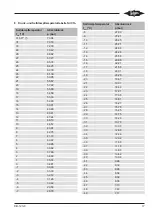

KB-120-8

22

3

Application ranges

2MME-07K .. 6PME-40K

• Low-temperature applications in cascade and

booster systems.

• Medium-temperature applications with higher con-

densing temperatures (only 2MME-1K .. 2DME-7K).

• Maximum allowable pressures on the low pressure/

high pressure side: 100 / 100 bar.

2NSL-05K .. 4NSL-30K

• Low-temperature applications in cascade and

booster systems.

• Maximum allowable pressures on the low pressure/

high pressure side: 30 / 53 bar.

Compressor types

2NSL-05K .. 4NSL-30K

2MME-07K .. 6PME-40K

Permitted refrigerant

CO

2

①

CO

2

of purity class N4.5 or comparable, or H

2

O < 5 ppm

Oil charge

BSE60K: standard oil charge

BSE85K, BSE68K: optional

Application limits

see brochure KP-120

see brochure KP-122

Tab. 1: Application ranges of subcritical CO

2

compressors

Information

BSE60K for cascade systems!

BSE85K for booster systems!

①: The CO

2

purity class can have a higher H

2

O level if

the system is filled through a generously dimensioned

filter drier. It is recommended changing the filter drier

several times after commissioning.

②: Standard speed range for capacity control with fre-

quency inverter:

• 2MME-07K .. 2DME-7K: authorised for 30 Hz to

75 Hz operation.

• 4FME-7K .. 4DME-10K: authorised for 25 Hz to

70 Hz operation.

• 4TME-20K .. 4PME-25K: authorised for 25 Hz to

70 Hz operation.

• 6TME-35K .. 6PME-40K: authorised for 25 Hz to

70 Hz operation.

• 2NSL-05K .. 2CSL-6K: authorised for 30 Hz to 75 Hz

operation.

• 4FSL-7K .. 4NSL-30K: authorised for 25 Hz to 70 Hz

operation.

In applications with high pressure ratios, the adjustable

speed range may be limited. Consultation with BITZER

is required.

Special applications

Flooded systems require special measures for oil re-

turn. Moreover, given the usually very low suction gas

superheat, a generously sized heat exchanger to in-

crease the suction gas temperature is required. This

also applies to medium-temperature applications in

cold water systems using the compressors 2MME-1K ..

2DME-7K.

When designing such systems, consultation with

BITZER is recommended. For applications in hot gas

defrosting systems, consultation with BITZER is also

recommended.

Filter drier

The solubility of water in gaseous CO

2

is much lower

than in other refrigerants. This means that, especially in

low temperature applications, even a relatively small

amount of moisture from the refrigerant can freeze out

and block or clog the control valves. Therefore a gener-

ously sized filter drier and a sight glass with moisture

indicator for CO

2

are necessary.