1

GENERAL INFORMATION

Thank you for purchasing a BioMicrobics FAST® system. One or more of the following patents protects this

process: 3,966,599; 3,966,608; 3,972,965; 5,156,742. If you have questions regarding any BioMicrobics

products, please contact us:

1-800-753-FAST (3278)

or

+1-913-422-0707

e

‐

ABOUT FAST

The FAST® (Fixed Activated Sludge Treatment) system uses naturally occurring bacteria (biomass) to treat

sewage for dispersal into the environment. This continuous process provides the biomass with food (waste)

and air in a suitable environment. Dead bacteria and non-biodegradable waste settle and accumulate in the

bottom of the tank for periodic removal.

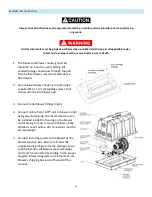

The FAST assembly consists of two components: the treatment module and blower. The blower provides air to

the system via the air supply pipe. The air supply pipe and draft tube create an airlift, which mixes oxygen and

waste throughout the media inside the tank. Bacteria, supported by air from the airlift, grows on the media

and digests the waste. Finally, a vent pipe expels vapors created by the process.

Always secure all access covers to prevent unauthorized people from entering the tank. Only

qualified service personnel should open access ports and/or covers.

Infectious organisms also exist in a septic tank. So if any contact with wastewater occurs,

immediately wash and disinfect all exposed areas and contact personal physician. Failure to

do so could result in severe sickness or death.

DO NOT use an open flame or cause a spark near a septic tank’s access points. Gases

emanating from septic tanks can explode if ignited or deadly if inhaled.

Summary of Contents for HighStrengthFAST 4.5

Page 2: ...1...

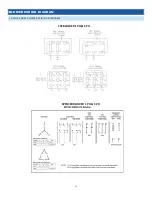

Page 15: ...12 FUJI BLOWER 1 PH FUJI BLOWER 3 PH...

Page 16: ...13 GAST BLOWER 1 PH...

Page 19: ...16 3PH 208V 240V 1PH 208V 240V 3PH 460V...

Page 20: ...17 CONTROL PANEL SCHEMATICS...

Page 21: ...18...

Page 22: ...19...

Page 23: ...20...