13

CHAPTER 3: Installation

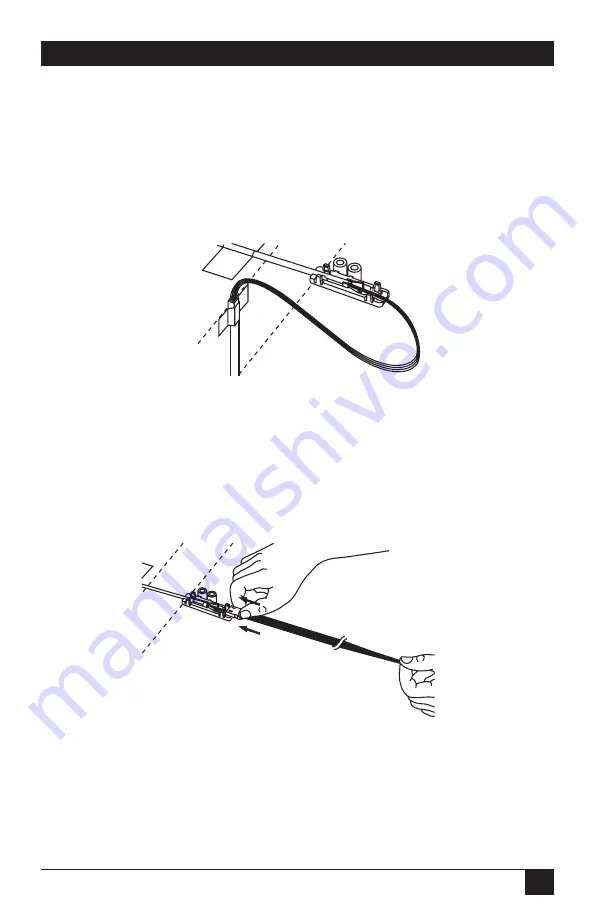

6. Carefully pull the fibers out of the tube ends to take up most of the excess

length between the Buffer Tube Fanout body and the 900-µm assembly.

NOTE

Leave a small fiber loop between the Buffer Tube Fanout body and the

900-µm assembly to prevent fiber breakage during later steps in this

procedure (see Figure 3-8

).

Figure 3-8. Leaving a Loop to Prevent Fiber Breakage.

7. Untape the 900-µm assembly from the table edge. Carefully slide the assembly

while gently pulling the bare fibers protruding from the 900-µm tube ends

until the assembly is above the fanout body (see

Figure 3-9

).

Figure 3-9. Pulling the Assembly.

At times the fibers will twist as a group when sliding the 900-µm assembly

toward the buffer tube. Rotate the 900-µm assembly opposite the direction of

twist until the fibers straighten out. Severe twists left in the fibers could

exhibit long term micro-bending effects on the fiber performance and add

loss.

Summary of Contents for EFN06-24

Page 3: ......