4

OPERATION

Lifting

1. Follow the vehicle manufacturer’s recommended guidelines for lifting. Engage the emergency brake and chock

each unlifted wheel in both directions to prevent inadvertent vehicle movement.

2. Close the release valve by turning the handle clockwise until firm resistance is felt.

3. Refer to the vehicle manufacturer owner’s manual to locate approved lifting points on the vehicle. Center jack

saddle under lift point.

4. Verify lift point, then pump handle to contact lift point. To lift, pump handle until load reaches desired height.

5. Transfer the load

immediately

to appropriately rated jack stands.

Lowering

WARNING:

Clear all tools and personnel before lowering vehicle. Open release valve slowly. The further

the pump handle is turned counter-clockwise, the faster the load will descend. Maintain control of load at all

times.

1. Raise load high enough to clear the jack stands.

2. Remove jack stands.

3. Turn the handle counter-clockwise, but no more than 1/2 full turn.

If load fails to lower:

a. Use another jack to raise the vehicle high enough to reinstall jack stands.

b. Remove the malfunctioning jack and then the jack stands.

c. Use the functioning jack to lower the vehicle.

4. After removing jack from under the vehicle, fully lower the saddle to reduce ram exposure to rust and contamination.

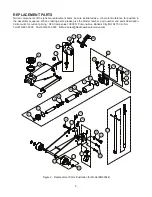

MAINTENANCE

NOTICE:

Use premium quality hydraulic jack oil. Avoid mixing different types of fluid and NEVER use brake fluid,

turbine oil, transmission fluid, motor oil or glycerin. Improper fluid can cause premature failure of the jack and the

potential for sudden and immediate loss of load.

Adding oil

1. With saddle fully lowered set jack in its upright, level position. Remove oil filler plug.

2.

Fill with oil until ~3/16" above the inner cylinder as seen from the oil filler hole. Reinstall the oil filler plug.

Changing oil

For best performance and longest life, replace the complete fluid supply at least once per year.

1. With saddle fully lowered, remove the oil filler plug.

2. Lay the jack on its side and drain the fluid into a suitable container.

NOTICE.

Dispose of hydraulic fluid in accordance with local environmental regulations.

3. Fill with oil until ~3/16" above the inner cylinder as seen from the oil filler hole. Reinstall oil filler plug.

Lubrication

A periodic coating of light lubricating oil to pivot points, axles and hinges will help to prevent rust and assure that

wheels, casters and pump assemblies move freely.

Cleaning

Periodically check the pump piston and ram for signs of rust or corrosion. Clean as needed and wipe with an oily cloth.

NOTICE:

Do not use sandpaper or abrasive material on ram or pump piston surfaces.

Storage

When not in use, store the jack with saddle fully lowered.

!