17

RADIAL ROCKET Item code: BH155

.

Instruction Manual

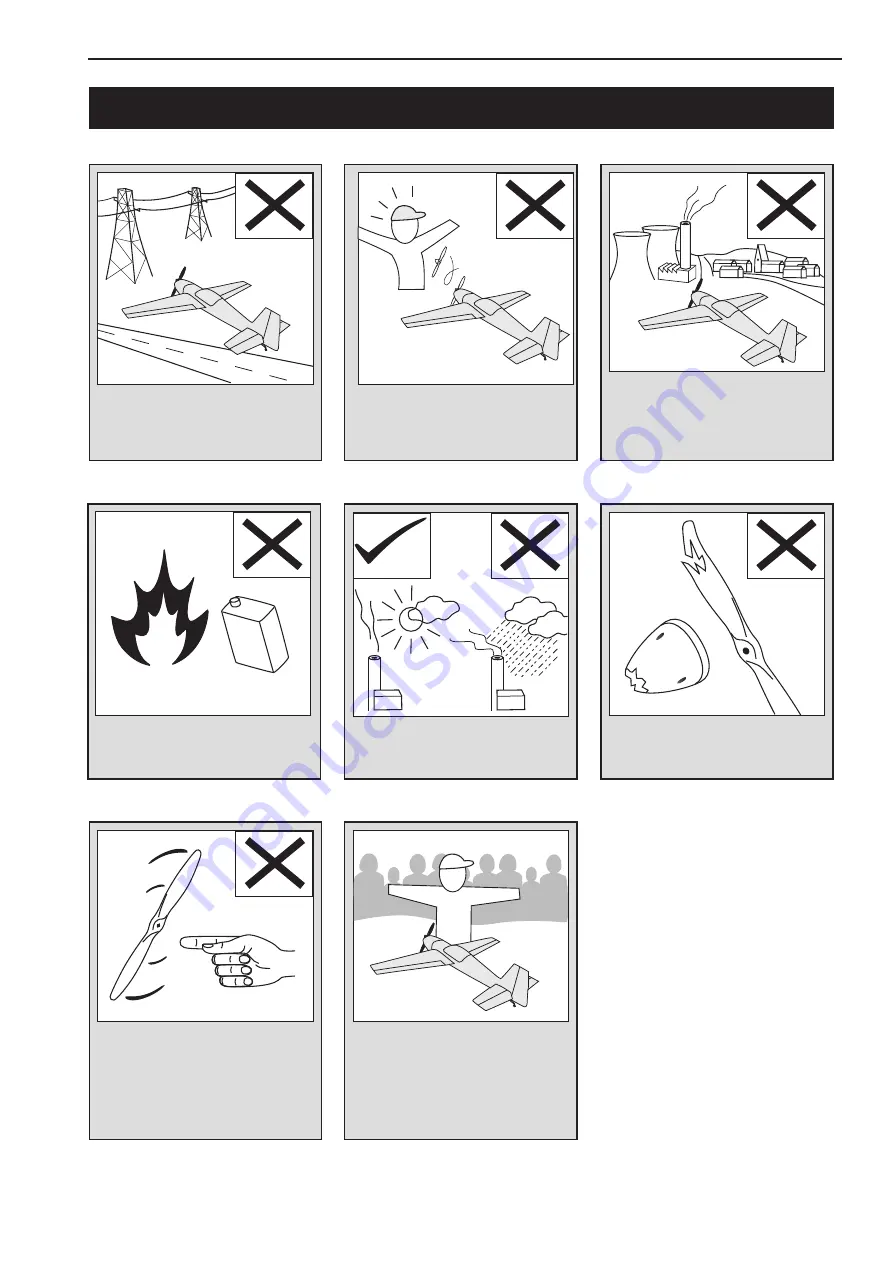

NEVER

fly in wet conditions or on

windy or stormy days.

I/C FLINgT WARNINgS

THE PROPELLER IS DANgEROUS.

Keep fingers, clothing (ties, shirt

sleeves, scarves) or any other loose

objects that could be caught or

drawn in, away from the propeller.

Take care at

ALL

times.

NEVER

use damaged or deformed

propellers or spinners.

DO NOT

dispose of empty fuel

containers on a fire, this can lead to

an explosion.

Keep all onlookers (especially small

children and animals) well back

from the area of operation. This is

a flying aircraft, which will cause

serious injury in case of impact with

a person or animal.

NEVER

fly near power lines,

aerials or other dangerous areas

including airports, motorways etc.

ALWAYS

adjust the engine from

behind the propeller, and do not

allow any part of your body to be in

line with the propeller.

Always operate in open areas, away

from factories, hospitals, schools,

buildings and houses etc.

NEVER

fly your aircraft close to people or

built up areas.