Gas Pressure Fryer

Maintenance

28

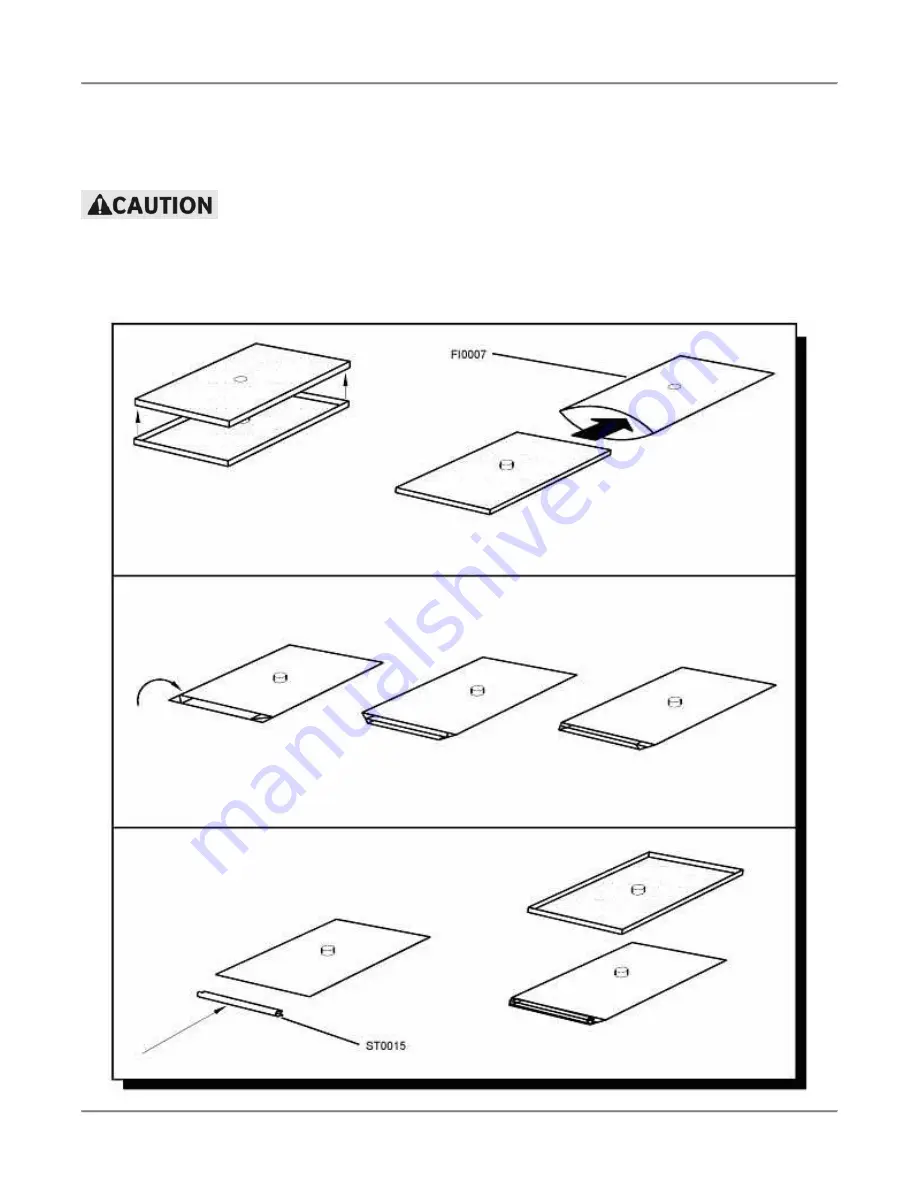

Filter Pad Replacement

The filter pad must be replaced daily. If the shortening has a milky color when it is pumped into the pot, the filter

pad should be replaced immediately.

If the filter pad is not properly closed, breading crumbs will get through the pad opening

and clog the pump. Ensure that the filter pad is properly closed upon replacement.

1. Place the filter screen inside the filter pad.

2. Fold the end of the pad and seal with the bag clip.