Your Binks 95SL Gun is exceptionally

rugged in construction and built to stand

up under hard, continuous use. However,

like any other precision instrument, your

gun’s most efficient operation depends on

a knowledge of its construction, operation

and maintenance. Properly handled and

cared for, it will produce beautiful,

uniform finishes long after other spray

guns are worn out.

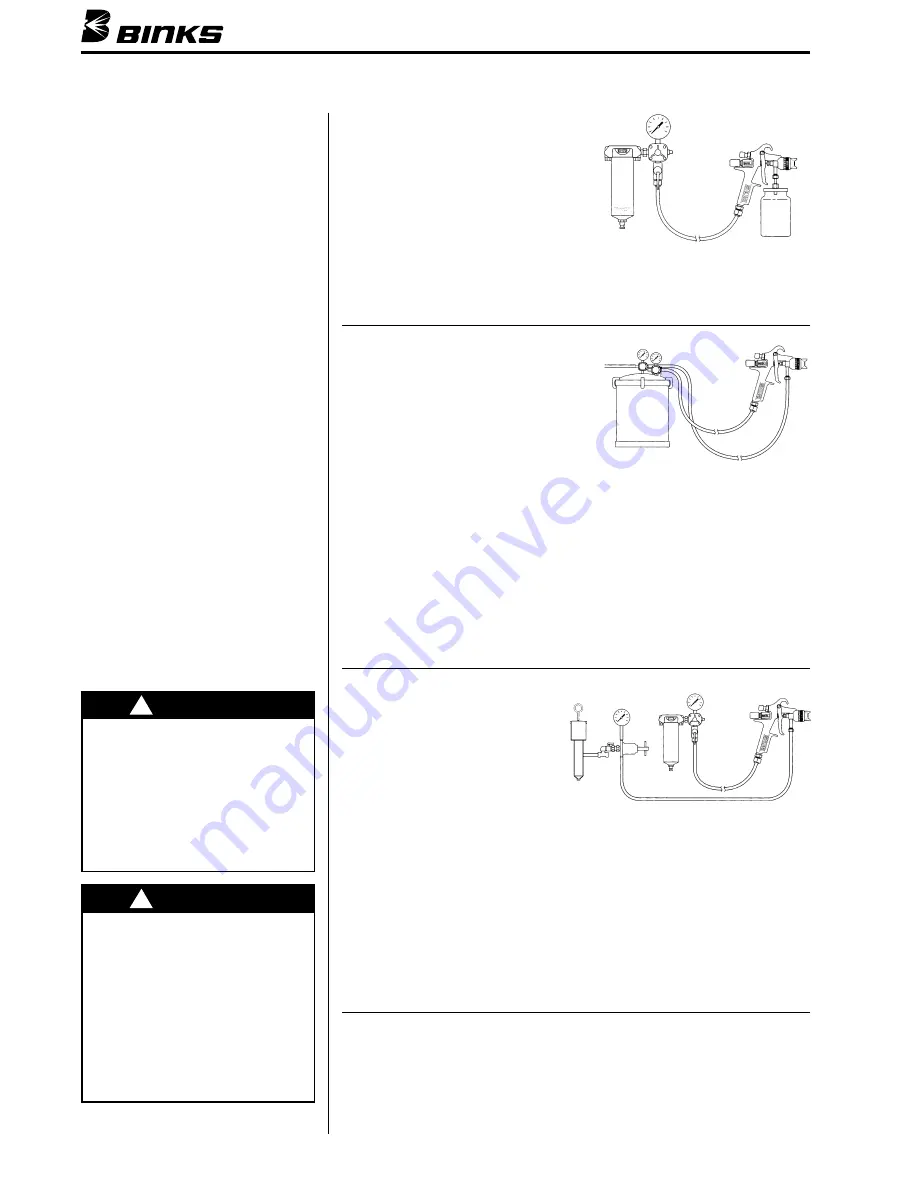

The 95SL Gun can be used in any of

three modes:

• Siphon Feed Cup Hook-Up

• Pressure Feed Pump Hook-Up

• Pressure Feed Tank Hook-Up

The siphon mode uses a lowered air

pressure in the gun to draw fluid from

the cup into the gun. Instructions for

assembling the gun with the siphon cup

are included in this Part Sheet.

