3

1. Connect your high-pressure airless fluid hose to the

gun fluid inlet and tighten securely.

2. Connect your air hose to the gun air connection and

tighten securely.

3. Set the fluid pressure at the gun’s lower end of the

pressure range. A typical starting fluid pressure is

1600 psi. Actual starting pressure points may be higher

or lower than 1600 psi and depend on the setup—

including the type of pump used, the type of material

sprayed, and the spray gun itself.

4. Using the control knob on the gun air regulator, set

the air pressure at zero.

5. To test the spraying pattern, spray a piece of wood or

cardboard with a fast pass about one foot away from

the piece. The results of the test will allow you to

determine the uniformity of the particle size and

spraying pattern.

6. If the spraying pattern develops tails or is not uniform,

gradually increase the air pressure as necessary to

develop a uniform spraying pattern. Typically, 10 psi

air pressure is adequate, since the air is used to shape

the patterns rather than for atomization of the coating.

7. If the quality of spray is acceptable, begin spraying.

If the spraying rate is too slow to keep up with the

production line speed, or if the quantity of material

sprayed is inadequate for acceptable coverage, gradu-

ally increase the fluid pressure in 50 psi increments

using the fluid regulator control knob. However, note

that as the fluid pressure increases, more air is needed

to eliminate the tails.

Consistency in spraying can be increased across spray

gun operators and similar spraying jobs by developing

pressure standardization charts. Repeat step 6 until the

required material coverage and spraying speed are

achieved. If the maximum fluid pressure is reached

before the required material coverage and spraying speed

are achieved, you may need to switch to a larger fluid tip.

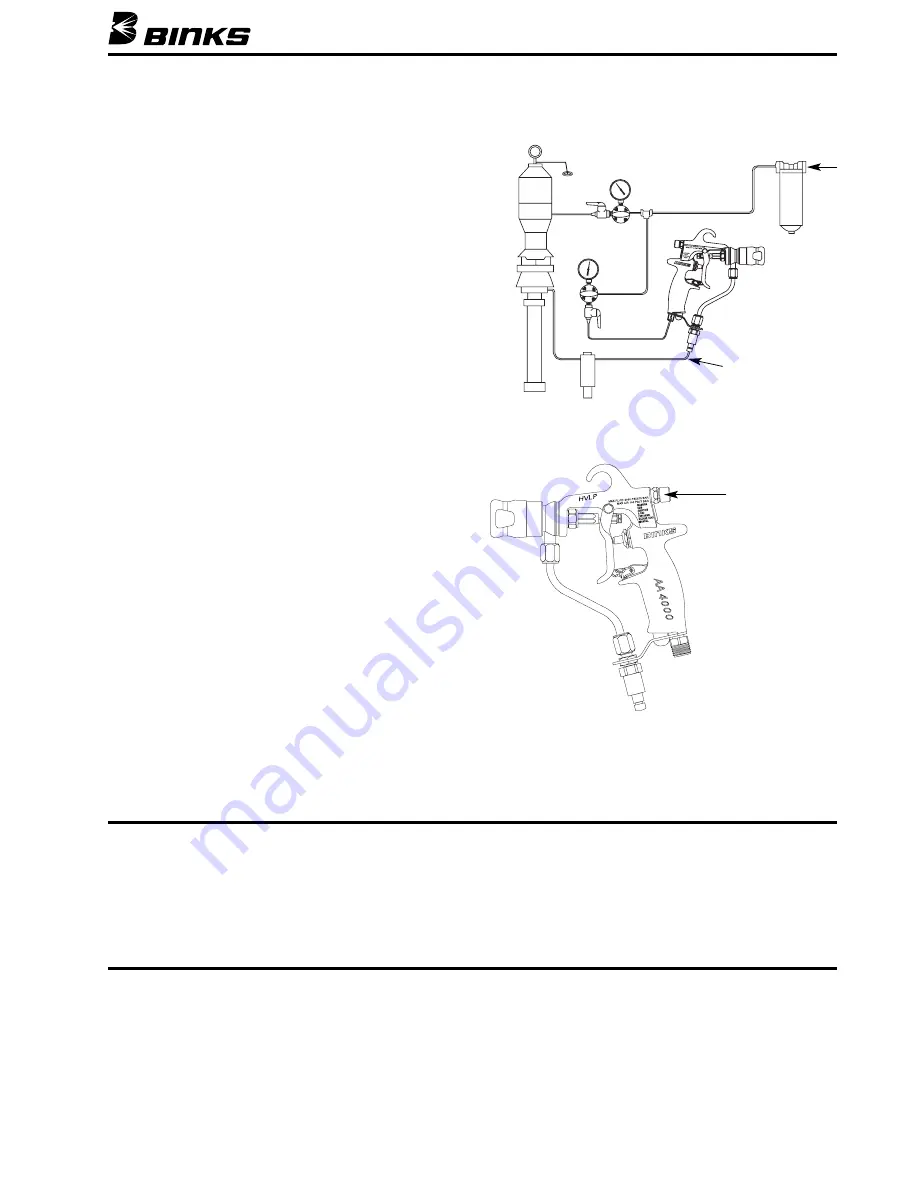

TYPICAL HOOK-UP

Fan pattern adjustment: turn knob counterclockwise to

increase pattern; clockwise to decrease pattern (Fig. 2).

SPRAY GUN SET-UP

Pump

Regulator

Grounding

Wire

Regulator

Air

Air

Air

Fluid

Fluid Filter

Gun

Oil and Water

Extractor

Figure 1

Fan Control

Knob

Figure 2

FLUID TIP SELECTION

Factors to consider in selecting a fluid tip for an air-

assisted airless spray gun include (1) the size of the parts

being sprayed; (2) the production line speed; (3) the

material flow rate and film thickness; (4) the viscosity of

the material applied; (5) the type of material applied; and

(6) the quality of atomization of the coating required.

The selection of a fluid tip necessary to perform a specif-

ic spraying job is best determined through a combination

of experimentation and expert advice from your material

and equipment suppliers.

FLUID HOSES

Air-assisted airless spray guns operate at fluid pressures

higher than operating pressures of air spray guns. As a

result, when operating an air-assisted airless spray gun, it

is critical to select the appropriate fluid hose that is rated

for the pressure range at which the airless gun is operated.

Air

In