3

OPERATION and MAINTENANCE INSTRUCTIONS for M1-G HVLP SPRAY GUN

SPRAY GUN CLEANING INSTRUCTIONS

In certain states, spraying solvents which contain Volatile

Organic Compounds (VOC) into the atmosphere when

cleaning a spray gun is now prohibited.

In order to comply with these new air quality laws Binks

recommends one of the following two methods to clean

your spray finishing equipment:

1.

Spray solvent through the gun into a

closed system

.

An enclosed unit or spray gun cleaning station con-

denses solvent vapors back into liquid form which

prevents escape of VOC’s into the atmosphere.

2.

Place spray gun in a washer type cleaner. This

system must totally enclose the spray gun, cups, noz-

zles and other parts during washing, rinsing and

draining cycles. This type of unit must be able to

flush solvent through the gun without releasing any

VOC vapors into the atmosphere.

Additionally, open containers for storage or disposal

of solvent or solvent-containing cloth or paper used for

surface preparation and clean-up may not be used.

Containers shall be nonabsorbent.

CLEANING GUN AND GRAVITY FEED CUP

Remove the cup cover and drain unused material from

cup. Carefully rinse cup with solvent. Place clean solvent

into the cup and spray this through the gun until it is clean.

Remove and clean the cup if necessary. Blow air through

the gun to dry it. (Refer to Service Bulletin SBBI-4-043 for

cleaning instructions when using cup liners.)

Your new M1-G HVLP Spray Gun is exceptionally rugged

in construction and is built to stand up under hard, continu-

ous use. However, like any other fine precision instrument,

its most efficient operation depends on a knowledge of its

construction, operation and maintenance. Properly handled

and cared for, it will produce beautiful, uniform finishing

results long after other spray guns have worn out.

IMPORTANT:

Before removing any components from the

spray gun, shut off air pressure and drain material from the

paint cup.

SETUP FOR SPRAYING

CONNECTING GUN TO AIR HOSE

Air should be supplied by a suitable length of 5/16" diameter

air hose fitted with a 1/4 NPS(f) connection at gun end. For

hose lengths over 50', use 3/8" hose.

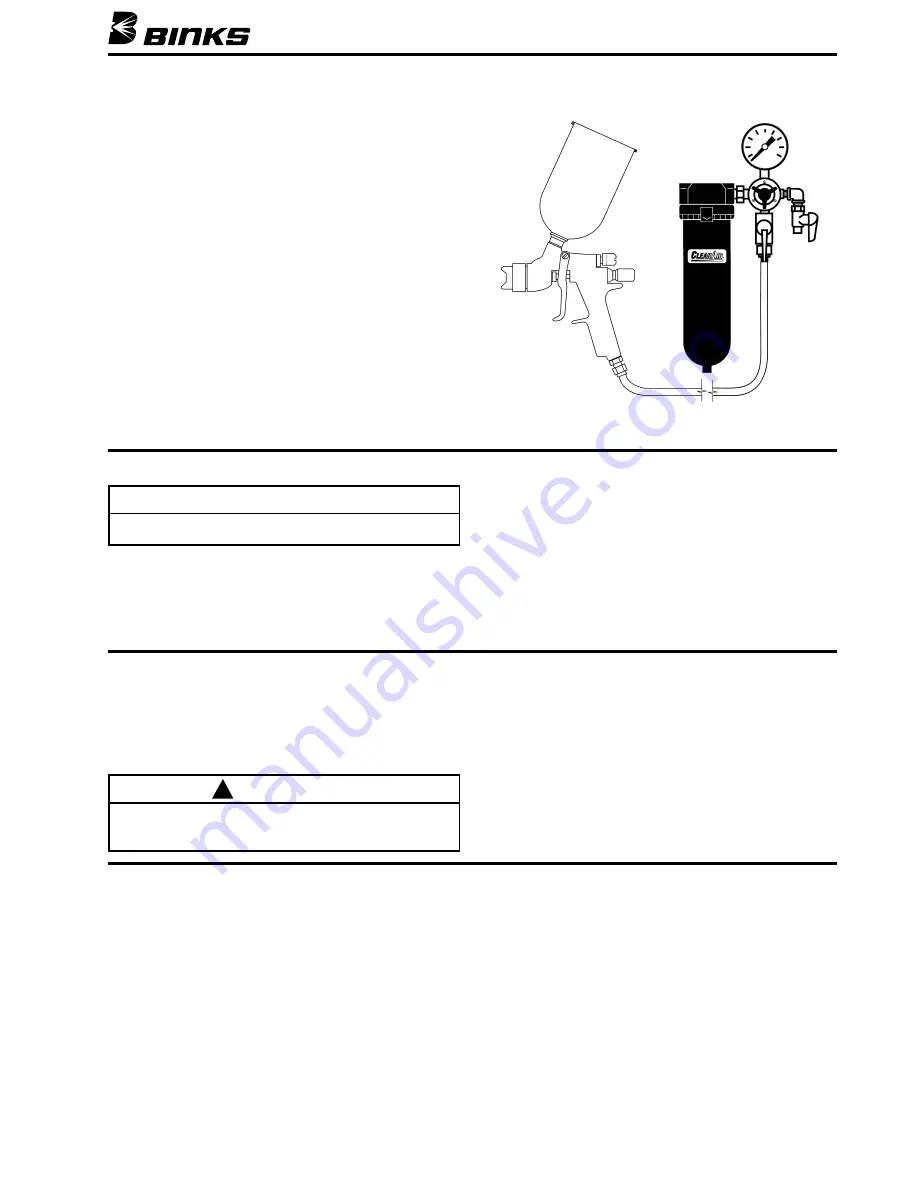

CONNECTING GRAVITY FEED CUP TO GUN

(Figure 1)

Screw the cup into the spray gun fluid inlet.

Fig. 1

OPERATING THE M1-G HVLP SPRAY GUN

CONTROLLING THE MATERIAL FLOW

Correct fluid nozzle size should be selected for proper

material flow rate. The material valve control knob (19)

may be used to restrict the material needle valve opening

and reduce the material flow as necessary.

CONTROLLING THE FAN SPRAY

The fan spray is controlled by means of the side port

control assembly (9). Turning this control clockwise until

it is closed will give a round spray. Turning it counter-

clockwise will widen the spray into a fan shape. The fan

spray can be turned anywhere through 360° by position-

ing the air cap (2) relative to the gun. To affect this,

loosen retainer ring, position nozzle, then tighten retainer

ring.

TROUBLE SHOOTING

FAULTY SPRAY

A faulty spray is often caused by improper cleaning,

resulting is dried materials around the material nozzle tip

or in the air nozzle. Soak these parts in thinners to soften

the dried material and remove with brush or cloth.

If either the air cap (2) or fluid nozzle (3) are damaged,

these parts must be replaced before perfect spray can be

obtained.

INTERMITTENT SPRAY

Fluttering spray is caused by either insufficient material

in the gravity feed cup or a clogged fluid passage. If the

fluid passage is clogged, drain material from the paint

cup and remove the cup and fluid nozzle. Clean the fluid

passage with solvent and reassemble.

Gravity Feed Cup

Air

Extractor

NOTE

All numbers in parentheses ( ) refer to item numbers in

Assembly Drawing on Page 6.

CAUTION

Never use metal instruments to clean the air or material

nozzles. These parts are carefully machined and any damage

to them will cause faulty spray.

!

Summary of Contents for M1-G HVLP

Page 10: ...10 NOTES ...

Page 11: ...NOTES 11 ...