21

ROCKWELL AERO COMMANDER SHRIKE

-Item code:

BH90

INSTRUCTION MANUAL.

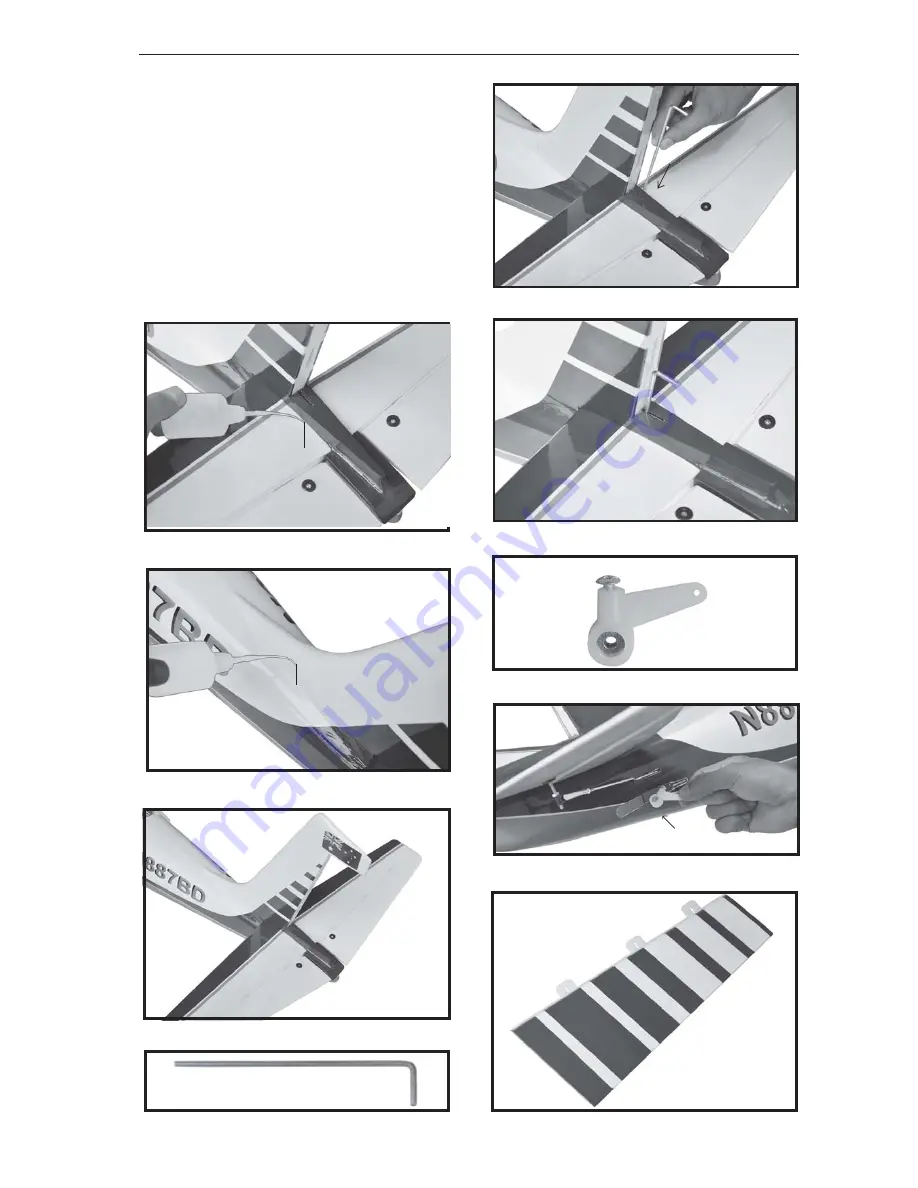

5.) When you are sure that everything is a

aligned correctly, mix up a generous amount

of 30 minute epoxy. Apply a thin layer to the

slot in the mounting platform and to the verti-

cal stabilizer mounting area. Apply epoxy to

the lower rudder hinge. Set the stabilizer in

place and re-align. Double check all of your

measurements once more before the epoxy

cures. Remove any excess epoxy using a

paper towel and rubbing alcohol and hold the

stabilizer in place with T-pins or masking tape.

Allow the epoxy to fully cure before proceed-

ing.

C/A glue.

C/A glue.