10

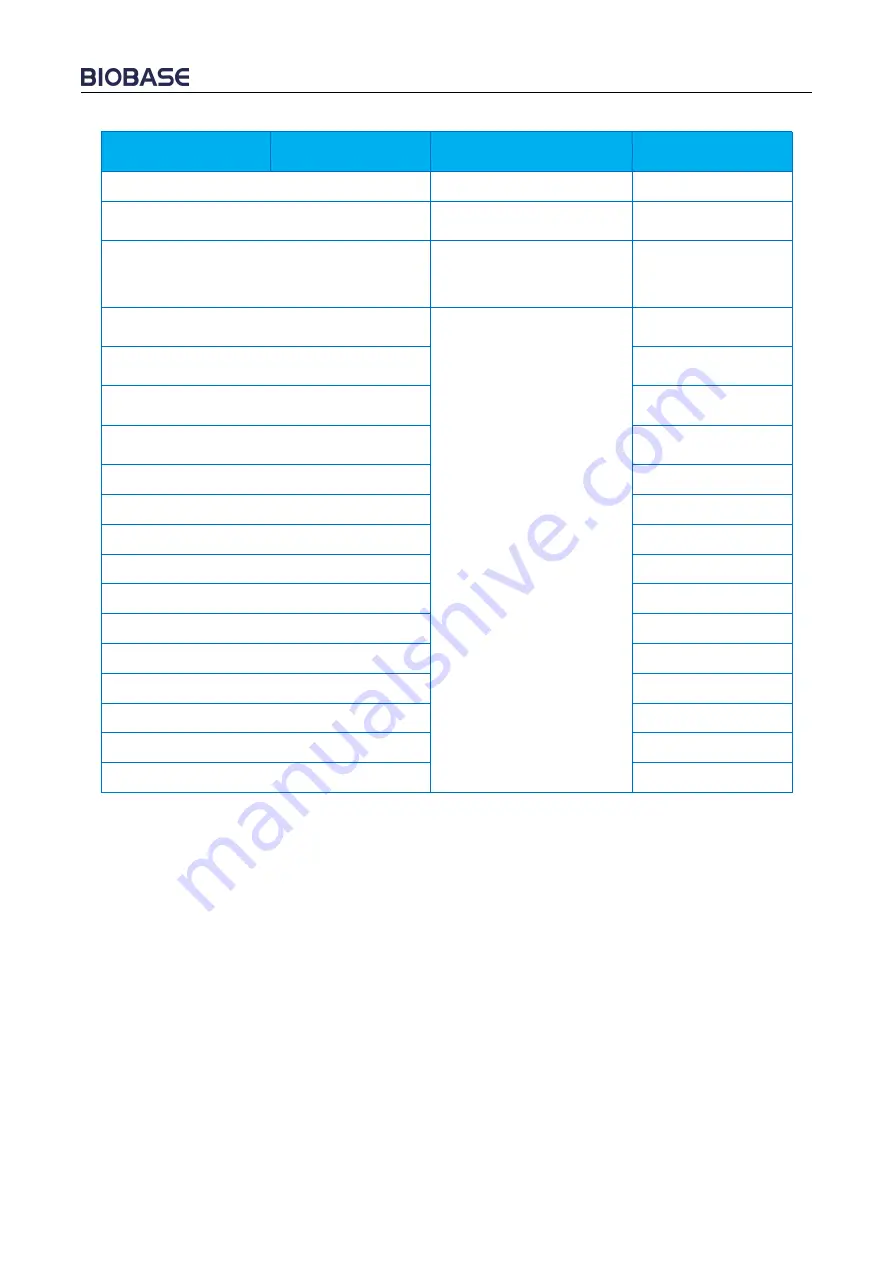

BSC-2FA2-HA Packing List

Items

Model

Position

Quantity

Main Body

Wooden box

1 set

Base Stand

Back of main body

1 set

UV Lamp (T6 15W)

Top or back of main

body

1 pc

Protective fuse(12.5A, 250V)

Placed in a transparent

plastic bag

2 pcs

Protective fuse(6.3A, 250V)

1 pc

Protective fuse(2.5A, 250V)

2 pcs

Protective tube(63mA, 250V)

1 pc

Power Cord

1 pc

User manual

1 copy

Test report

1 sheet

Quality certification card

1 sheet

Drain Valve

1 set

Stainless steel hex cylinder head bolt

M10×20

5 pcs

Stainless steel flat washer10

5 pcs

Stainless steel spring washer 10

5 pcs

Inner hexagon wrench

1 pc

Big rubber gasket

1 pc

Small rubber gasket

1 pc

3.3 Installation conditions and using environment

To avoid disturbances to the safety cabinet and its operator, follow the following guidelines, while

determining a suitable location for the cabinet:

Microbiological Safety Cabinet should be placed in airflow protected area. Front window operation

door shouldn’t be against over door or window, but far away from Ventilation and air conditioning

vents. In order to against outside various high-speed current of air to interference of operation area,

such

as

door,

window,

fan,

draught

of

sending

air,

compressed

air

etc.

Test shows that if other interference airflow exceeds the intake airflow rate of the safety ca

binet, the indoor air will enter the working area of the cabinet.So it is very necessary to place the cabi

net in the correct position.It should also pay attention to the relationship between the safety cabinet e

xhaust air and indoor ventilation airflow or exhaust duct.Exhaust air discharged from the top , When

placing the cabinet, it should avoid restricting its exhaust.Biological safety cabinets should be in the

direction of the air flow downstream and the side of the security cabinet at least 300mm space to help

check.