Ventless Hood System

Maintenance

19

Cleaning the Grease Baffle

1. Shut down the unit.

2. Locate the thumbscrews and retaining frame at the top of the grease baffle.

3. With one hand, hold the baffle to prevent it from dropping. With the other hand, loosen the

thumbscrews and slide the retaining frame forward.

4. Slowly lower the top end of the baffle until it clears the retaining frame.

5. Spray the grease baffle with degreasing type soap.

6. Rinse with hot water; dry, and replace in hood.

Replacing the Particle/Odor Filter

1. Shut down the unit.

2. Open the filter door on the front of the unit by rotating the handle counter-clockwise.

3. Slide the used filter out of the unit.

4. Remove the replacement filter from the plastic bag.

5.

Observing the “UP” arrows on the filter, with a hand at each front corner, carefully slide the filter

into the unit.

When installing a new filter, slight resistance should be observed as the filter is

being slid into place. This resistance is generated by four (4) filter springs located

on the bottoms of the filter slides. These springs insure a proper seal at the top of

the filter. After a period of time it may become necessary to adjust the pressure

that these springs provide by lifting them slightly with your fingers.

6.

Close and latch the door.

Summary of Contents for FH-28CT COUNTERTOP

Page 1: ...CS TM 041 01 Revised 04 17 13 Ventless Hood System MODEL FH 28CT COUNTERTOP Service Manual ...

Page 11: ...Ventless Hood System Installation 9 Figure 1 ...

Page 12: ...Ventless Hood System Installation 10 Figure 2 ...

Page 13: ...Ventless Hood System Installation 11 Figure 3 Right Side Pull Station Mounting ...

Page 14: ...Ventless Hood System Installation 12 Figure 4 Left Side Pull Station Mounting ...

Page 15: ...Ventless Hood System Installation 13 Figure 5 Complete Pull Station Mounting ...

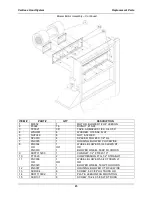

Page 24: ...Ventless Hood System Replacement Parts 22 Figure 7 Blower Motor Assembly ...

Page 26: ...Ventless Hood System Replacement Parts 24 Figure 8 Right Side Cabinet Assembly ...

Page 28: ...Ventless Hood System Wiring Diagrams 26 Wiring Diagrams ...