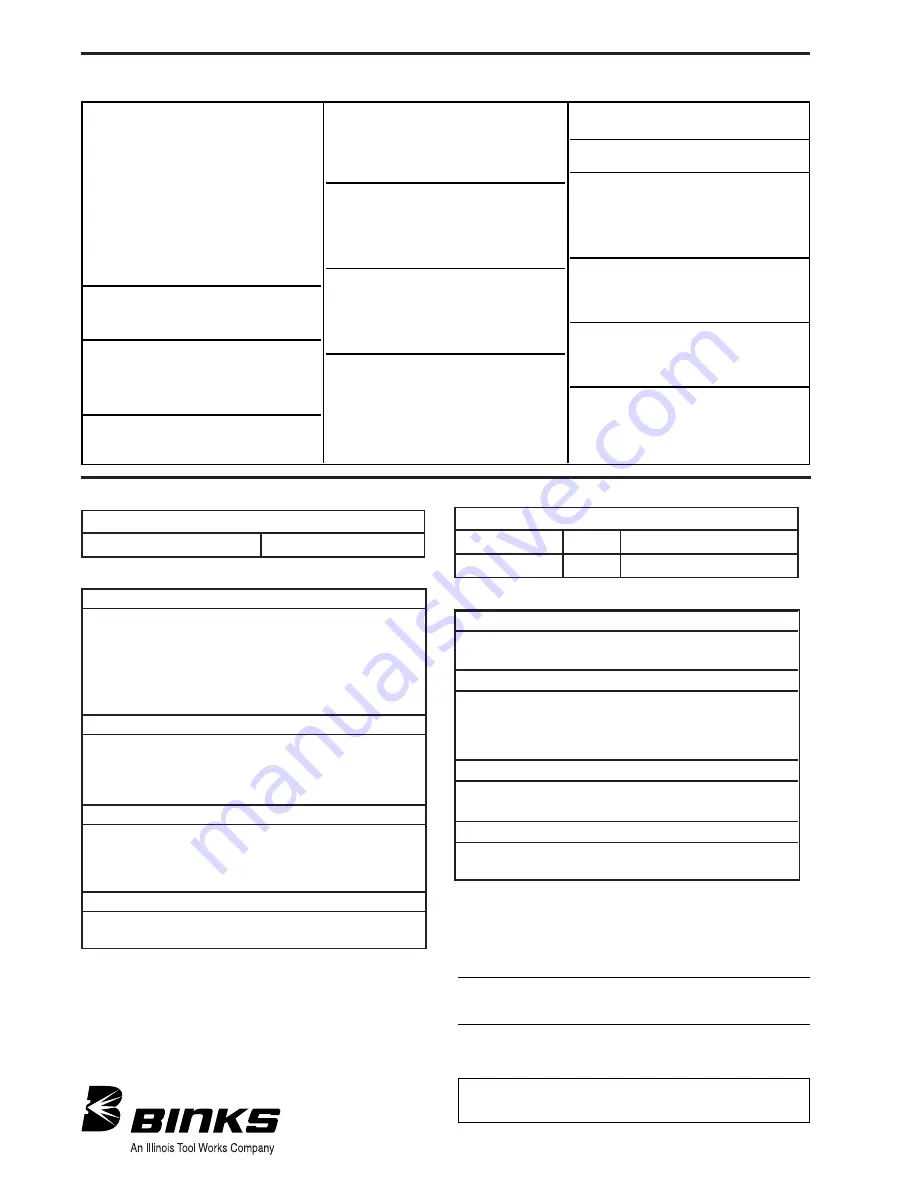

FLUID SEAT APPLICATION CHART

APPLICATION CHART

Carbide (Standard) .....54-4960

UHMW (Optional) ....54-4926

AIR CAP APPLICATION CHART

APPLICATION CHART

AA2 (Optional) 54-4980 Thin to Medium Materials

AA4 (Standard) 54-4978 Medium to Hvy. Materials

HOSES

71-4990

15' Polyurethane Air Tubing ASM w/fittings,

3/8" O.D., 1/4" I.D.

71-4991

25' Polyurethane Air Tubing ASM w/fittings,

3/8" O.D., 1/4" I.D.

