8

GENERAL SPRAY INSTRUCTIONS

To reduce overspray and obtain maximum efficiency,

always spray with the lowest possible fluid/air pressure

that produces an acceptable spray pattern.

Excessive atomizing air pressures can increase overspray,

reduce transfer efficiency, and with some materials, result

in poor finish quality from dry spray. Atomizing air pres-

sures should not exceed 10 psi. See table on page 5, dia-

gram on this page and Regulatory Note on page 9.

Generally use 30 - 35 psi at gun inlet (see below).

Unusually heavy, difficult to atomize materials may

require up to 50 psi air at gun head.

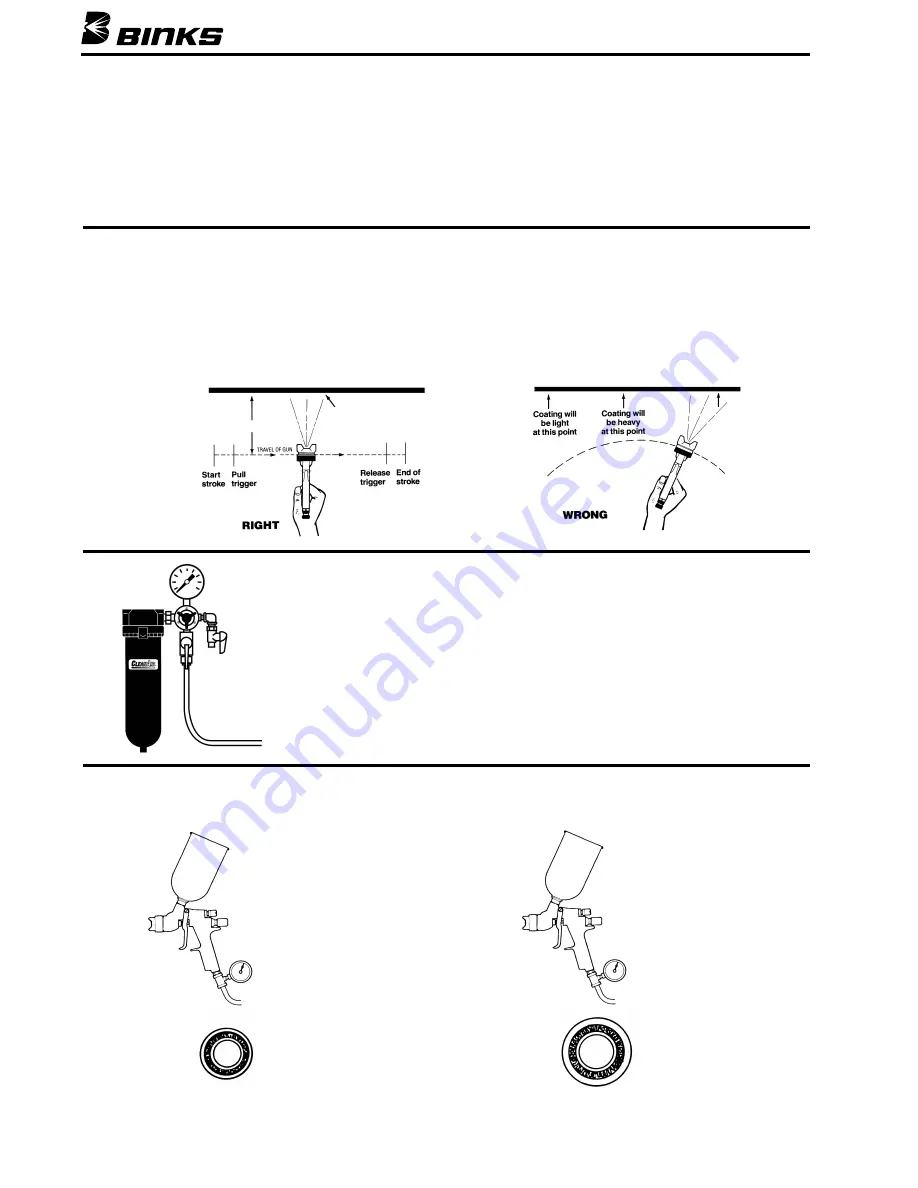

SPRAY TECHNIQUE

The first requirement for a good resultant finish is the

proper handling of the gun. The gun should be held per-

pendicular to the surface being covered and moved paral-

lel with it. The stroke should be started before the trigger

is pulled, and the trigger should be released before the

stroke is ended. This gives accurate control of the gun

and material.

The distance between gun and surface should be 6 to 10

inches depending on material and atomizing pressure.

The material deposited should always be even and wet.

Lap each stroke over the preceding stroke to obtain a uni-

form finish.

Oil and Water Extractor is important

Achieving a fine spray finish without the use of a good oil and water extractor is

virtually impossible.

A Regulator/Extractor serves a double purpose. It eliminates blistering and spotting

by keeping air free of oil and water and it gives precise air pressure control at the

gun. See page 3 regarding installation of extractors.

Atomizing pressure must be set to allow for the drop in air pressure between the

regulator and the spray gun.

Approx.

5 1/2 psi

at Nozzle

Approx.

9 psi

at Nozzle

Only 34 psi

at Gun Inlet

25 feet of

1/4" I.D. hose

causes a drop

of 26 psi

between the

air supply

and the gun.

48 psi

at Gun Inlet

25 feet of 5/16" I.D.

hose causes a drop

of 12 psi between

the air supply and

the gun. For this

reason we recommend

the use of 5/16" hose.

1/4"

5/16"

Cross section view showing comparison of

inside hose diameters (actual size). 60 lbs

regulated pressure.

HOSE RECOMMENDATION

With 60 psi applied at air supply:

RECOMMENDED

NOT RECOMMENDED

6 to 12 inches

Coating should be even

and wet when spraying

Summary of Contents for M1-G HVLP

Page 10: ...10 NOTES ...

Page 11: ...NOTES 11 ...