P

AGE

5

OF

25

2.

Venturi Sampler

The Venturi Sampler has 2 possible build options, depending on its construction.

Build Option 1:

The Venturi Sampler can be designed to collect a pressurized sample liquid, reduce the pressure of this

liquid sample to ambient pressure, and supply this sample to the BioTector.

The Venturi Sampler also returns the spent sample back to the pressurised sample point.

Build Option 2:

The Venturi Sampler can be designed to collect a sample of liquid at ambient pressure, from a depth of

up to 7 meters (measured from the bottom of the sampler to the lowest liquid level in the sump, at sea

level), and supply this sample to the BioTector at ambient pressure. The vacuum used in the sampler is

generated with a Venturi pump.

The sampler also returns the spent sample back to the sample point.

Sensor Options:

The Venturi Sampler will have been supplied with one of the sensor options below:

1. Two capacitive level / liquid sensors supplied to detect the sample.

2. One ultrasonic level / liquid sensors supplied to detect the sample.

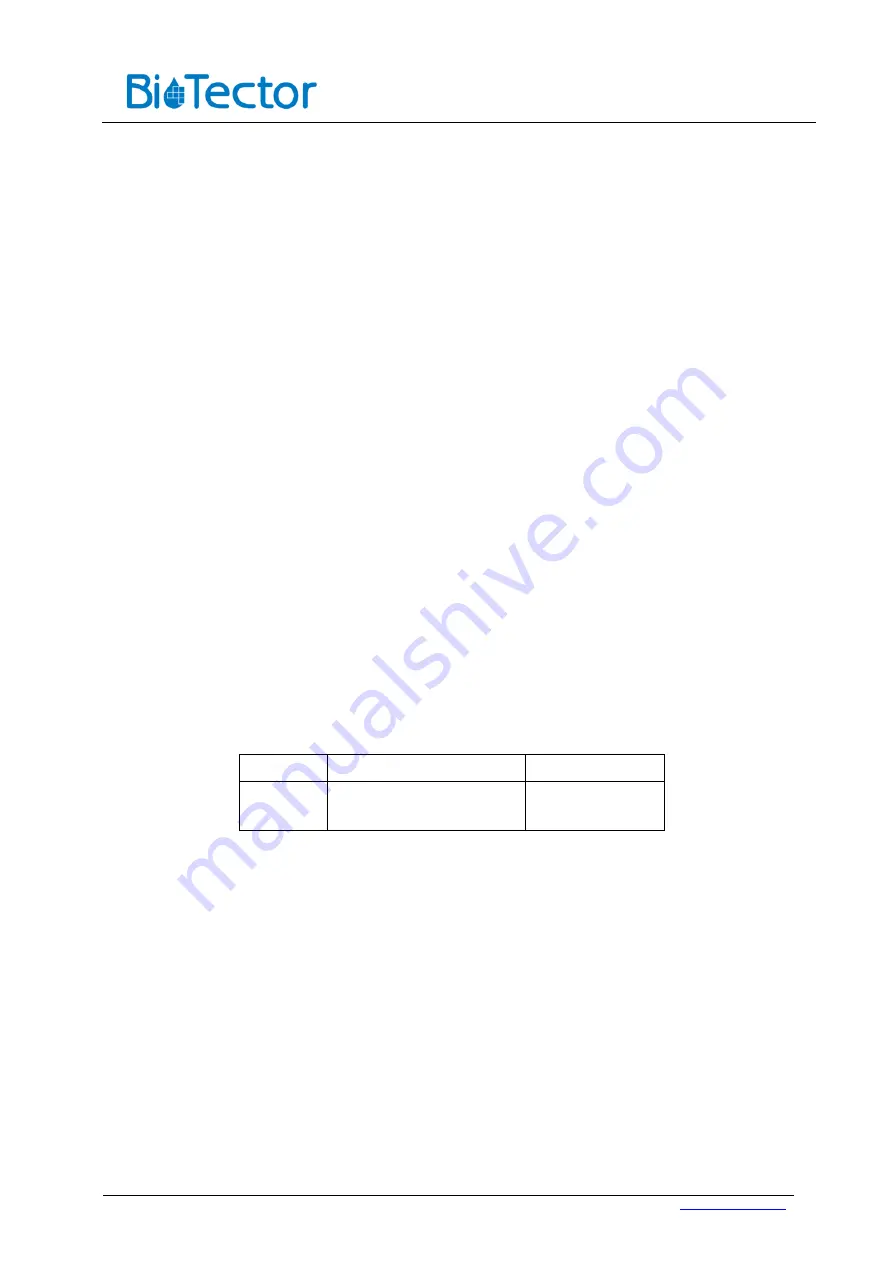

Systems built with an Ultrasonic sensor, the sensor is enabled on the PLC. Below table shows the

example block settings of a Venturi Sampler with enabled and disabled Ultrasonic Sensor.

Block No.

Block Description

Value

B231

Ultrasonic Sensor Enable

0 = Disabled

1 = Enabled

Utilities

Feed Air requirement: typically 6 bars, 50 LPM when venturi is running.

Purge air requirement, typically 100 LPM at 3.5 bars.

Air must be water, oil and dust free (-20°C dew point).

Wash water requirement: 3 bar with customer supplied regulator fitted.

Usage typical 10 liters per hour.

Water can be heated up to 90C if required for hot water backwash.

Note, blowback pressure for water and air must be 1.5 times the sample pressure.

For additional details, please see BioTector Venturi Sampler Technical Specifications.