6

BLACKRIDGE

2.5HP AIR COMPRESSOR

BLACKRIDGE

2.5HP AIR COMPRESSOR

7

To turn your air compressor ON

Lift up the red ON / OFF button on top of

the pressure switch. Pic. 9.

To turn your air compressor OFF

Push down the red ON / OFF button on

top of the pressure switch. Pic. 10.

PIC. 9

PIC. 10

3. YOU’RE IN CONTROL

Running in your new air compressor

Your new air compressor requires running in.

1. Plug the power cord into a standard 240V 10Amp

AC power point.

2. Open the tank drain tap.

3. Start the air compressor using the ON / OFF button.

4. Run the air compressor for approximately 1 minute.

This ensures that the air compressor is fully lubricated under

no load.

After the 1 minute stop the air compressor using the ON / OFF

button. Allow to cool approximately 5 minutes. Recheck the oil

level and top up if needed.

Before starting your air compressor again ensure tank drain tap

is closed.

WARNING!

BEFORE RUNNING IN ENSURE

THAT THE FOLLOWING HAS BEEN COMPLETED:

THE OIL BREATHER HAS BEEN FITTED, THE OIL

LEVEL IS CORRECT AND THE AIR COMPRESSOR

HAS BEEN FULLY ASSEMBLED.

WARNING!

ALWAYS ENSURE THAT YOU PLUG

YOUR AIR COMPRESSOR INTO A STANDARD

240V AC POWER POINT. NEVER USE AN

EXTENSION CORD, USE A LONGER AIR HOSE

IF YOU NEED TO GET CLOSER TO YOUR WORK

AREA.

4. USING YOUR PRODUCT

Positioning your new air compressor

Always position air compressor on level ground.

Always position air compressor away from work area so

that the air compressor does not get covered in dust,

water or paint.

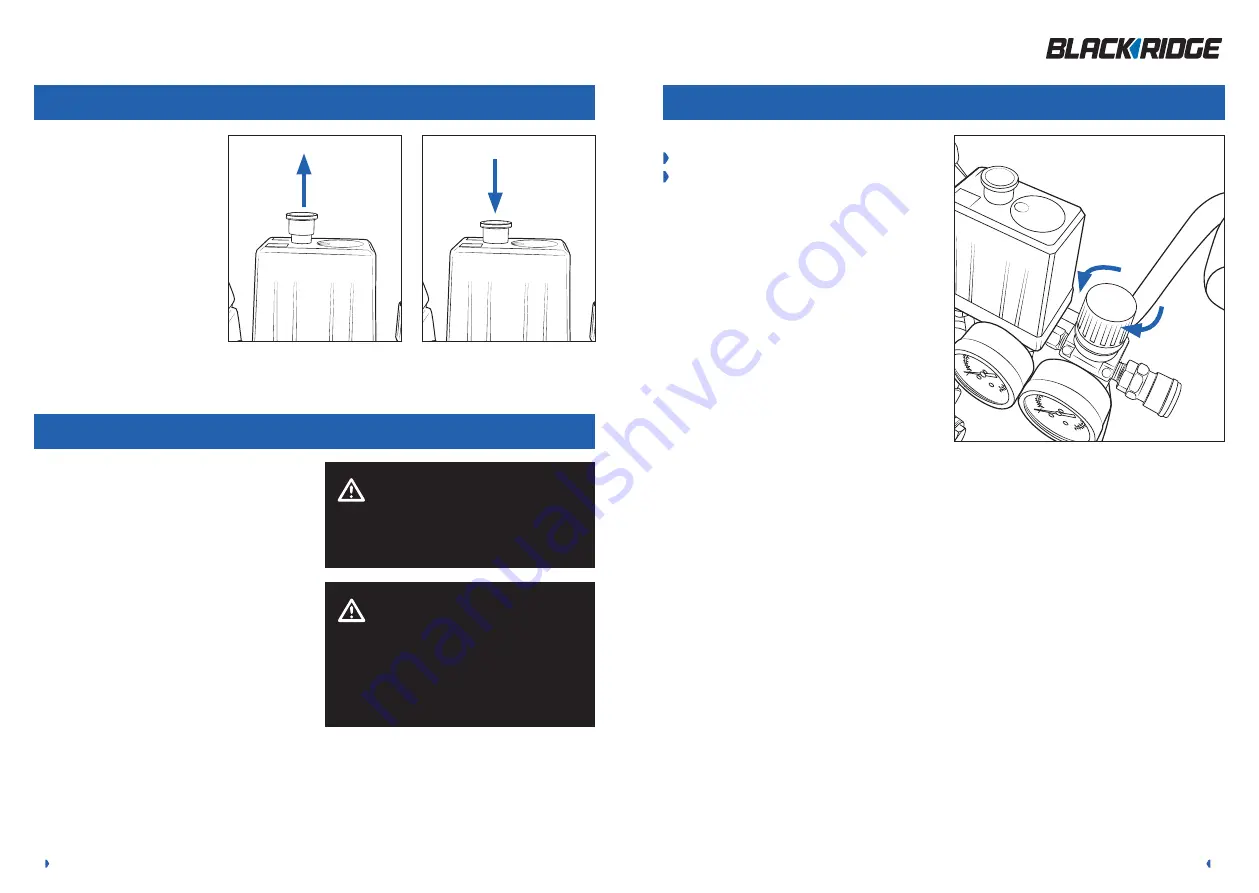

Adjusting the pressure

Pumping starts at (minimum) 85PSI and stops at (maximum)

115PSI. Once the initial pump up stage has finished you can

adjust the outlet air pressure to the tool’s recommended working

pressure. Pic. 11.

To adjust the outlet air pressure, use the red coloured regulator

knob and check the pressure on the outlet pressure gauge. If the

pressure needs to be lower, turn anti clockwise. If the pressure

needs to be higher, turn clockwise. Use the gauge to ensure you

set the correct working pressure.

Note: Different air tools require different operating pressures.

Always check with the tool manufacturer if unsure.

When you’re finished

1. Turn your air compressor OFF, using the ON/OFF button.

2. Turn the power point OFF and disconnect the power lead.

3. Disconnect your air tools and air hose.

4. Clean your air hose and air tools.

5. Store your air hose and air tools in a secure well

ventilated cabinet.

6. Slowly open the tank drain tap. This allows excess air

and moisture, water, to vent.

7. Leave the tank drain tap open. This allows any moisture

to drain while the air compressor is stored.

PIC. 11

Decrease

Increase

ON

OFF