VTS1053

PHOTOELECTRIC EYE

OPERATING INSTRUCTIONS

Starting Operation

1. Open the cover and guard of the sensor; make sure that no dirt enters the device.

2. Select switching function:

L.ON: Light-switching if light received, output (Q) switches.

D.ON; Dark-switching if light interrupted, output (Q) switches.

WT 260-R and -S only: Light-switching: Relay 1x u, separated galvanically.

3. With following connectors only:

Connect and secure cable receptacle tension-free

Only in versions with terminal clamp area:

Loosen ½" PF screwed connection, remove sealing plugs.

Cable outlets downward or to the back. Pass the dead power supply line through and connect the sensor

according to connection diagram.

4. Close the protective cap.

Mount the sensor using the mounting holes and align it roughly.

Connect the operating voltage to the sensor (see Type imprint).

Check scanning distance, and compare with characteristic in diagram (x = scanning distance, y = operating

reserve).

Reflectance: 6% = black, 18% = gray, 90% = white (based on standard white to DIN 5033).

Aligning light reception:

Position the object. Align the WT 260 with the object. Turn the knob >SENS, <to max. When the light

reception is optimal, the switching output switches into the state set in.

If no or too little light is received, realign the photoelectric proximity switch with the object and check the

application conditions.

5. Setting the sensitivity (SENS):

Remove the object. The switching output switches (Pos. A = Max).

When there is interference from the background:

Turn the knob (turning range 270º) in the direction of min. (e.g. position A). Set the rotary knob to min.

Position the object. Turn the knob in the direction of max. until the switching output switches (e.g.

position B).

If position B < position A:

Select the middle setting (e.g. position C). Check overall operation. If operation is OK, setting is

completed. IF operation is not OK, check the application conditions and realign.

If position A < position B:

Background influence is excessive. Check the application conditions and realign. Check sealing faces,

seals, and screwed joints, then replace and screw down cover.

Maintenance

SICK photoelectric switches do not require any maintenance.

We recommend that you clean the optical interfaces and check the screw connections and plug-in

connections at regular intervals.

12

Summary of Contents for VTS-100

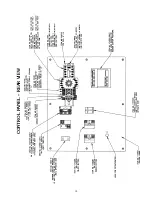

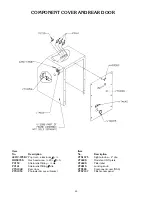

Page 17: ...15 CONTROL PANEL REAR VIEW ...

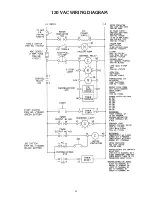

Page 23: ...120 VAC WIRING DIAGRAM 21 ...

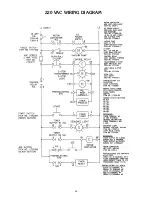

Page 24: ...220 VAC WIRING DIAGRAM 22 ...

Page 26: ... NOTES 24 ...