24

ENGLISH

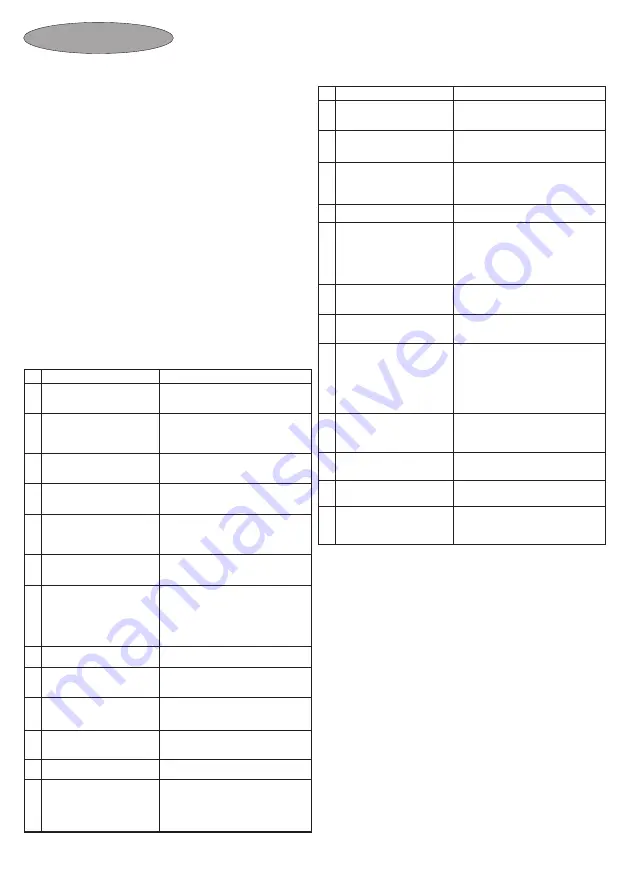

Problem

Code

19, 24

Problem

High temperature of the compressed air

Code

5, 6, 8, 9, 10, 11, 12, 13, 20

Problem

Compressor operate ininterruptedly

Code

6, 8, 13, 25

Problem

Code

6, 10, 12

Problem

Lubricant oil with unusual color

Code

10, 15, 16, 21

Problem

Insufficient pressure for required work

Code

15, 18, 24

Problem

Air leakage through relief valve of pressure switch or

compressor unit (when assembled), with compressor

operating from more than 1 (one) minute (valve closes above

20 psi (1.3 bar))

Code

25

Tank pressure increases quickly or too frequent starts

(The normal number of starts is roughly 6 an hour)

Excessive consumption of lubricating oil

(Compressors usually use more oil in the first 200 working

hours until rings are smoothly adjusted)

POSSIBLE CAUSE

POSSIBLE SOLUTION

1

Voltage drop or electrical

supply is out

Check the installation and/or wait

for the electrical supply stabilization

2

Damaged electric motor

Send it to the nearest

Black&Decker

Authorized

Service Center

3

Tank is full of air

Electric motor will start as soon as

the pressure in the tank decreases

4

Installation fuse has

burned out

Find out the burning cause

(see Table 2 - page 23)

5

Check valve does not seal

because of impurities

Send the compressor to the

nearest

Black&Decker

Authorized Service Center

6

The demand is above the

compressor’s capacity

Check the compressor’s capacity

7

Thermal protector tripped

(Picture 11 - page 25)

Turn compressor off, wait for 5 (five)

minutes and reset the protector.

If tripping is frequent, look for the

nearest

Black&Decker

Authorized

Center

8

Filter clogged

Replace it

9

Air leakage in the

compressor

Re-fasten bolts and/or fittings

10

High ambient temperature

(max. 40°C or 104°F)

Improve local conditions

11

Valve plate joint is broken

Look for the nearest

Black&Decker

Authorized Center

12

Wrong oil or low oil level

Change oil

13

Carbonized valve plate

Clean it every 1000 working hours

or 12 months at your nearest

Black&Decker

Autorized Service

Center.

POSSIBLE CAUSE

POSSIBLE SOLUTION

14

15

16

17

18

19

20

21

22

23

24

25

Deficient or inadequate

electrical supply

Operating in a

non-adequate environment

Have a specialized technician

check it

Improve local conditions

The oil change did not

occur at the recommended

interval

See Table 4 - page 25 (Preventive

maintenance) the oil change

intervals

Loose fastening elements

Find and re-fasten them

Continuous air leakage

through pressure switch’s

relief valve when

compressor shuts off

(Picture 11 - page 25).

Send compressor to the nearest

Black&Decker

Authorized Center

Send compressor to the nearest

Black&Decker

Authorized Center

Excess water in the tank

Drain the tank through the drain as

indicated in Picture 8 - page 24

Too much dust and paint

on the compressor

Clean the compressor externally

Water is mixed with the oil

(milky coloration)

Change the lubricant oil and run

your pressure compressor for

15 min, at a maximum pressure of

100 psi (7.0 bar). This will remove

any internal condensation signs

inside pump

Ambient temperature

below minimum

recommended 5°C (41°F)

Run the equipment above 5°C

(41°F)

Operating too long below

pressure of 60 psi (4.0 bar)

Compressed air consumption

higher than compressor’s flow

Pressure regulator valve

not adjusted

Relief valve not seal

because of impurities

(Picture 11 - page 25)

Adjust it (Picture 8 - page 24)

COD

COD