8

ENGLISH

(Original instructions)

guard for cutting operations part numbers 1004702-27 and

1004702-28 for KG711/KG911 and KG912/KG752 is available

and can be obtained from BLACK+DECKER service centres.

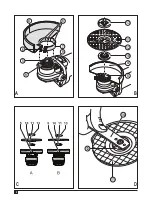

Fitting and removing the guard (fig. A)

K

G

912 Only

The tool is supplied with a guard intended for cutting off

purposes only. If the unit is intended to perform grinding

operations, a guard specific for this operation must be fitted. A

suitable guard for grinding operations part number

1004702-36

is available and can be obtained from BLACK & DECKER

service centres.

Fitting

u

Place the angle grinder on a table, spindle (5) up.

u

Align the lugs (8) with the notches (9).

u

Press the guard (4) down and rotate it to the required

position.

u

Securely tighten the screw (6).

u

To remove the guard, slacken the screw

Warning!

Never use the tool without the guard.

Fitting the side handle

u

Screw the side handle (2) into one of the mounting holes

in the tool.

Warning!

Always use the side handle.

Fitting and removing grinding or cutting discs

(fig. B - D)

Always use the correct type of disc for your application.

Always use discs with the correct diameter and bore size (see

technical data).

Fitting

u

Fit the guard as described above.

u

Place the inner flange (10) onto the spindle (5) as shown

(fig. B). Make sure that the flange is correctly located on

the flat sides of the spindle.

u

Place the disc (11) onto the spindle (5) as shown (fig. B).

If the disc has a raised centre (12), make sure that the

raised centre faces the inner flange.

u

Make sure that the disc locates correctly on the inner

flange.

u

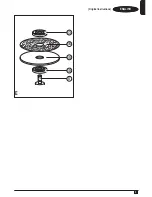

Place the outer flange (13) onto the spindle. When fitting

a grinding disc, the raised centre on the outer flange must

face towards the disc (A in fig. C). When fitting a cutting

disc, the raised centre on the outer flange must face away

from the disc (B in fig. C).

u

Keep the spindle lock (3) depressed and tighten the outer

flange using the two-pin spanner (14) (fig. D).

Removing

u

Keep the spindle lock (3) depressed and loosen the outer

flange (13) using the two-pin spanner (14) (fig. D).

u

Remove the outer flange (13) and the disc (11).

Fitting and removing sanding discs (fig. D & E)

For sanding, a backing pad is required. The backing pad is

available from your BLACK+DECKER dealer as an accessory.

Fitting

u

Place the inner flange (10) onto the spindle (5) as shown

(fig. E). Make sure that the flange is correctly located on

the flat sides of the spindle.

u

Place the backing pad (15) onto the spindle.

u

Place the sanding disc (16) onto the backing pad.

u

Place the outer flange (13) onto the spindle with the raised

centre facing away from the disc.

u

Keep the spindle lock (3) depressed and tighten the outer

flange using the two-pin spanner (14) (fig. D). Make sure

that the outer flange is fitted correctly and that the disc is

clamped tightly.

Removing

u

Keep the spindle lock (3) depressed and loosen the outer

flange (13) using the two-pin spanner (14) (fig. D).

u

Remove the outer flange (13), the sanding disc (16) and

the backing pad (15).

Use

Warning!

Let the tool work at its own pace. Do not overload.

u

Carefully guide the cable in order to avoid accidentally

cutting it.

u

Be prepared for a stream of sparks when the grinding or

cutting disc touches the workpiece.

u

Always position the tool in such a way that the guard

provides optimum protection from the grinding or cutting

disc.

Switching on and off

u

To switch on, slide the on/off switch (1) forward. Note that

the tool will continue running when you release the switch.

u

To switch off, press the rear part of the on/off switch.

Warning!

Do not switch the tool off while under load.

Soft Start Feature

The soft start feature allows a slow speed build-up to avoid

an initial jerk when starting. This feature is particularly useful

when working in confined spaces.

No-Volt

The No-volt function stops the grinder restarting without the

switch being cycled if there is a break in the power supply.