71-8087

15' 3/16" High Pressure Fluid Hose Assembly

71-8088

25' 3/16" High Pressure Fluid Hose Assembly

FITTINGS

54-4975

1/8" NPT Male x 3/8" O.D. Push-In

Tube Fitting (optional)

54-4976

1/4" NPT Female x 3/8" O.D. Push-In

Tube Fitting (optional)

FLUID FILTERS

103-1241

100 Mesh Inline Filter, 4000 PSI working pressure

54-3655

100 Mesh (Element) Gun Mounted Filter, 5800 PSI w.p.

54-5010

100 Mesh (Screen) Gun Mounted Filter, 4000 PSI w.p.

54-4725

100 Mesh (Element) Gun Mounted Filter, 4000 PSI w.p.

REPLACEMENT FILTERS

54-1835

Replacement filters for 54-3655 and 54-4725

54-5012-K10

Replacement filter for 54-5010

ACCESSORIES

FLUID REGULATORS

845011

Less Gauge, 1000 to 3000 PSI regulated range

845013

Less Gauge, 2000 to 5000 PSI regulated range

CLEANING KIT

54-4994

Cleaning Kit: Includes one standard stiff

nylon pipe cleaning brush, full-size nylon

brush, tip cleaner and Binks

Gunners Mate

lubricant.

REPAIR KIT

54-4993

Replacement Parts Kit Items

(

Includes Items 4, 4A, 7, 8, 10 and 21)

TEST GAUGES

54-4997

H.V.L.P. Test Gauge AA2

54-5022

H.V.L.P. Test Gauge AA4

ACCESSORIES

(Cont.)

12/07 © 2007

Inc. All rights reserved. Printed in U.S.A.

Industrial Finishing

Binks has authorized distributors throughout the world. For technical

assistance or the distributor nearest you, see listing below.

U.S./Canada Technical Service Office:

195 Internationale Blvd., Glendale Heights, IL 60139

Toll-Free Telephone: 1-888-992-4657 (U.S.A. and Canada only)

Toll-Free Fax: 1-888-246-5732

Binks Worldwide Sales and Service Listing:

www.binks.com

WARRANTY

This product is covered by Binks’ 1 Year Limited Warranty.

77-2776R-9 Revisions:

(P2) Replaced warnings.

SPRAY TIP SELECTION CHARTS

FAN

PART NO.

SIZE

WIDTH

113-00702

.007

1"-2"

113-00704

.007

2"-4"

113-00706

.007

4"-6"

113-00708

.007

6"-8"

113-00902

.009

1"-2"

113-00904

.009

2"-4"

113-00906

.009

4"-6"

113-00908

.009

6"-8"

113-00910

.009

8"-10"

113-00912

.009

10"-12"

113-01104

.011

2"-4"

113-01106

.011

4"-6"

113-01108

.011

6"-8"

113-01110

.011

8"-10"

113-01112

.011

10"-12"

113-01114

.011

12"-14"

113-01304

.013

2"-4"

113-01306

.013

4"-6"

113-01308

.013

6"-8"

113-01310

.013

8"-10"

113-01312

.013

10"-12"

113-01314

.013

12"-14"

113-01316

.013

14"-16"

113-01506

.015

4"-6"

113-01508

.015

6"-8"

113-01510

.015

8"-10"

113-01512

.015

10"-12"

113-01514

.015

12"-14"

113-01516

.015

14"-16"

113-01518

.015

16"-18"

113-01706

.017

4"-6"

113-01708

.017

6"-8"

113-01710

.017

8"-10"

113-01712

.017

10"-12"

113-01714

.017

12"-14"

113-01716

.017

14"-16"

113-01718

.017

16"-18"

113-01806

.018

4"-6"

113-01808

.018

6"-8"

113-01906

.019

4"-6"

113-01908

.019

6"-8"

113-01910

.019

8"-10"

113-01912

.019

10"-12"

113-01914

.019

12"-14"

113-01916

.019

14"-16"

113-01918

.019

16"-18"

113-02110

.021

8"-10"

113-02112

.021

10"-12"

113-02114

.021

12"-14"

113-02116

.021

14"-16"

113-02118

.021

16"-18"

113-02410

.024

8"-10"

113-02412

.024

10"-12"

113-02414

.024

12"-14"

113-02416

.024

14"-16"

113-02418

.024

16"-18"

113-02710

.027

8"-10"

113-02712

.027

10"-12"

113-02714

.027

12"-14"

113-02716

.027

14"-16"

113-02718

.027

16"-18"

HOW TO ORDER THE AA 4000 AIR-

ASSISTED AIRLESS SPRAY GUN

4000-0000-4

(Standard AA4 Air Cap less Spray Tip)

(Optional AA2 Air Cap order separately)

Spray Tip must be ordered separately.

Use this chart to determine orifice size and

fan size required*.

*Note: Listed Fan Widths based on 1000 PSI with

water. Actual results may vary, depending on

material viscosity.

FAN

PART NO.

SIZE

WIDTH

FAN

PART NO.

SIZE

WIDTH