4

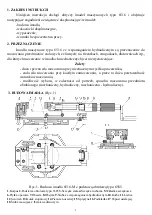

Final clamping of the workpiece is realised with hydraulic system. Maximum clamping force is

achieved when the housing of the lead screw is tightened with the crank as far as it goes

(see p. 6).

Application of crank extenders, hammering of the crank for „firmer” clamping of the workpiece

or further turning the crank despite of reaching by the housing the left extreme position is

inadmissible and can lead to damage to hydraulic screw.

CAUTION

!

In vices of this type during clamping with hydraulic servo the clamping force

can reach high values within short time. In view to this fact, clamping with hydraulic

servo is recommended only for clamping of steel or cast iron workpieces or elements made

of materials of similar resistance, which are not liable to deformation.

Workpieces made of soft, easy deformable materials as: aluminium, plastic, etc. as well as

wire, thin-walled details can be clamped only with mechanical method and with

disconnected hydraulic servo

(see p. 6.2).

In case of non-observance of above-mentioned recommendation,

the internal clutch can be

locked, what results in lack of sufficient clamping force during further operation.

The symptom of such situation is lack of perceptible resistance on the crank when the moveable

jaw comes into contact with the workpiece.

In such case to

unlock the clutch

: hold down the housing of lead screw with left hand and turn

the crank anticlockwise with right hand until we feel slight „click” of clutch mechanism.

This should restore proper operation of screw mechanism.

If this method gives no result, the hydraulic mechanism is probably internally damaged. In such

case authorised personnel should repair the screw (see p. 7 Maintenance of the screw).

It is also possible to send inoperable hydraulic screw to the manufacturer for repair (payable).