KB-120-8

21

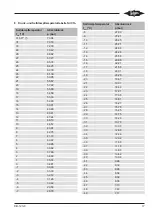

2.3.1

General safety references

DANGER

Observe the high pressure levels of the refriger-

ant CO

2

(critical temperature 31.06°C corres-

ponds to 73.6 bar, see chapter Pressure and

saturated vapour temperature table for CO₂,

page 34)!

At standstill the pressure in the system will rise

and there is a risk of bursting!

Install pressure relief valves on the compressor

and on the suction and high-pressure sides in

system sections that are lockable from both

sides.

Requirements and design according to

EN 378-2 and EN 13136.

DANGER

Dry ice may block the pressure relief valves!

Risk of bursting!

Do not mount any pipes near the outlet of the

pressure relief valve.

DANGER

Liquid CO

2

evaporates quickly, cools down at

the same time and forms dry ice!

Danger of cold burns and frost bites!

Avoid uncontrolled deflating of CO

2

!

When filling the system with CO

2

, wear gloves

and goggles!

CO

2

systems typically show low fluid temperatures. De-

pending on the system type and design, the following

measures are required:

• Condensers and liquid receivers or only the liquid re-

ceivers and possibly the heat exchanger must be in-

sulated to prevent the temperature from falling below

the dew point.

• If necessary, take other measures to limit the pres-

sure, such as:

– Use of a pressure equalisation vessel.

– For larger systems: installation of an additional

cooling unit to limit the pressure by back condens-

ation.

Maximum allowable pressures (standstill):

2MME-07K .. 6PME-40K

• Low pressure side: 100 bar

• High pressure side: 100 bar

2NSL-05K .. 4NSL-30K

• Low pressure side: 30 bar

• High pressure side: 53 bar

Due to the lower max. permissible pressure levels at

the low pressure side types 2NSL-05K .. 4NSL-30K are

equipped with a pressure relief valve (low pressure

side) to the atmosphere. According to EN 12693-2008

this pressure relief valve is not designed for protecting

the system. It only protects the compressor against in-

admissibly high pressures as soon as it (the com-

pressor) is shut off at both sides. The pressure relief

valves are attached to the suction shutoff valve. When

operating the compressor, open suction shutoff valve

completely (the pressure relief valve then becomes in-

active).

For compressors with line start permanent magnet mo-

tors (LSPM):

WARNING

Strong magnetic field!

Keep magnetic and magnetizable objects away

from compressor!

Persons with cardiac pacemakers, implanted

heart defibrillators or metallic implants: maintain

a clearance of at least 30 cm!

!

!

NOTICE

The PTC temperature sensor integrated in the

stator as a standard protects the LSPM motor

from overload when the temperature rises (e. g.

in case of prolonged locked rotor conditions). It

is recommended installing an additional over-

load protective device that reacts more quickly,

since repeated locking conditions would dam-

age the magnets.