Page 7

© ITW Inc 2007

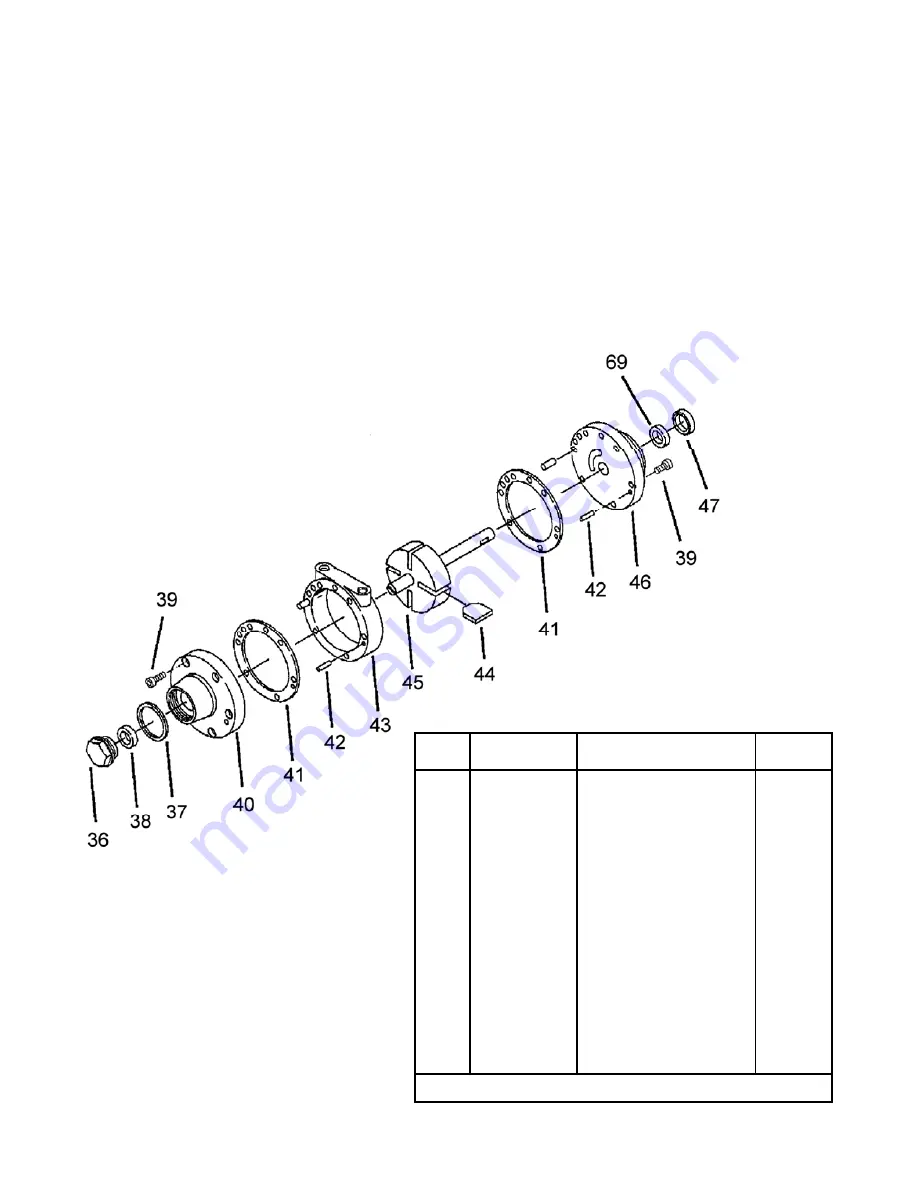

Fig 4

Ref.

No.

Replacement

Part No.

Description

Individual

Parts Req.

36 QS-190

End Cap

1

•

37

-

End Cap Gasket

1

38 PT-58

Bearing

1

39 Purchase Locally Machine Screw 1/4”-28 x 1/2”

1

40 QS-333

Front plate

1

•

41 PT-59-1-K10

End Plate Gasket Kit (kit of 10)

2

42 QS-189-1-K10

Dowel Pin (kit of 10)

4

43 QS-335

Body

1

•

44

-

Vane

4

45 QS-442

Rotor and Shaft Assy

1

46 QS-334

End Plate

1

47 QS-197

Bearing

1

68 QS-336

Oil Seal

1

•

Included in KK-5001-1 Air Motor Repair Kit.

end plates and rotor assembly. If scoring

exists, send unit to a Gast Authorized

Service Facility.

8. Check the bearings for signs of wear.

Replace the bearings at least every 2

years.

9. Place the drive shaft of the rotor

assembly (45) through the drive end

plate (46). Press the drive bearing (69)

onto the drive shaft using a bearing

pusher.

10. Using a suitable tool, lightly tap on inner

race of the drive end bearing (69) to

snug up rotor (45) to drive end plate

(46).

11. Check the vanes (44) for wear. If the

height of the vanes are less than

17.5mm (11/16”) then re-new the vanes.

Install new vanes (44), the angle cuts on

the vane face to the center of the rotor.

12. Place the end plate gasket (41) on the

body of dead end (40). If the original is

damaged, replace with a new one

supplied in the service kit.

13. Place the dead end plate (40) on the

body.

14. Install the dead end bearing (38) and

press into place with bearing pusher tool.

15. Install the dowel pins (42).

16. Fully tighten the remaining bolts to 8.5 -

11.3 Nm (75-100 in-lbs).

17. Set end clearance to the values at the

end of this section. lightly tap on the

inner race of the dead end bearing to

free up and center the rotor in the body.

18. Apply a small amount of grease to

bearing seal (47) and install the drive

end bearing seal by pressing flush with

bearing pushing tool from Tool Kit.

19. Reattach end cap (36) or (64) with new

gasket ((37).

20. Apply a few drops of 10w oil lubricant

into ports and rotate shaft by hand for a

few rotations.

End Clearances

Total clearance

.063mm (0.0025”)

Top end clearance

.038mm (0.0015”)