Pressure feed mode for tanks rely on systems

that separately regulate fluid and air flow.

Pressure feed circulating hook-ups are usually

connected to large circulating systems.

Such a system has separate, regulated fluid

and air flows. We recommend choosing a

smaller fluid nozzle if you are using either

of the pressure feed systems.

On this page are brief descriptions and

illustrations of the siphon feed, the

pressure feed tank hook-ups, and the

pressure feed pump hook-up.

2

HOW TO SET UP and OPERATE YOUR Binks Model 95SL SPRAY GUN

WARNING

FLUID FLOW

Regarding Paints, Solvents, and

Other Coatings Safety

Do not use open containers for storage

or disposal of paint, other coatings,

cloth, or paper used in preparation and

application. Many paints and coatings

contain volatile chemicals that are a

cause of pollution and are a health

and fire hazard. Always wear appro-

priate clothing, including gloves,

eye protection, and a respirator when

using the gun.

!

WARNING

CONNECTING TO AIR HOSE

Regarding Air Pressure Safety

Shut off air pressure before connecting

or disconnecting the air hose or before

removing any components from the gun.

For air supply, use a suitable length of

5/16" diameter air hose fitted with a

1/4" NPS(f) connector at the gun end.

For hose lengths over 50', use a 3/8"

diameter hose.

!

OIL AND WATER EXTRACTOR

Achieving a fine spray finish without the use of a good oil and water extractor is

almost impossible. A regulator/ extractor serves a double purpose. It eliminates

blistering and spotting by keeping air free of oil and water, and it gives precise

air pressure control. Set the atomizing pressure to allow for any drop in air pressure

between the regulator and the spray gun. We recommend the HFRL-508 Oil and

Water Extractor/Regulator for use with the 95SL gun.

SIPHON FEED (CUP) HOOK-UP

In this mode, air pressure for atomiza-

tion is regulated at the extractor.

The amount of fluid is adjusted by the

fluid control knob (20) on the gun,

viscosity of paint, and air pressure.

HOW TO SET UP YOUR GUN FOR SIPHON APPLICATIONS

1. Insert the fluid inlet (26) into the cup’s

swivel nut and tighten.

2. Connect air hose from air regulator

on the extractor to air connection

(21) on the gun.

PRESSURE FEED (TANK) HOOK-UP

For portable painting operations, use

a double-regulator pressure-feed tank

hook-up. In this mode, air pressure for

both atomization and fluid supply is

regulated by two separate air regulators

on the tank.

HOW TO SET UP YOUR GUN FOR PRESSURE FEED (TANK) HOOK-UP

1. Connect air hose from air regulator on

the tank to air connection (21) on the

gun. (If tank is equipped with only one

regulator, the air line must connect from

the regulator to the extractor.)

2. Connect the fluid hose from fluid

outlet on tank to the fluid inlet (26)

on the gun.

3. Fluid delivery is controlled by various

means:

• The first regulator on the tank,

which regulates air into the tank

(this creates the fluid pressure);

• The fluid control knob (20) on

the gun, which can be used to

fine tune fluid delivery;

• Other factors, which include fluid

orifice size, fluid hose length, hose

diameter and material viscosity.

PRESSURE FEED (PUMP) HOOK-UP

Use this mode for heavy production

spraying. In this mode, air pressure

for atomization is regulated at the

extractor. Fluid pressure is regulated

at the fluid regulator.

HOW TO SET UP YOUR GUN FOR PRESSURE FEED (PUMP) HOOK-UP

1. Connect air hose from air regulator to

air connection (21) on the gun.

2. Connect the fluid hose from fluid

regulator to the fluid inlet (26) on the

gun. If the system does not require a

fluid regulator, the hose connects to

the pump’s fluid outlet.

3. Fluid delivery is controlled by various

means:

• The air regulator on the pump, which

regulates air into the pump

(this creates the fluid pressure);

• A fluid regulator, which may be

utilized on the output of the pump;

• The fluid control knob (20) on

the gun, which can be used to

fine tune fluid delivery;

• Other factors, which include fluid

orifice size, fluid hose length, hose

diameter and material viscosity.