Rev. 1.00

- 76 -

SRP-275II

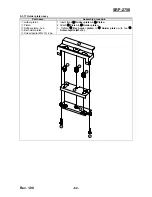

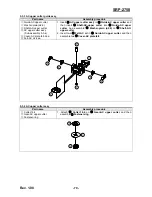

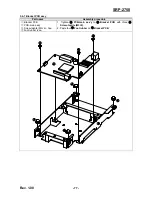

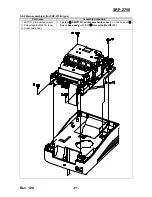

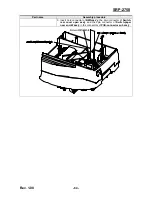

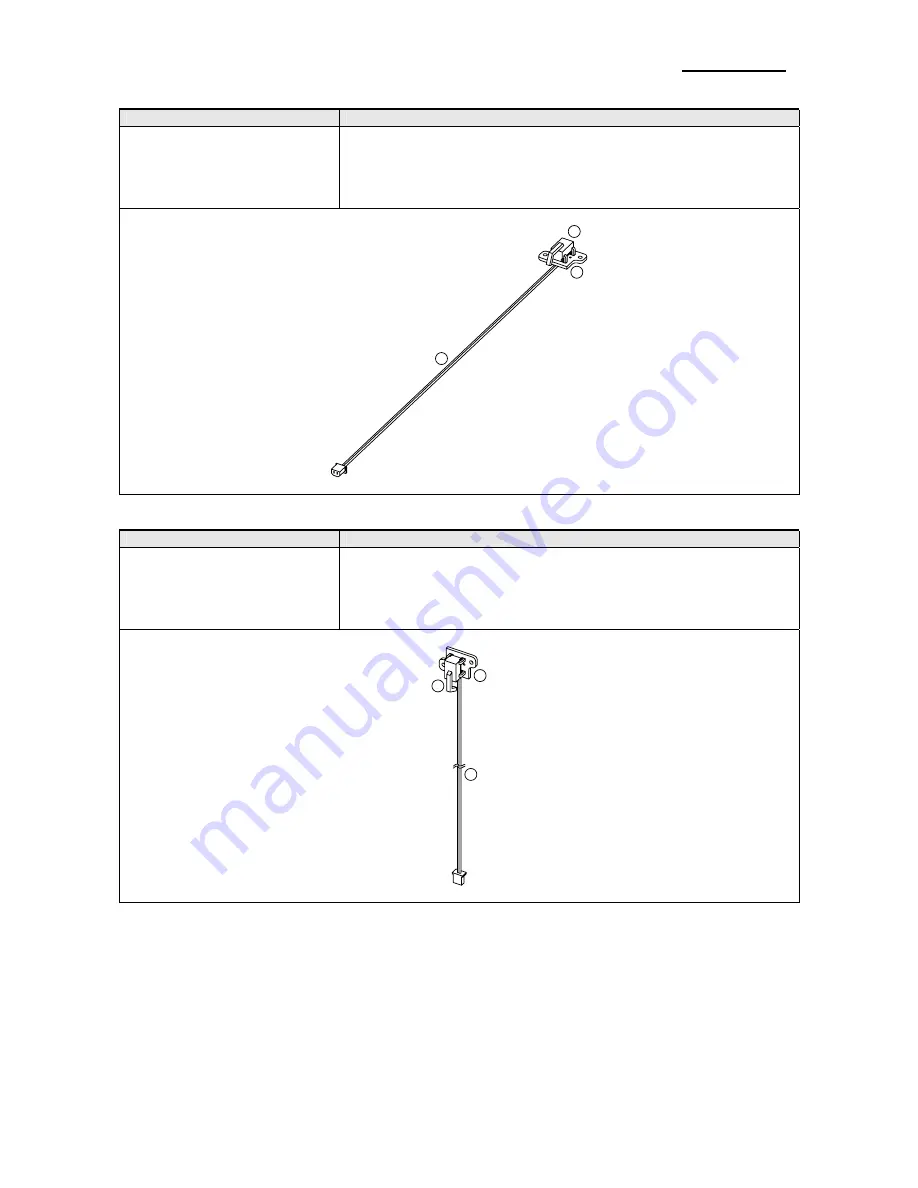

5-4-5 Switch-cover open assy

Part name

Assembly procedure

PCB

①

-switch-cover open

Switch

②

-micro (5.9gf)

Harness

③

-switch-cover open

1. Insert

Switch

②

-micro (5.9gf)

to

PCB

①

-Switch-cover open

.

2. Solder the land on

PCB

①

-Switch-cover open

bottom side and

attach

Harness

③

-Switch-cover open

on the land.

<Check point>

After soldering, check the frozen lead and short.

1

2

3

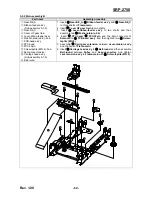

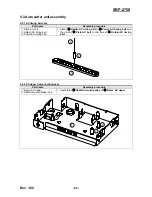

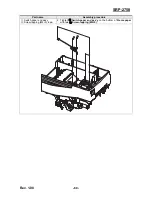

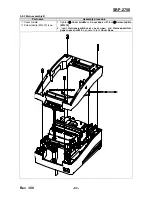

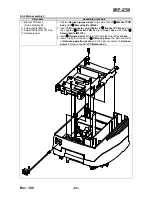

5-4-6 Switch-paper near end -W assy

Part name

Assembly procedure

①

PCB-switch-paper near end-W

Switch

②

-micro (5.9gf)

③

Harness-switch-paper near end

1. Insert

Switch

②

-micro (5.9gf)

to

PCB

①

-Switch-paper near end-W

.

2. Solder the land on

PCB

①

-Switch-paper near end-W

bottom side

and attach

Harness

③

-Switch-paper near end-W

on the land.

<Check point>

After soldering, check the frozen lead and short.

2

1

3