P

AGE

10

OF

25

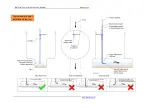

7.

Fill Timer Blocks in the Venturi Sampler PLC.

Block No. Block Description

Default Value

Unit

B106

Timers used to control the purge sequence for up to 4 or 6

optional stream valves, for 4 and 6 stream venturi sampler

option.

ON: 40

OFF: 1

ms

B126

161 / 241

ms

B147

16 / 24

s

B148

Purge chamber and line prior to filling timer.

20

s

Note: Some applications may have a certain size particulate separation chamber

“External Chamber”

option which gathers and settles the sample at the sampling point prior to the Venturi Sampler is filled

with the sample. In applications where this chamber is present, B170 & B172 are changed from the

default zero second value to the site specific values.

B170

External chamber fill time.

0

s

B172

External chamber settling time.

0

s

B155

This block serves two purposes:

1. There are liquid sensors to stop the Venturi fill sequence

once sample is detected. If no sample is detected within

the duration of this block the fill sequence is automatically

stopped and a fill error activated, this could be due to dry

stream etc. The BioTector Sample valve opens once this

timer elapses also.

To account for variations in the stream the duration of this

block should be longer (~40%) than the typical time taken

for the sensors to detect sample once the ‘Filling Sampler’

message appears on the PLC Display.

2. If the sample is successfully detected during this timer the

sample is allowed to settle while the timer elapses. If the

site conditions require some settling of the sample prior to

sampling by the BioTector then this timer can be extended

to accommodate this need.

100

s

Default FILL SEQUENCE TIME 4 Stream

136

s

Default FILL SEQUENCE TIME 6 Stream

144

s

Note: B126 not included in calculation of FILL SEQUENCE TIME

The SAMPLER time in the BioTectors SAMPLE PUMP menu must be greater than FILL SEQUENCE

TIME of the Venturi Sampler. The FILL SEQUENCE TIME in seconds can be found by pressing the [+]

key on the PLC while in Standby Mode. This will automatically adjust if times are changed from default

settings to show the new FILL SEQUENCE TIME.

In the default configuration the fill sequence of the Venturi sampler takes 136 seconds, this allows 100s

for the Venturi sampler to fill its tubes and chamber, (the other ~40 seconds being used for the initial

purge of the Venturi sampler). This configuration is suitable for sites with a 40m sample line and a lift up

to approximately 5 to 6 meters. Longer sample lines will require the default time in both the Venturi

samplers PLC and BioTector Sampler setting to be changed.