Getting the most out of your tool.

Please take time to read this manual and pay particular attention to the safety rules we’ve provided for

your protection. Don’t forget to send in your owner’s registration card. If you have any questions

about your tool please call:

1-800-9-BD TOOL

(1-800-923-8665)

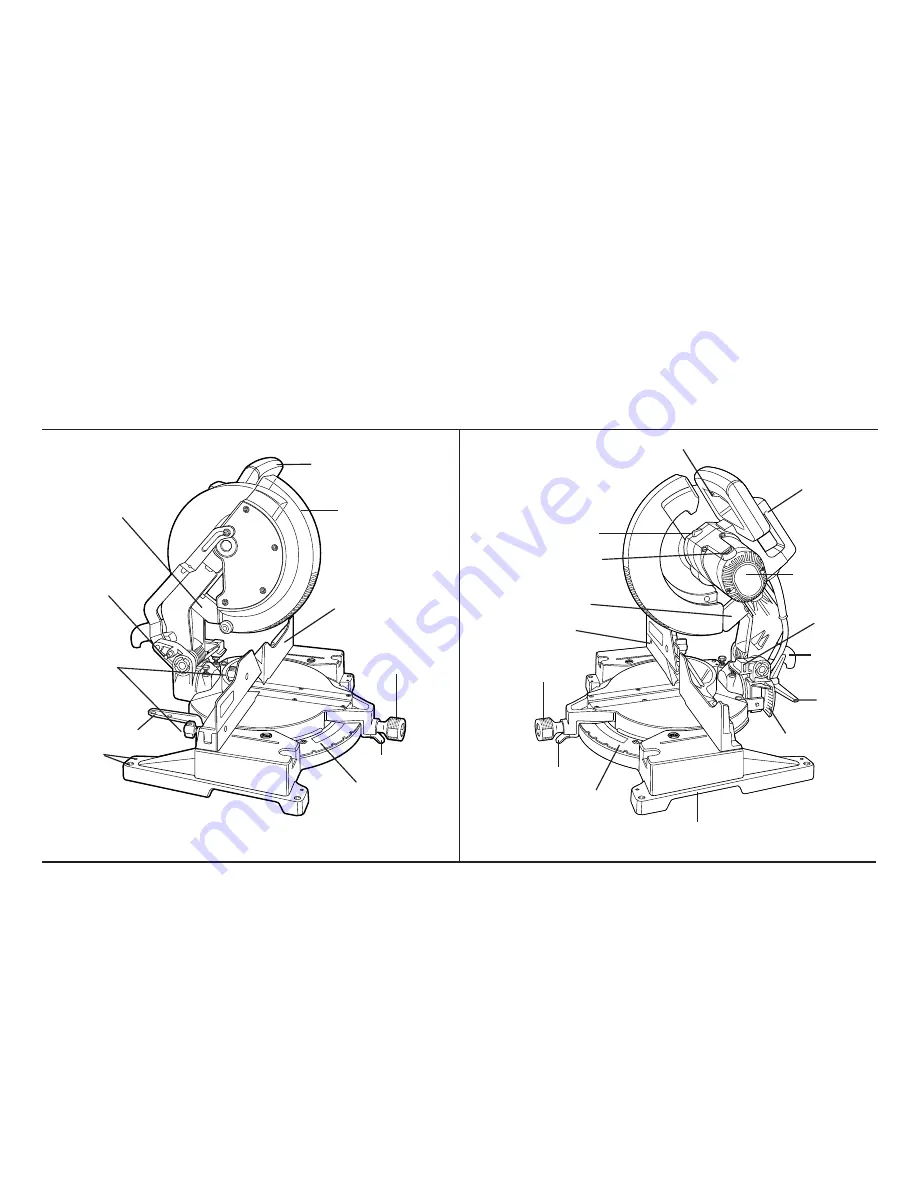

REAR LOWER GUARD

OPERATING HANDLE

GUARD

RIGHT SIDE

FENCE

MITER LATCH

MITER SCALE

LOCK DOWN PIN

BLADE WRENCH

MITER CLAMP KNOB

BENCH

MOUNTING

HOLES

REAR LOWER GUARD

BRUSH INSPECTION CAP

LEFT SIDE OF FENCE

MITER CLAMP

KNOB

MITER LATCH

MITER SCALE

HAND INDENTATION

DUST SPOUT

MOTOR HOUSING

CARRYING HANDLE

SPINDLE LOCK BUTTON

LEFT SIDE FENCE

CLAMPING

KNOBS

TRIGGER SWITCH

BEVEL CLAMP

KNOB

BEVEL SCALE

BEVEL STOP