Operation

Instruction manual GSP

46 / 92

38107010002 en-US

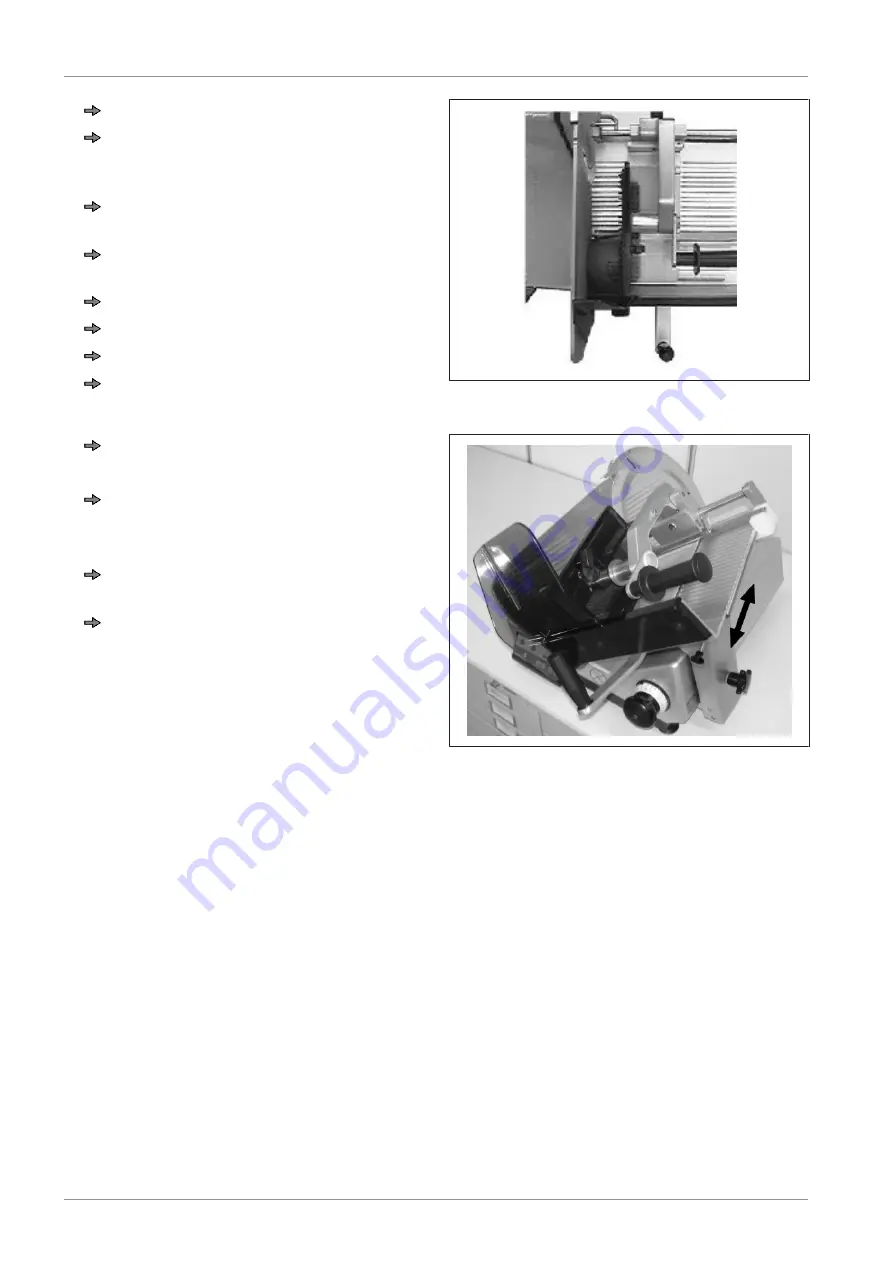

For tied product ends to be cut by hand.

Place product end against the rear wall,

making sure that the original cut surface

faces the remnant holder plate.

Position the product fixation device

against the product.

Using handle, swivel in and hold product

holder.

Place product holder behind product.

Switch on machine.

Set slice thickness at knob.

Set stroke width and number of carriage

strokes or change after start.

Fig. 48: Load the product

Start carriage motor.

Slices drop on depositing area.

Stop carriage motor.

The carriage runs towards the operator,

the blade is on hold.

Once the slicing process is completed

set slice thickness to "0".

Switch off machine.

Fig. 49: Slice product

6.2.3

Manual carriage guide with servo support

The following description applies to all carriage versions, for long product or remnant

pieces:

Application:

– with product that is difficult to slice

– with low number of slices

– thick slices

The servo-motor support comes automatically into action during the manual carriage move-

ment.

The servo support can be adjusted in three steps via <SPEED> keys:

– Level 1 = light support, 1 LED lights up

– Level 2 = medium support, 2 LEDs light up, pre-set as standard

– Level 3 = max. support, 3 LEDs light up

Summary of Contents for GSP H

Page 1: ...Slicer GSP H GSP HD Instruction manual 38107010002 en ...

Page 11: ...Instruction manual GSP About this machine 38107010002 en US 11 92 ...

Page 15: ...Instruction manual GSP About this machine 38107010002 en US 15 92 ...

Page 88: ...Attachment Instruction manual GSP 88 92 38107010002 en US 10 Attachment ...