TG

RADIENT

Manual ___________________________________________________________ 7

3.4

Initial self test

After switching on the TG

RADIENT

the serial number of the instrument and the software version

is displayed.

TGradient

Serial No 1234567

Vers. 4.00 op

The TG

RADIENT

checks all programs in all directories (so called RAM check).

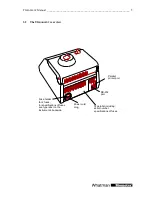

3.5

The TGradient display

The TG

RADIENT

display provides information about the instrument and about the status of the

active program.

prog

step

temp[°C]

25.2°C

time

lid

25.4°C

A ?

B start/stop

C programs

D +

The individual function of the special keys A , B , C and D are specified in the display and

depend on the context.

3.6

Handling of the adjustable heated Lid

To achieve optimum pressure on the tubes the TG

RADIENT

is equipped with an height adjustable

heated lid.

Close the lid:

After the samples have been placed in the block close the lid. Turn the wheel clockwise until you

hear a clicking noise. In this mode the pressure will not increase further, even when you keep on

turning the wheel.

Note:

The pressure of the lid has been optimize for a fully loaded block. If only very few tubes

are loaded to the block you should place dummy tubes in the four corner positions to avoid

damage of tubes by excessive pressure.

Open the heated lid:

First:

Release pressure by turning the wheel counter clockwise. As soon as there is no more

resistance the pressure has been released.

Then:

now you can open the lid with the knob.

Important:

The lid should not be opened under pressure because this leads to damage of the

locking mechanism.