7

ENGLISH

(Original instructions)

Torque/speed range

Non-working position used only to switch between

low speed, high speed and high torque.

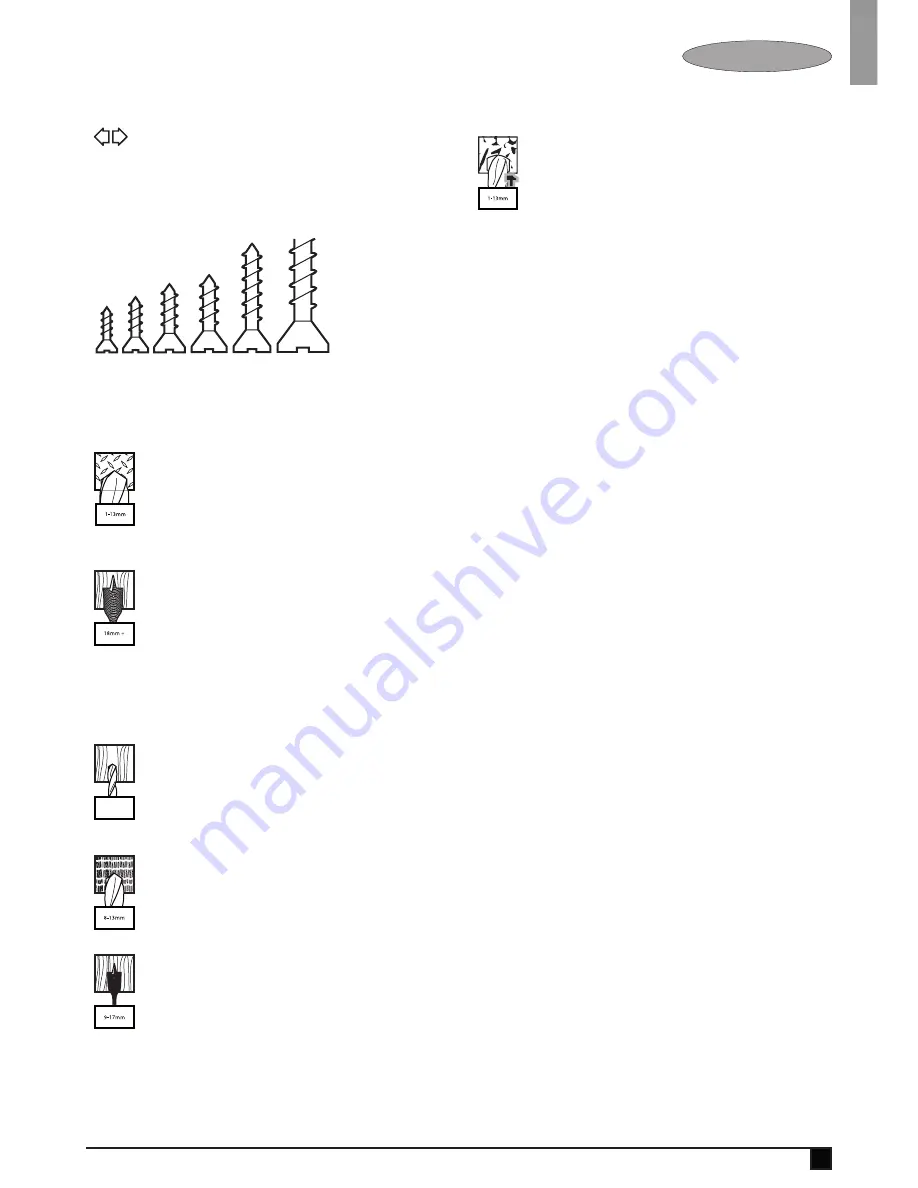

Screwdriving applications

Torque range:

low torque for

small screws

and high torque

for large

screws.

High toque drilling applications

Large drill bits in steel

Large spade bits in wood

High speed drilling applications

1-8mm

Small diameter drill bits in wood, plastic and

metal.

Large diameter drill bits in wood, plastic, metal.

Small spade bits in wood

Hammer drilling applications

Hammer drilling in concrete.

(ASL148 & ASL188 only)

Drilling/screwdriving

u

Select forward or reverse rotation using the forward/

reverse slider (2).

u

To switch the tool on, press the switch (1). The tool speed

depends on how far you press the switch.

u

To switch the tool off, release the switch.

LED light

The LED light (8) is activated automatically when the trigger is

depressed. The LED will illuminate when the trigger is partially

depressed, before the unit begins running. The LED will also

illuminate when the trigger is depressed and the forward/

reverse slider (2) is in the locked off position (central position).

Hints for optimum use

Drilling

u

Always apply a light pressure in a straight line with the drill

bit.

u

Just before the drill tip breaks through the other side of the

workpiece, decrease pressure on the tool.

u

Use a block of wood to back up workpieces that may

splinter.

u

Use spade bits when drilling large diameter holes in wood.

u

Use HSS drill bits when drilling in metal.

u

Use masonry bits when drilling in soft masonry.

u

Use a lubricant when drilling metals other than cast iron

and brass.

u

Make an indentation using a centre punch at the centre of

the hole to be drilled in order to improve accuracy.

Screwdriving

u

Always use the correct type and size of screwdriver bit.

u

If screws are difficult to tighten, try applying a small

amount of washing liquid or soap as a lubricant.

u

Always hold the tool and screwdriver bit in a straight line

with the screw.

Maintenance

Your Black & Decker tool has been designed to operate over a

long period of time with a minimum of maintenance.

Continuous satisfactory operation depends upon proper tool

care and regular cleaning.

Summary of Contents for ASL146

Page 1: ...ASL146 ASL148 ASL186 ASL188 ...

Page 2: ...2 A C B D E F ...

Page 96: ......

Page 97: ......

Page 98: ......