10

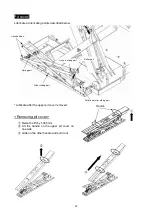

This is switch for raising and lowering the lift and arms.

●

Switch for raising and lowering lift

Press Up button to raise the lift and release it to stop the lift at that

position.

Press Down button to lower the lift and release it to stop the lift at

that position.

The Up and Down buttons cannot be operated at the same time.

●

Switch for raising and lowering arms

Use these switch when the lift is at the lowest lowered position.

Press Up button to lift the arms to the swinging height.

Press Down button to lower the arms to be stored.

Down button can only be used when the lift at the lowest lowered

position.

The Up and Down buttons cannot be operated at the same time.

The lengths of sliding supporters can be adjusted in variable range of 1,320 to 2,200 mm, depending

on jack points of the vehicle being lifted. There is a knotch for pulling on the upper surface of the

sliding part. Slide the sliding supporter using the knotch for pulling.

Push button control switch

Sliding Supporter

Make sure that the sliding supporter is completely stored when storing the sliding supporter.

For raising and

lowering the lift

For raising and

lowering arms

When stored

When sliding

Sliding supporter

Knotch for pulling

Caution

Up

Up

Down

Down

Lift

Arm