(12) BISSELL BigGreen Commercial FMT Dual-Speed Floor Machine

BISSELL BigGreen Commercial FMT Dual-Speed Floor Machine (9)

4.0 Operating Tips

• For indoor use only. Sweep abrasive soils before

scrubbing.

• While the brush or pad driver is spinning, keep the floor

machine moving to avoid “donut” burns on the floor.

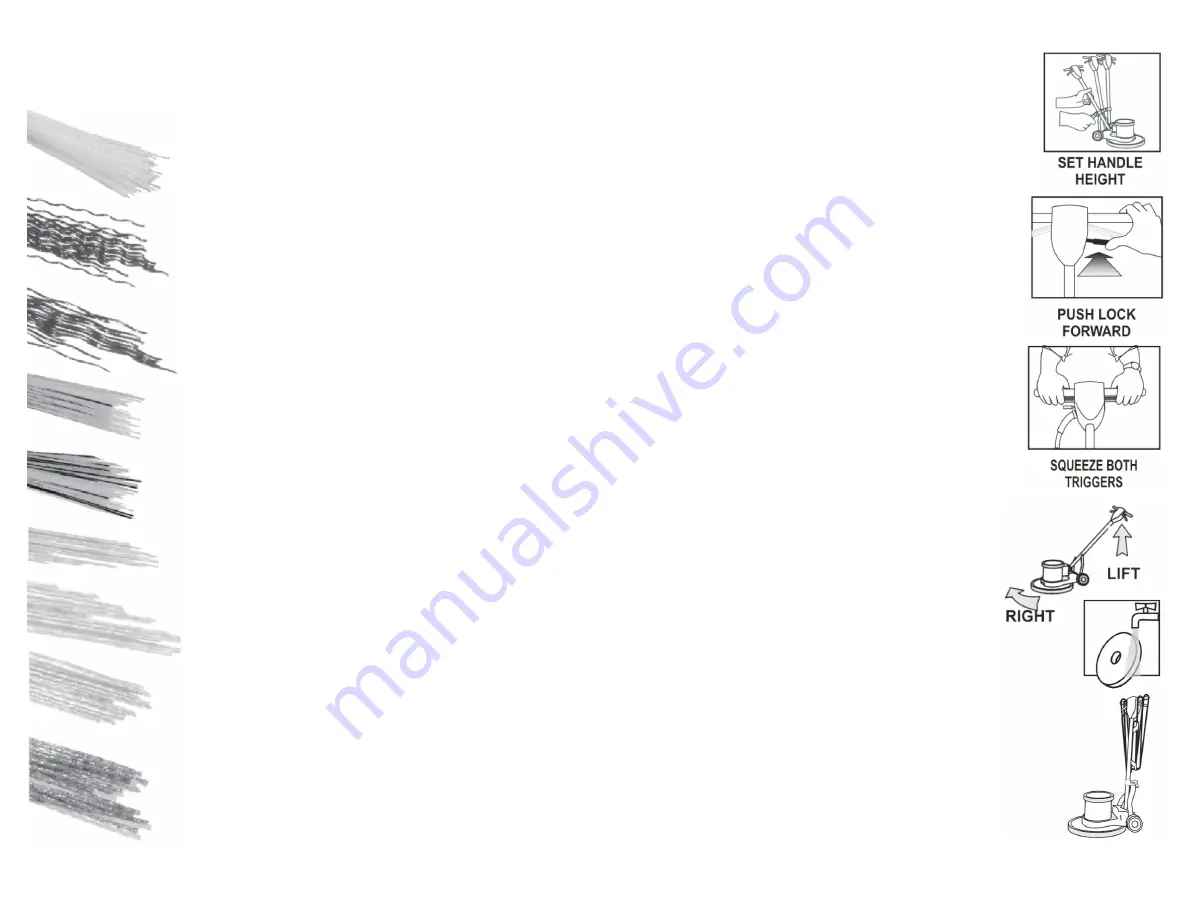

To Start Operation:

• Unlock the handle by raising the locking lever.

• Lower the handle to a comfortable position, typically

waist height.

• Relock the handle by pushing the lever down. NEVER

OPERATE THE MACHINE WITH THE HANDLE

UNLOCKED.

• This floor machine is a high torque motor. Hold the

machine firmly with both hands when starting up.

• Push the red safety interlock switch forward to unlock the

dual triggers.

• Squeeze the dual triggers to release power to the motor.

Once power is on, either trigger will keep power to the

motor.

• To stop the floor machine release both triggers.

• The spinning brush helps move the floor machine. (Lift the

handle slightly to work to the right. Push the handle down

slightly to work to the left.)

4.1 To Store your Machine

• Lock the handle in the “up” position. Tilt the machine

back and remove the pad driver or brush.

• Wind the cord around the handles and the bottom cord

hook.

• Wash brushes or pads and hang to dry. Never store

machine standing on the brush.

• Inspect and maintain equipment on a regular schedule for

best results.

• Check and clean pads after each operation. Remove soil

and chemical buildup. Replace worn or damaged pads.

• Check the triggers and switches for proper operation.

• Repair or replace damaged skirts and dumpers.

• Use air pressure or vacuum to remove dust and debris

from the motor vents.

• Report problems and repair promptly.

6.2 Scrubbing Brush Filaments

Scrubbing brushes are available with a range of bristle types - from the softest for

high-gloss floors, to the most aggressive for heavy soils. Match your brush to the

floor as you match a detergent with the soils.

Nylon is used for general scrubbing. Because nylon softens when

wet, it is great for gentle scrubbing, mopping and polishing of

decorative floors. Nylon will not scratch tile, terrazzo or coated

surfaces. Nylon brushes are durable and long lasting.

Polypropylene is a common choice for general purpose

scrubbing and works well on both concrete and on coated floors.

Polypropylene brushes typically cost less than nylon, but do not

last as long.

Non-scuff poly is a finer diameter (0.015-0.018”) filament used

for lighter duty scrubbing conditions and on waxed or finished

floors.

Bassine is a soft, natural fiber. The end of the bristle splits or

“flags” to build a polishing surface.

Union mix is a mixture of bassine and tampico (another natural

fiber). The mixture is stiffer than bassine alone and is used by

more traditional cleaners for scrubbing. It is often replaced by

poly.

Soft abrasive bristle is a 0.018” nylon filament extruded with a

500 grade grit. It is used for gentle scrubbing and is as aggressive

as a white scrub pad.

Daily abrasive bristle is a 0.035” nylon filament with 180 grade

grit. It is used for daily scrubbing of resilient tile and finished

floors and is as aggressive as a red scrub pad.

Stripper abrasive bristle is a 0.022” nylon filament with 120

grade grit. It is used for aggressive scrubbing and light stripping

of resilient floors, terrazzo and concrete. It is as aggressive as a

blue scrub pad.

Heavy-duty stripper abrasive bristle is a 0.050” nylon filament

with 80 grade grit. It is used for very aggressive scrubbing and

stripping of concrete, brick and quarry file. It is as aggressive as a

black scrub / strip pad.