4

tRoUBLeSHootinG defectiVe SPRaY PatteRnS

The following procedure summarizes the steps that an

operator must immediately take when the first signs of a

defective spray pattern emerge.

1. Check the external portion of the fluid tip for material

buildup. If buildup has occurred, secure the gun trig-

ger safety switch and clean the gun fluid tip with a

non-metal soft brush.

2. If the spray pattern exhibits signs of tails at the top or

bottom ends of the pattern, increase the air pressure

gradually until the tails disappear.

3. If increasing air pressure does not dissipate the tails,

the fluid tip may be worn and may need to be

replaced. Another sign of the need to replace a worn

tip is a gradual decline in spraying pattern width.

4. If cleaning or replacing the fluid tip does not dissipate

the tails; the spraying defect is most likely due to the

material temperature and/or viscosity.

5. If pattern pulsation or blinking occurs, check the pres-

sure regulators, all downstream regulators, and the

pump. These may require further adjustment or even

repairs.

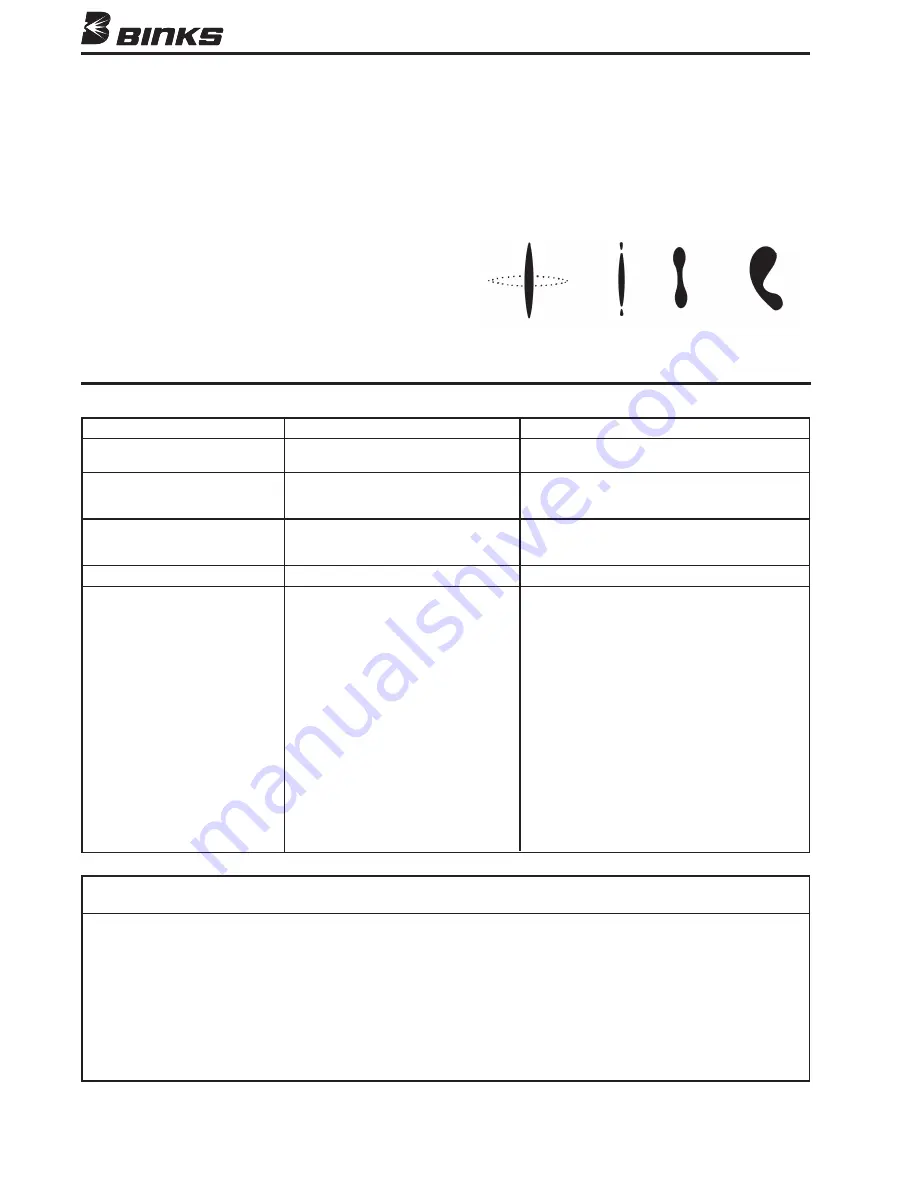

figure 3

Correct

Pattern

Tails

Hour

Glass

Distorted

Pattern

PRoBLeM

caUSe

action

fluid leaking from the back

Worn seal or needle shaft.

Replace needle packing cartridge (7).

of seal cartridge assembly (8)

fluid leaking from the front

Needle ball worn or damaged.

Replace needle packing cartridge (7).

of the gun

Worn seat assembly.

Replace fluid seat (3).

fluid in air passages

Spray tip seal leaking.

Tighten AA10 air cap assembly (1)

Replace carbide tip assembly (2).

Leaking around fluid seat.

Tighten or replace fluid seat (3).

Slow fluid shut off

Fluid buildup on cartridge assembly.

Clean or replace cartridge assembly (7).

no fluid output when triggered

Tip orifice plugged.

turn off fluid supply. Relieve pressure into a

closed-grounded container.

engage trigger safety.

Remove AA10 air cap assembly (1)

and the carbide tip (2).

Clean or replace carbide tip assembly (2).

Collet on needle has slipped.

turn off fluid supply. Relieve pressure into a

closed-grounded container.

Remove trigger (19). Remove needle packing

cartridge (7). Loosen collet and move until

the needle is flush with the rear of the collet.

Tighten collet.

Fluid filter or fluid hose plugged.

turn off fluid supply. Relieve pressure into a

closed-grounded container. turn off air supply

to pump and relieve fluid pressure with by

pass valve. engage trigger safety. Very slowly

loosen the hose connection at the gun to

relieve any pressure in hose.

Remove hose

and clear obstruction.

GeneRaL tRoUBLeSHootinG

iMPoRtant ReGULatoRY note

The AA-1500 Air-Assisted H.V.L.P. hand spray gun combines the proven efficiency of the Binks compliant spray guns with

air-assisted atomization to yield a reliable, carefully engineered compliant spray gun. With 25' of 5/16" I.D. air hose and

regulator set at only 20 p.s.i. the compliant air cap registers 10 p.s.i. of atomization air to shape and soften the spray pattern.

The AA-1500 air-assisted H.V.L.P. gun operates at high transfer efficiencies and fully complies with all government regulations

for H.V.L.P. spray guns.

Max. Fluid Input: 1500 p.s.i.

Max. static air pressure at regulator with 25' of hose to inlet: 20 p.s.i.

Max. Dynamic Gun Inlet Air Pressure: 15 p.s.i.

Gun Body: Forged Aluminum Alloy

Fluid Path: Stainless Steel and Tungsten Carbide