ENGLISH

9

(Original instructions)

u

Before measuring for the proper viscosity, stir the material

thoroughly.

u

Dip the viscosity cup (13) into the material being sprayed

u

With the viscosity cup (13) held over the material con-

tainer, measure the amount of time it takes for the stream

stream out of the bottom of the viscosity cup (13) (2

the thinning table for information on the thinning required

for different materials.

u

If material needs thinning, add the appropriate liquid thin-

ning material recommended by the manufacturer.

u

It is possible to spray latex paint with this unit, however,

the required thinning may exceed material manufacturer's

recommendation. Thin latex paint so that it runs through

viscosity cup (13) in under 2 minutes. The operator should

project when spraying a material that requires more than 2

minutes to run through the viscosity cup (13).

Hints for optimum use

Preparation tips

u

Always stir and strain the material thoroughly before use.

u

With any spraying job you should always ensure that

you have properly prepared the surface to get the best

grease. Lightly pressure wash decks or exterior surfaces

and ensure that they are dry before spraying.

u

Even though HVLP sprayers have very little overspray,

it is recommended that you mask all edges and other

anything else in the spraying area that you wish to remain

untouched.

u

Skin that forms on the top of paint can clog the sprayer.

Remove skin before mixing. Strain with a funnel with a

that could clog system.

u

Before starting have gloves, paper towels, rags etc. avail-

able for unexpected spills.

u

Practice spraying on a piece of scrap material such as

cardboard to test your spray pattern and become familiar

u

Ensure surface to be sprayed is free of dust, dirt, and

grease.

u

Ensure spray area is clean and free of dust that could be

blown onto newly sprayed surfaces.

u

Cover any areas not intended to be sprayed.

u

Always spray from a minimum of 25mm to a maximum of

u

A commonly used method for spraying a large surface

is the “crisscross” pattern. This is done by spraying in

horizontal strips and then crossing over these strips with

vertical strips.

u

To get an even spray distribution, always keep your arm at

-

u

Maintain smooth and consistent speed which will help

avoid inconsistencies. Begin spraying after the pass has

begun and release trigger before stopping the pass.

u

Avoid spraying too heavily in any one area. Several lighter

coats are better than one heavy coat which can lead to

knob regulates the amount of liquid that can be sprayed.

liquid. Turning the knob counterclockwise decreases the

brush on hand to smooth them out.

u

Turn the power unit off and place the sprayer in the built-in

dock of the power unit when not spraying for any length of

time.

Maintenance and cleaning

Your Black & Decker corded appliance has been designed to

operate over a long period of time with a minimum of main-

tenance. Continuous satisfactory operation depends upon

proper appliance care and regular cleaning.

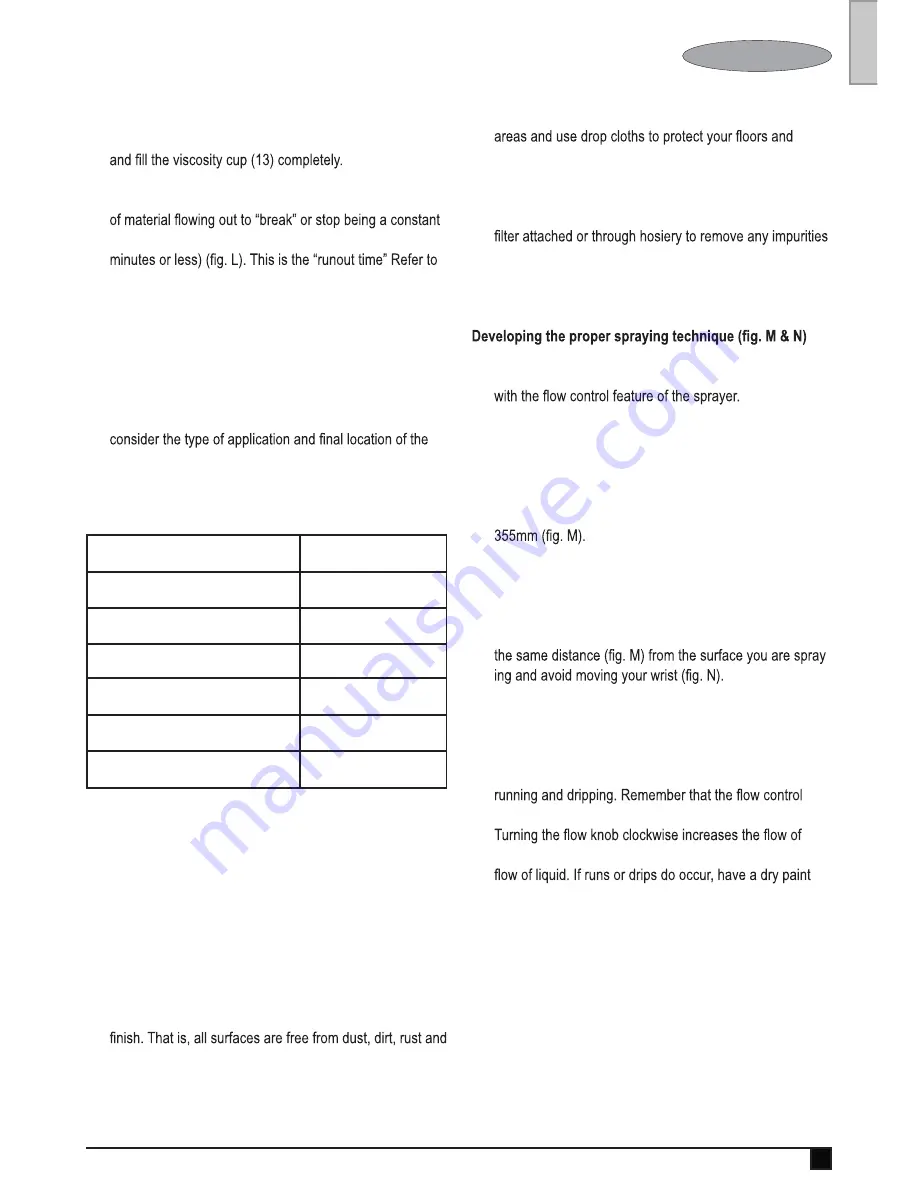

Material compatibility table

MATERIAL

LATEX

ENAMEL

OIL BASED PRIMERS

OIL BASED VARNISHES

CLEAR STAINS

SEMI- TRANSPARENT STAINS

COMPATIBLE

YES

YES

YES

YES

YES

YES

Important Note: Ensure the material used passes viscosity test.

Using the viscosity cup to test, full cup should be emptied

within two (2) minutes.

Summary of Contents for HVLP400

Page 1: ...HVLP400 English 06 www blackanddecker com ...

Page 2: ...2 A B C D E F ...

Page 3: ...3 G H I J K L ...

Page 4: ...4 M N O P Q R I J ...

Page 5: ...5 T U S ...