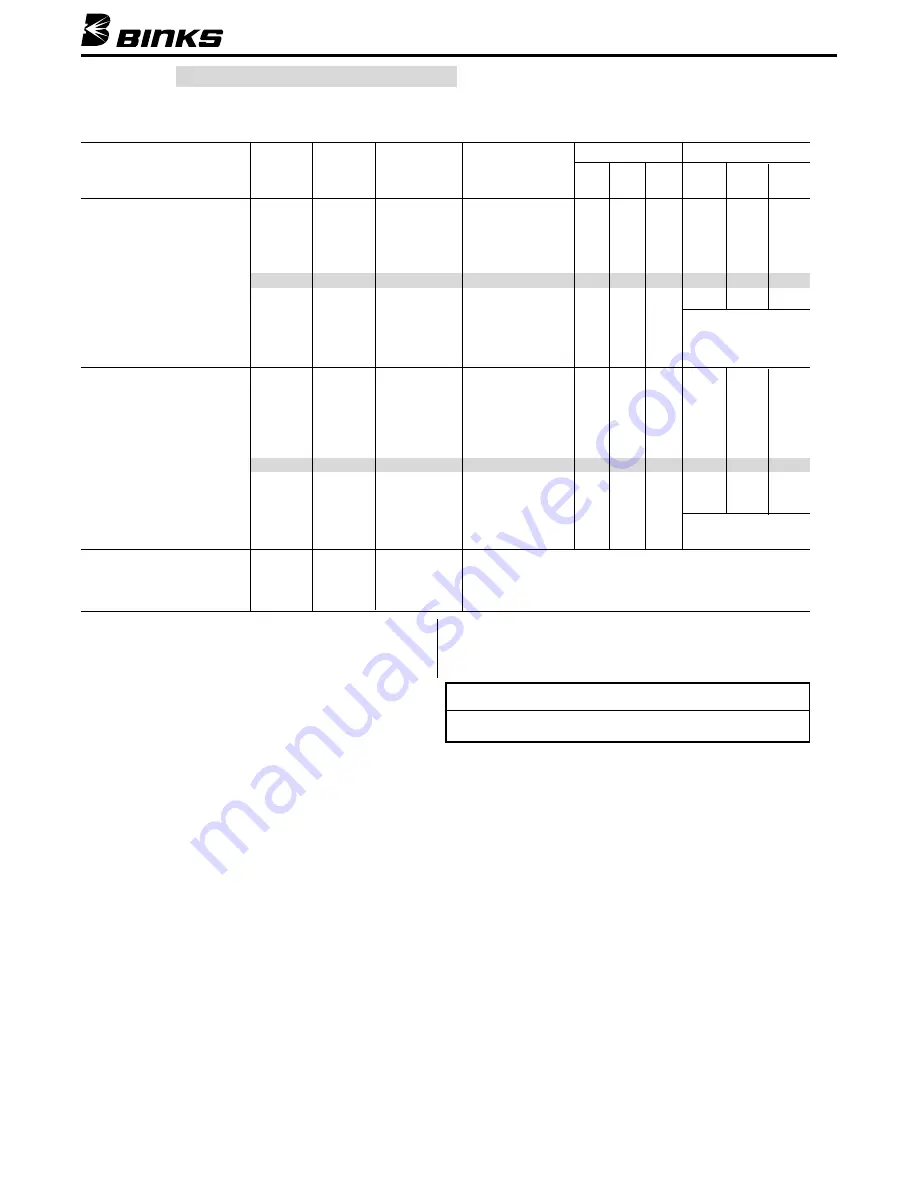

NOZZLE AND NEEDLE SELECTION CHART

FOR MODEL 95G GRAVITY FEED SPRAY GUNS

Type of Fluids

Fluid

▲

Air

Fluid

Max. Pattern

CFM

Fluid Flow*

Nozzle

Nozzle

Needle

at 8"

20

30

40

20

30

40

Distance

Low to Medium

Viscosity Fluids

(14-20 second-No. 2 Zahn)

Dyes, Stains, Lacquers,

65SS

66SD

865

11" @ 40 PSI

7.5

10.5 13.0

168

209

226

Primers, Waterborne

•66SS

66SD

865

15" @ 40 PSI

7.5

10.0 12.0

244

290

350

Coats, Base Coat

66SS

66SK

865

15.5" @ 40 PSI

9.0

11.0 13.5

235

293

367

Metallics

L6SS

66SD

865

15" @ 40 PSI

7.5

10.5 13.0

VARIES

L6SS

66SK

865

15.5" @ 40 PSI

9.0

11.0 13.5

WITH

VISCOSITIES

Medium to High

Viscosity Fluids

(19-30 second-No. 2 Zahn/

Over 28 sec.-No. 4 Ford)

Urethanes, Fillers,

65SS

66SD

865

11.5" @ 40 PSI

7.5

10.5 13.0

176

223

263

Epoxies, Varnishes,

•66SS

66SD

865

12" @ 40 PSI

7.5

10.0 12.0

205

244

275

Lubricants, Shellacs,

66SS

66SK

865

15" @ 40 PSI

9.0

11.0 13.5

230

302

369

Fillers Waterborne,

67SS

67SK

867

18" @ 40 PSI

9.0

11.5 14.0

348

453

504

Top Coats

L6SS

66SD

865

12" @ 40 PSI

7.5

10.5 13.0

VARIES WITH

L6SS

66SK

865

15" @ 40 PSI

9.0

11.0 13.5

VISCOSITY

Vitreous Enamels

(20-30 second-No. 2 Zahn)

67VT

67SK

867VT

VARIES WITH

Ceramics, Glazes

68VT

68SA

868VT

FLUID VISCOSITIES

▲

Fluid Nozzle Reference Chart

Nozzle No.

65SS

66SS

67SS

68SS

Orifice Size

.059

.070

.086

.110

Tungsten Carbide Fluid Nozzle & Fluid Needle Tip

L-Series Fluid Nozzles tend to minimize “smoking effect” at the

air cap allowing for less fluid build-up at the air nozzle horns.

Typically, they require slightly higher air pressures to achieve

the same fluid delivery as standard No. 60 Series nozzles.

*Fluid flow in cc/minute. Divide above fluid flow by

29.6 to convert to fluid ounces (U.S.)

NOTE

Pressure feed type air nozzles are not recommended to be

used with Model 95G Gravity Feed Spray Gun.

STANDARD SET-UP 66SS X 66SD• – ALL OTHERS ARE OPTIONAL