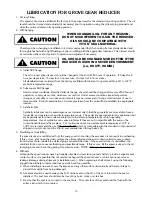

LUBRICATION FOR GROVE GEAR REDUCER

1. Factory Filling

The speed reducers are oil filled at the factory to the proper level for the standard mounting position. The oil

level should be checked and adjusted (if necessary) prior to operation, using the oil level plug provided and

while the unit is oriented in its operating position.

2. Oil Changing

WHEN CHANGING OIL FOR ANY REASON,

DO NOT MIX DIFFERENT OILS IN THE REDUCER.

OILS SHOULD BE COMPATIBLE WITH

VITON

®

SEAL MATERIAL.

Therefore, when changing to a different oil, it is recommended that the housing be completely drained and

thoroughly flushed with a light flushing oil prior to refilling with the appropriate lubricant. The oil level should

be rechecked after a short period of operation and adjusted, if necessary.

OIL SHOULD BE CHANGED MORE OFTEN IF THE

REDUCER IS USED IN A SEVERE ENVIRONMENT

(i.e., DUSTY, HUMID)

A. Initial Oil Change

The oil in a new speed reducer should be changed at the end of 250 hours of operation. (30 days for 8

hour per day service, 15 days for 16 hour service, 10 days for 24 hour service.)

All standard reducers ordered from the factory are filled with lubricant to operate within a 30° to 100°F

ambient temperature range.

B. Subsequent Oil Changes

Under normal conditions, after the initial oil change, the oil should be changed after every 2500 hours of

operation, or every six months, whichever occurs first. Under severe conditions (rapid temperature

changes, moist, dirty or corrosive environment) it may be necessary to change oil at intervals of one to

three months. Periodic examination of oil samples taken from the unit will help establish the appropriate

interval.

C. Synthetic Oils

Synthetic lubricants can be advantageous over mineral oils in that they generally are more stable, have a

longer life, and operate over a wider temperature range. These oils are appropriate for any application but

are especially useful when units are subjected to low start-up temperatures or high operating

temperatures. Use of synthetics can cause problems if they are not compatible with the seals or the

conventional lubricants they replace. For continuous duty at normal ambient temperatures (-10°F to

105°F) we recommend the use of Mobile SHC 634 which is compatible with the standard compounded oil

shipped in our product and the Viton® seal material used through size 252.

3. Overfilling or Underfilling

If a speed reducer is overfilled with oil, the energy used in churning the excessive oil can result in overheating.

If this occurs, shut down the drive, remove the oil level plug and allow oil to drain until oil ceases to drain

from the level hole, reinstall the oil level plug and restart the drive. if the speed reducer is underfilled, the

resultant friction can cause overheating and possible damage. If this occurs, fill the speed reducer to the oil

level plug hole and check the gearing for excessive wear. NOTE: Oil capacity is 1¾ pints.

4. Oil Seals

Although the speed reducer uses high quality oil seals and precision ground shafts to provide a superior seal

contact surface, it is possible that circumstances beyond the speed reducer's control can cause oil seal

leakage (damage during shipment or installation, etc.). When replacing a shaft oil seal, using the following

suggestions will help to insure leak-free operation and long seal life.

A. When installing a new seal, cover the keyway and any other surface discontinuity with smooth tape to

protect the seal lip from being damaged.

B. A sealant should be used between the O.D. of the seal and the I.D. of the bore into which the seal is

installed. The seal bore should also be free of any burrs, nicks, or scratches.

C. Be sure that the seal is not cocked in the seal bore. The outer face of the seal should be flush with the

surface into which it is mounted.

10

Summary of Contents for VTS-100

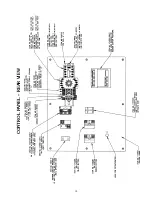

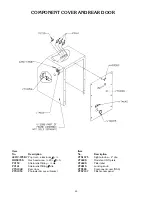

Page 17: ...15 CONTROL PANEL REAR VIEW ...

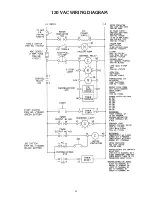

Page 23: ...120 VAC WIRING DIAGRAM 21 ...

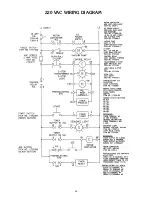

Page 24: ...220 VAC WIRING DIAGRAM 22 ...

Page 26: ... NOTES 24 ...